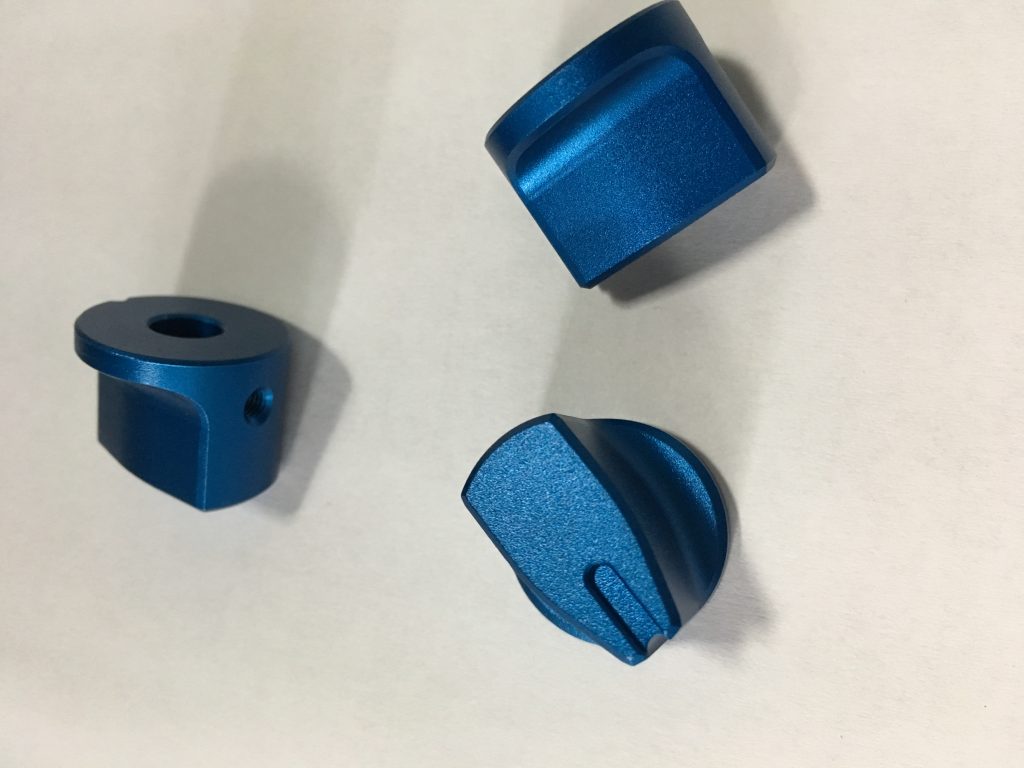

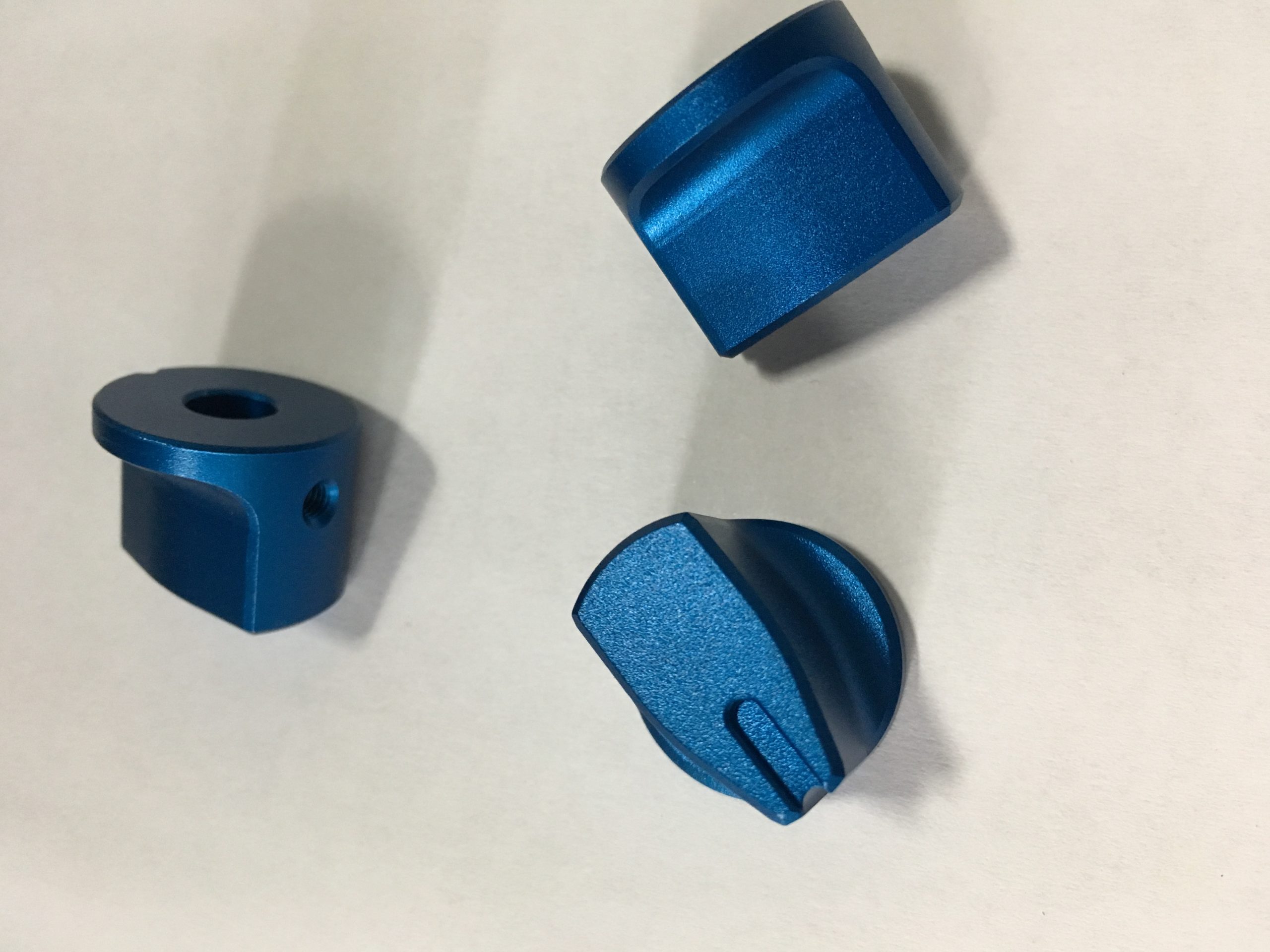

Sand Blasted and Anodized CNC Turning and CNC Milling Aluminum Knobs

- Material: AL 6061

- Size: D19*15 mm

- Process: CNC turning and CNC milling

- Surface treatment: Sand Blasted+Red/Blue Anodize

Why Are Sand Blasting and Anodizing Two Common Surface Treatments Applied to CNC Turning and CNC Milling Aluminum Knobs?

- Enhanced Appearance: Sand blasting creates a uniform, textured surface that can improve the aesthetic appeal of aluminum knobs. It can also remove imperfections and provide a consistent base for anodizing.

- Improved Corrosion Resistance: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance. This makes anodized aluminum knobs more durable and less susceptible to oxidation and wear.

- Increased Hardness and Wear Resistance: Anodizing can also increase aluminum’s hardness and wear resistance, making anodized knobs more durable and less prone to scratches and dents. This is particularly beneficial for knobs subjected to frequent handling or harsh environments.

- Variety of Colors and Finishes: Anodizing can produce a wide range of colors and finishes, allowing for customization to match specific design requirements or aesthetic preferences. This versatility makes anodized aluminum knobs suitable for various applications, from industrial equipment to consumer electronics.

- Electrical Insulation: Anodized aluminum knobs provide electrical insulation, making them ideal for applications where electrical conductivity is not desired. This property is particularly valuable in electrical components or knobs that may come into contact with electrical circuits.

What Are the Advantages of Using CNC Turning and CNC Milling for Aluminum Knobs?

CNC turning and CNC milling offers several advantages for machining aluminum knobs, including high precision and accuracy, versatility, complexity and detailing, repeatability and consistency, automation and efficiency, surface finish quality, material efficiency, and reduced tool wear and maintenance.

Why Choose JTR?

Professional mass manufacturing and rapid prototyping services, such as CNC machining, die casting, 3D printing, rapid tooling and injection molding, plastic and aluminum extrusion, sheet metal prototyping, and integrating the design and development of new products, are the focus of Chongqing Jin Te Rui Machine Co., Ltd. Our superior manufacturing solutions enable us to quickly realize your design in a matter of hours. This enables you to carry out thorough testing of the product and make all the required adjustments to refine the design before starting full production.