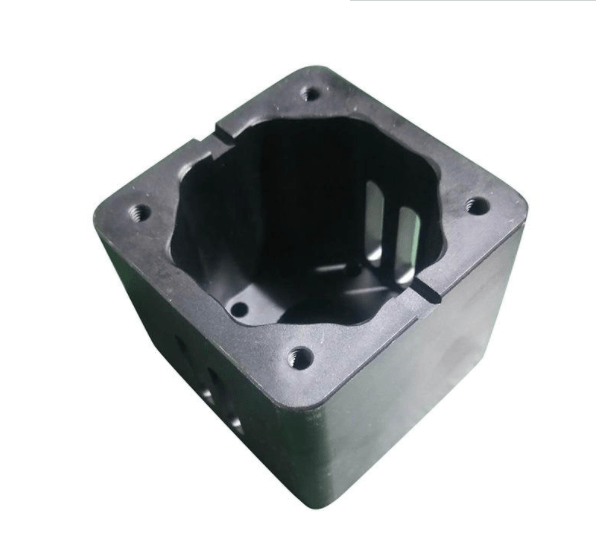

CNC Milling Steel Parts

Steel is a general term for iron-carbon alloys with a carbon content between 0.02% and 2.11% by mass. Usually, steel is combined with different alloying elements (manganese, nickel, vanadium, etc.) in the form of alloys to meet the needs of steel in different applications. Due to the characteristics of steel, CNC machining has become the first choice for machining steel materials. CNC Milling steel service can perfectly provide steel secondary machining. The service provides an enhanced definition of workpieces, such as making intricate details such as holes, grooves, and threads.

CNC Milling Materials for Steel Parts

Steel 1018

Generally referred to as light steel, 1018 is very weldable as well fit to appear solidifying procedures such as carburizing. Once carburized, this product is generally utilized for gears, worms, mold, and mildew parts.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 310 | 78 | 20 | 131 | 7.87 |

Steel 4130

When contrasted to normal moderate steel, this kind is commonly known as alloy steel due to its increased degrees of alloying components. This alloy includes chromium and also molybdenum as reinforcing aspects. These components significantly boost its mechanical homes. Applications can consist of taps, drills, and also aircraft engine mountings.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 310 | 78 | 20 | 131 | 7.87 |

Steel 4140

The properties of steel 4140 and 4130 are similar, but the carbon content has been increased. The extra carbon increases its strength and gives it better hardening properties. Chromium is also added to improve corrosion resistance. Applications for Steel 4140 include thin-walled pressure vessels, spindles, and high-strength bolts.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 655 | 80 | 25.7 | 197 | 7.85 |

Steel 4140 PH

4140PH steel is a pre-hardened version of 4140 steel with excellent mechanical strength and hardness properties. Its pre-hardening eliminates the need for post-processing heat treatment. This is ideal if you are concerned that the heat treatment of the part will cause unacceptable deformation of the finished part. Typical applications include shafts, mandrels, and dies.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 1241 | 80 | 14 | 429 | 7.8 |

Steel 4340

This steel is a high-strength, low-alloy metal. It has excellent toughness and strength and retains these properties at relatively high temperatures. Typical applications include gears, shafts, and other structural components.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 470 | 74 | 22 | 217 | 7.85 |

Steel A36

Inexpensive and easy to weld, A36 steel is a very common grade of mild steel. It is commonly used in areas such as manufacturing and steel structure support.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 250 | 79.3 | 20 | 119 | 7.85 |

Why Choose JTR CNC Milling Steel Services?

At JTR, we offer your choice of 3-, 4- or 5-axis CNC milling services, which means no matter how complex your design, you can be sure it will be accurately produced to a high standard. We match you with a trusted partner who will deliver your parts within days of your order, meaning you don’t have to compromise on price, accuracy, or efficiency when choosing a manufacturing service.

- State-of-the-art equipment. Use a multifunctional CNC machining center for production and CMM and more precise tooling for inspection.

- High affordability. Cost-effective materials and cost control throughout the process make us an economical choice.

- Multiple services. Provide CNC milling, CNC turning, EDM, finishing, hardware assembly, and more for your CNC parts.

- quality and precision. ISO 9001 certified, material certification is available, and tight tolerances are available upon your request.

- Reply and deliver. Get a free online quote as long as you submit your documents. Fast delivery time ensures that the goods are delivered on time.

Our CNC machines can handle complex operations such as small radius cuts and threaded holes while maintaining high-quality levels.

Features of Custom CNC Milling Steel Parts

- Custom CNC milling steel parts typically have higher strength and integrity, as well as greater precision.

- Custom machined parts can be manufactured much faster than many other methods.

- Because CNC Milling custom services maximize part detail, CNC custom parts are often manufactured for performance-critical industries.

- Custom parts are non-standard or not available from common suppliers.

- Some features of custom parts are not found on standard components.

- CNC machining shops usually accept small batches and can guarantee production and delivery of quality requirements within the agreed time.

- Custom CNC steel parts are often produced for specific end-use.

CNC Milling of Steel – Steel Features and Benefits

The carbon content in steel increases its strength and fracture resistance. Most steels have good machinability and weldability and can be heat-treated well. Steel is often the preferred choice for automotive, aerospace, and applications requiring high durability and performance, and CNC milling is often the manufacturing method in these industries. In terms of its advantages and advantages, steel is much stronger than many other materials, while also being very affordable.

What is CNC milling?

Typically, CNC milling or manual milling is the machining process used to produce prismatic parts. Milling cutters with rotating cylindrical heads and multiple flutes are often called end mills or end mills and can be moved along different axes to machine slots, grooves, outer contours, etc. Machine tools that perform milling are called milling cutters, and CNC milling machines are usually exponentially controlled machining centers. Milling operations include manual milling and CNC milling, which are performed in machine shops.

Advantages of CNC Milling

1. The parts have strong adaptability and flexibility and can process parts with particularly complex contours or difficult to control dimensions, such as mold parts, shell parts, etc.

2. It can process parts that cannot be processed by ordinary machine tools or are difficult to process, such as complex curved parts described by mathematical models and three-dimensional space surface parts.

3. Parts that need to be processed in multiple processes after one clamping and positioning can be processed.

4. High processing precision, stable and reliable processing quality.

5. The production automation is high, which can reduce the labor intensity of the operator. Conducive to production management automation.

6. High production efficiency.

7. In terms of cutting principle, both end milling and peripheral milling are intermittent cutting methods, not continuous cutting like turning, so the requirements for tools are higher, and they have good impact resistance, toughness, and wear resistance. sex. In dry cutting conditions, good red hardness is also required.

Try JTR Machine Out Now In Just A Few Steps

Upload your CAD files

Multiple designs for different parts can be imported at the same time to produce a single quote. In less than a minute, a detailed cost estimation appears on the screen.

Choose the process

First, select the manufacturing process you require. You can then choose from over 70 materials, both metals and plastics, and from a wide range of finishes and certifications.

Order your parts online

Once you have selected the required options, all you need to do is confirm the order and pay for it on the secure payment platform. Your design will be analyzed by engineers.

Receive your parts

Within a short amount of time, you will receive the parts you ordered directly to your shipping address. You can track your package at any time in your personal account.