In the medical sector, CNC machining is not just a step in the production process but a crucial and risky one in the medical supply chain. The choice of a CNC machining supplier for medical applications has a direct impact on product safety, regulatory compliance, and the long-term manufacturer of the product.

Medical CNC machining, unlike its general industrial counterpart, requires the highest levels of precision, material necessity, and full tracking capability. A slight deviation in tolerancing, surface finish, or improper documentation might lead to rejected shipments, postponed enforcement of laws, or expensive withdrawals. This editorial gives an insight that is mainly oriented towards procurement and points out the most important things to keep in mind when looking for precision CNC medical machining services.

Why Medical CNC Machining Is a High-Risk Procurement Category

Medical devices operate under far stricter requirements than consumer or industrial products. CNC machining for the medical industry must meet three simultaneous expectations:

- Dimensional accuracy and repeatability

- Biocompatible, medical-grade materials

- Regulatory compliance and traceability

For procurement managers, the key challenge is that CNC machining medical devices is not a one-time purchase—it is a long-term partnership decision. The machining supplier effectively becomes an extension of the OEM’s quality management system.

Typical risks include:

- Tight tolerances are not holding consistently across batches

- Material substitutions without proper certification

- Incomplete documentation during FDA or CE audits

- A prototype success that fails during volume production

Understanding these risks is the foundation for making the right sourcing decision.

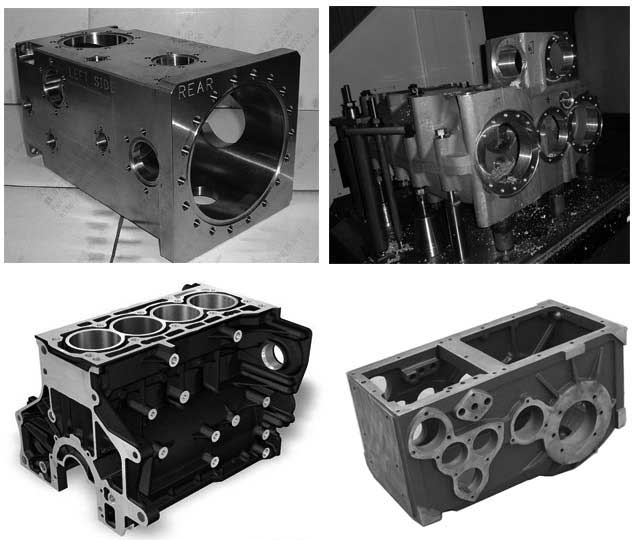

Typical Medical Applications Requiring Precision CNC Machining

There are several different uses of medical CNC machining, each of them being characterized by special and demanding technical and regulatory requirements:

- Surgery instruments, where there are requirements for very sharp edges, very smooth surfaces, and the possibility of sterilizing

- Orthopedic implants with tricky geometries and very small tolerances

- Dental implants and abutments, which must be very precisely made on a micron scale

- Parts of diagnostic equipment that must be stable in their dimensions

- Prostheses and other customized medical parts are produced in small quantities

In the case of these application domains, it is the procedures of precision CNC medical machining that are, in general, the most highly regarded for their accuracy, repeatability, and the ease with which they can be used for the making of models and for manufacturing.

Precision Requirements That Truly Matter to Medical OEMs

The axis or machine type is commonly raised by the CNC supplier, but the team that buys the machines should really just care about the manufacturing quality, and not the brand.

The key factors in the precision are:

Tolerances that are generally in the range of ±0.01 mm, ±0.005 mm, or even tighter for medical implants

- Swiss-type CNC turning for thin and long medical parts

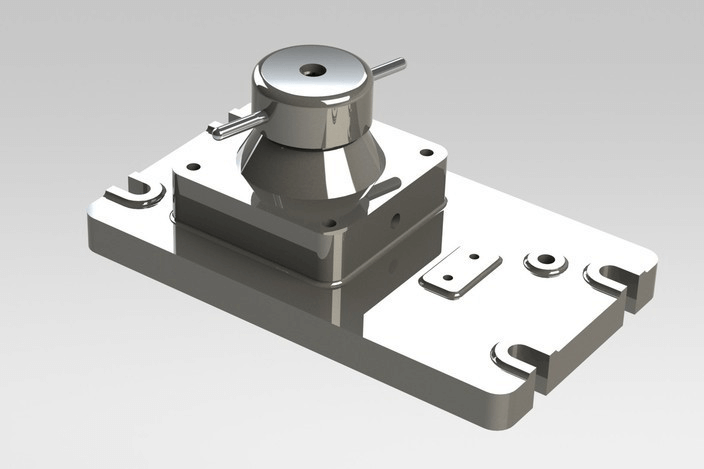

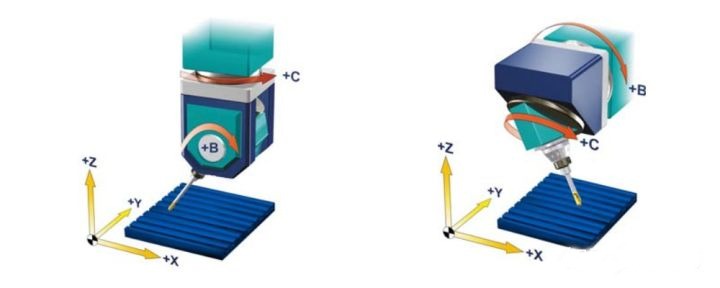

- 5-axis milling for the complicated and fewer setup geometries

- Tool life management and batch-to-batch repeatability are supported

- First part check (FPC) and as-you-go control are two other things

In the medical industry, the lessons of history suggest that the property of being both uniform and stable in the process is of greater concern than the sporadic high precision that sometimes occurs. At times like these, being able to similarly hit the tolerances for production runs in the thousands of parts is what counts much more than being the king of the prototypes only.

Medical-Grade Materials and Machining Challenges

Material selection is one of the most critical aspects of medical grade CNC machining. Common materials include:

- Titanium (Ti-6Al-4V) – widely used for implants due to strength and biocompatibility

- 316L medical-grade stainless steel – corrosion-resistant and sterilization-friendly

- PEEK and other medical polymers – lightweight and radiolucent

- Aluminum alloys – used in non-implant medical devices

Each material introduces unique machining challenges:

- Titanium generates heat and accelerates tool wear

- PEEK can deform or rebound after machining

- Surface roughness directly impacts implant performance

A qualified supplier of CNC machining medical devices must demonstrate deep material-specific experience, not just generic machining capability.

Compliance, Certification, and Traceability: Non-Negotiable Requirements

From the perspective of the purchasing department, the capability of the ISO 13485 certified quality management system for CNC machining processes, which is valid and actively implemented, is often the deciding feature, even over the price itself. The most important requirements are as follows:

- It is desirable to have a valid and actively implemented ISO 13485 certified quality management system, specifically for the CNC machining processes.

- The entire life of the material should be traceable, from stock in the raw state to the component being finished, with data supported by certified mill test reports (MTRs) as well as material certifications.

- The full device history records, including batch records and sequential documentation for lot control, should be readily available.

- The process validation protocols must be systemized and the change control procedures must follow a disciplined approach in order to validate the stability of output.

For the products under FDA jurisdiction, the CNC machining medical device suppliers, who are FDA compliant with all necessary documentation, should have no problem during the audit process if they enable the auditors to inspect with access to the full and clear company records. The procurement unit has to be stringent in verifying not only the certificates but also the ways in which the documentation is being processed, stored, and retrieved.

From Prototyping to Mass Production: Evaluating Supplier Scalability

Many medical OEMs begin with CNC machining medical prototypes, but procurement decisions should consider the entire product lifecycle.

Key evaluation questions include:

- Can the supplier maintain the same tight prototype tolerances and surface finishes during high-volume production runs?

- Is production tooling standardized and formally locked following successful validation to prevent unapproved changes?

- Does the supplier have the capacity, systems, and discipline to scale output significantly without compromising process control or quality?

Suppliers capable of both low volume CNC machining medical devices and stable mass production reduce the risk of costly supplier transitions later.

Quality Control in Precision CNC Medical Machining

Robust quality control is the backbone of medical CNC machining. Effective systems typically include:

- First Article Inspection (FAI) with full dimensional reporting.

- In-process monitoring using Statistical Process Control (SPC) methods.

- Advanced metrology with CMM (Coordinate Measuring Machine) and optical measurement systems.

- Rigorous surface finish inspection and functional verification.

- Controlled post-processing, including precision cleaning, deburring, and medical-grade packaging.

For procurement teams, process transparency is more important than individual inspection reports. A mature quality system ensures problems are detected early, not after shipment.

Common Procurement Mistakes in Medical CNC Outsourcing

Even procurement teams with lavish experience can get into trouble very easily, for example:

- Awarding business based only on the price per unit can result in really low quality, low compliance, and higher total cost of ownership.

- Thinking that by merely having an ISO certificate, a manufacturer can have the required experience in medical machining with the related materials and their standards.

- Not physically inspecting the supplier’s location and documents, and thereby failing to catch and prevent the use of substandard materials at any of the production stages, from incoming goods to the finished product.

- By doing the very same thing with prototype development that is done with full-scale production, one can only overlook the different requirements and controls of the various phases.

In order to avoid these mistakes, one must be able to direct sourcing decisions in a manner that is in line with the regulatory, quality, and long-term supply functions.

How to Choose the Right Medical CNC Machining Manufacturer

A reliable medical CNC machining manufacturer should demonstrate:

- Passionate about the precision CNC medical machining of complex, high-tolerance components, proposing the following as examples:

- Developments in the area of biocompatible, medical-grade materials (for instance, titanium, stainless steel, PEEK) were explored with the help of the candidates.

- A strong quality system (one that is ISO 13485 certified) along with the preparation of active regulatory support documentation for audits and submissions are some of the assets the team has.

- End-to-end traceability and documentation systems that are closed-loop.

- Production capacity and infrastructure that are large enough to increase together with the program.

- A sincere long-term partnership approach that, through collaboration in problem-solving and a joint endeavor for success, is aimed at the success of both parties.

For forward-thinking OEMs, the ideal supplier transcends the role of a simple manufacturer. They become a strategic manufacturing partner, invested in the mutual success and safety of the medical devices being produced.

FAQ – Medical CNC Machining for Procurement Teams

Q1: What is the medicine to bring down fever in a medically safe manner?

Most medical components demand ±0.01 mm or stricter, with some other factors playing a role.

Q2: Can FDA approve medical device manufacturing through CNC machining?

Yes, when accompanied by full documentation chemistry, and controlled processes.

Q3: Which is the most prevalent material in medical CNC machining?

Titanium, 316L stainless steel, PEEK, and medical-grade polymers.

Q4: Can medical industry get a suitable option for implantable prosthetic devices manufacturing using CNC machining?

Yes, especially for cases when there is a need for a small to medium volume of high precision made parts.