Due to their excellent strength-to-weight ratio, resistance to corrosion, and ease of machining, aluminum parts are widely applied in the automotive, aircraft, industrial machinery, electronics, and power sectors. However, the question remains the same for both engineers and buyers during the purchasing process of aluminum parts: is it cast aluminum or machined aluminum?

Apart from the casting process and machining process, there are different parameters of price, performance, accuracy, and capacity. Being familiar with these differences and having the technicality to merge them when required can highly improve one’s product quality, reduce total costs, and make delivery times faster.

A practical and engineering-oriented comparison is presented in this article to guide you to the right decision.

What Is Cast Aluminum?

Aluminum alloys are melted down, that is, the casting aluminum parts process, and then poured into the mold, where they cool and finally take the shape of the mold. Die casting, sand casting, and gravity casting are the three methods that are most predominant in the casting world. A356, A380, and ADC12 are the most used alloys for producing reliable car and non-car applications in the industry.

Key Advantages of Cast Aluminum

- High volume production is cost-effective: After the tooling is done, the price for each part is going to be greatly reduced.

- Heavy construction: It is possible to get internal cavities, ribs, and very complicated shapes all done in one pass.

- Efficient use of material: The amount of raw material wasted is much less in comparison to subtractive machining.

- Quick production cycles for the large-scale manufacturing.

Typical Applications

- Automotive housings and brackets

- Pump bodies and valve components

- Electrical enclosures

- Structural parts with moderate tolerance requirements

However, casting can introduce porosity, shrinkage, or internal defects, which may affect strength and dimensional accuracy if not properly controlled.

What Is Machined Aluminum?

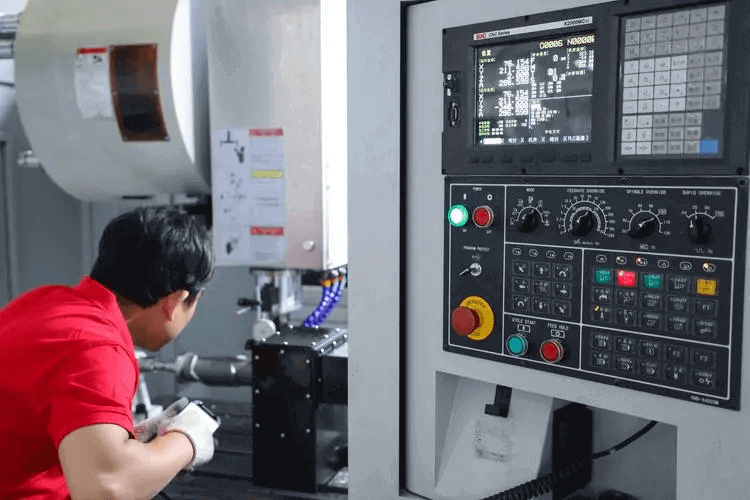

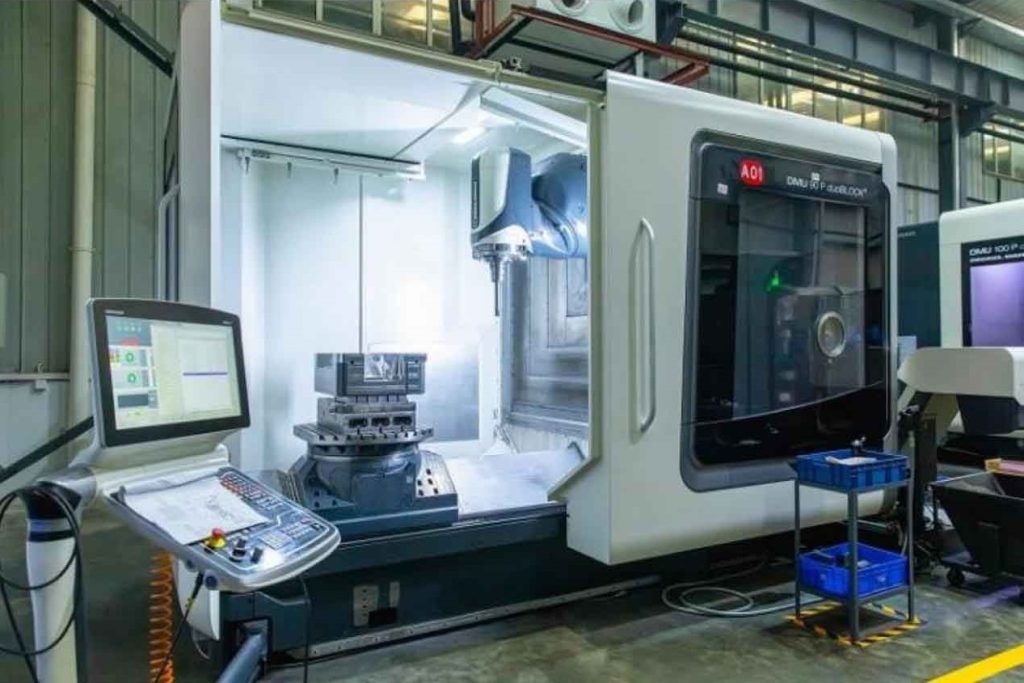

The manufacturing of aluminum parts machined to specified dimensions is done by using CNC machining processes like milling, turning, and 5-axis machining. The main material utilized for these parts is full solid aluminum stock (billet), which is usually composed of 6061-T6, 7075, or 2024 aluminum alloys.

Key Advantages of Machined Aluminum

- Very accurately done and tolerances that are very close to each other (often ±0.01 mm or better)

- The mechanical properties are great due to the uniform grain structure of the billet material

- There are no tooling costs, hence it is suitable for prototyping and low-volume production

- Great surface finish and repeatability

Typical Applications

- Aerospace structural components

- Precision industrial equipment

- Medical and electronic housings

- Custom or low-volume aluminum parts

The primary limitation of CNC machining is higher per-unit cost, especially for large volumes or complex geometries that require long machining time.

Cast Aluminum vs Machined Aluminum: Key Differences

| Comparison Factor | Cast Aluminum | Machined Aluminum |

| Manufacturing method | Mold-based casting | CNC subtractive machining |

| Tooling cost | High (mold required) | None |

| Unit cost | Low for high volumes | Higher per part |

| Dimensional tolerance | Moderate | Very high |

| Mechanical strength | Lower, may vary | Higher and consistent |

| Surface finish | Fair to good | Excellent |

| Ideal production volume | Medium to large batches | Prototypes & small batches |

This comparison highlights why casting vs machining is not a one-size-fits-all decision.

Cost Comparison: Which Is More Economical?

When selecting cast aluminum versus machined aluminum, cost is usually the foremost consideration. Yet, it can be an error the other way around if only the per-part price is considered, as it will not indicate true cost. Lifespan of the product is considered in the total cost evaluation along with factors like tooling, production scale, secondary processing, scrap rate, and long-term scalability.

Cast Aluminum Cost Factors

1. Initial mold investment: The die casting process needs special steel molds, which are costly to make, thus involving high costs at the start. The part complexity, number of cavities, and projected tool life are all factors that determine the price of molds. This initial investment may be pretty high, but it is still a one-time cost that gradually becomes smaller as the production volume gets larger.

2. Alloy selection: The selection of casting alloys (for instance, A380, ADC12, or A356) is a factor that will affect the cost of materials, mechanical performance, and casting process efficiency. Also, some alloys provide better flow and surface finish, thus lowering defect rates and the need for post-processing.

3. Production volume: The cost of cast aluminum lowers as the production volume increases. After the mold is ready, the cycle times are short, labor input is negligible, and the unit costs decrease rapidly. Thus, die casting is the best choice for medium to high-volume manufacturing.

4. Secondary machining requirement: While die casting offers ready-to-use parts, often CNC machining will still be necessary for the precision of holes, threads, or sealing surfaces. The amount of this secondary machining has a direct impact on the final cost of the part.

In the case of massive production volumes, the die casting process is remarkably economical since the cost of tooling is spread over thousands or even millions of parts, leading to a very low cost per unit.

Machined Aluminum Cost Factors

- Raw material cost (billet aluminum): CNC machining is done starting from solid aluminum stock, for example, 6061 or 7075 billet. A big part of this material is taken away during machining, which increases the waste of material in comparison with casting.

- Machining time: Cost is directly proportional to the duration of the machining cycle; the longer the cycle, the more expensive it gets. The machining time and labor cost are impacted by high precision and complex designs, along with multi-axis operations.

- Tool wear and consumables: Cutting tools become dull and unusable sooner or later, especially when they are used for machining the most difficult of aluminum alloys. Hence, tool replacement and maintenance become part of the overall expense.

- Scrap material: CNC machining produces a lot of aluminum waste in the form of chips. The recycled scrap aluminum has still not reached the efficiency level of near-net-shape casting.

CNC machining is usually more economical for:

- Prototypes and pre-production samples

- Small to medium batch sizes

- Frequent design changes or engineering iterations

Strength, Tolerance, and Performance Differences

Components made from machined aluminum usually have higher and more uniform mechanical strength. Their production from wrought aluminum with a finely tuned grain structure and virtually no internal defects is the reason for this. The uniformity of these properties is of utmost importance for parts that are subjected to high loads or that are critical for safety.

In contrast, cast aluminum parts might exhibit some problems caused by the casting imperfections like:

- Porosity

- Internal voids

- Micro-defects or inclusions

The journey of contemporary die casting has been significant, and one of the factors that helped, among others, is the introduction of vacuum-assisted casting, alongside the improvements in mold designs. However, in situations dealing with high stress, fatigue loading, or strict safety measures, CNC-machined aluminum is still the option due to its material behavior predictability.

Tolerance Comparison

- Cast aluminum: ±0.1–0.3 mm (typical, depending on process)

- CNC machined aluminum: ±0.01–0.02 mm or tighter

Thus making CNC machining the technology of choice for precision interfaces, alignment features and sealing surfaces.

Application-Based Selection Guide

Automotive Industry

Cast aluminum components

- Gear housings

- Transmission cases

- Structural brackets

These parts benefit from complex shapes, integrated features, and cost efficiency at scale.

- Precision mounting surfaces

- Bearing seats

- Critical interfaces

Machining ensures tight tolerances and reliable assembly performance.

Aerospace Industry

The aerospace sector relies primarily on machined aluminum parts due to:

- High strength requirements

- Tight tolerance control

- Certification and traceability standards

Wrought aluminum alloys and CNC machining provide the consistency required for flight-critical components.

Industrial Equipment

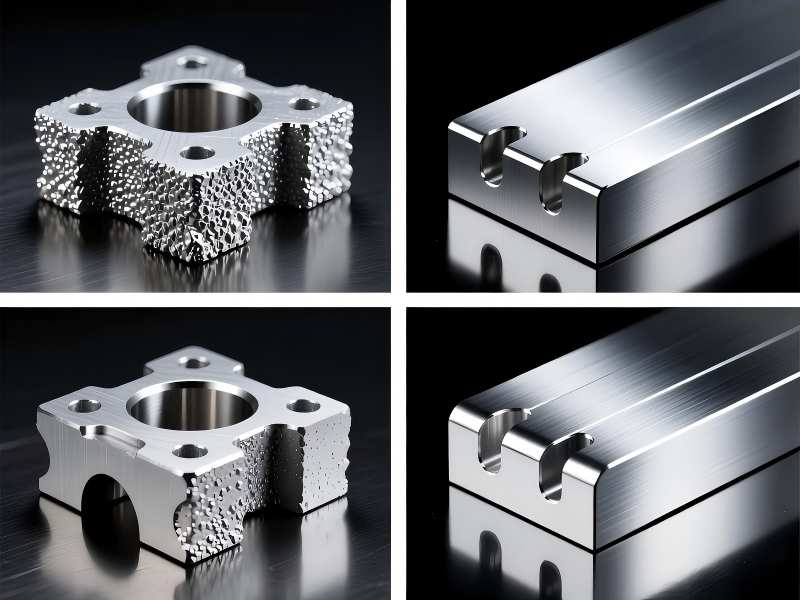

- Many industrial applications adopt a hybrid manufacturing approach:

- Cast aluminum for the main structural body

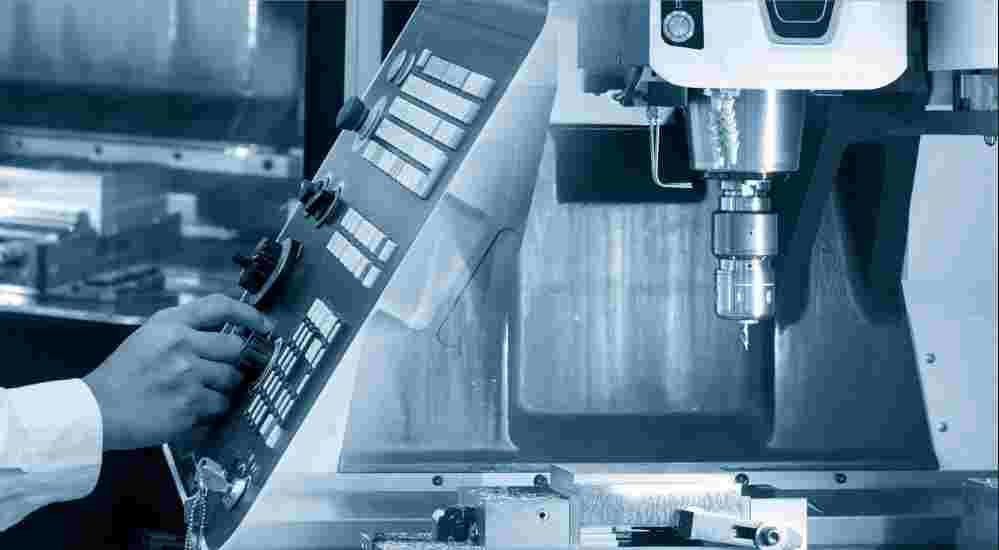

- CNC machining for precision features such as threads, bores, and mating surfaces

This approach balances cost efficiency with functional accuracy.

Die Casting + CNC Machining: The One-Stop Manufacturing Advantage

A manufacturing process that typically involves both casting and machining together into one main production workflow is the most efficient solution in modern manufacturing.

What Is a One-Stop Service?

A one-stop service for die casting and CNC machining fuses the following:

- Near-net-shape component manufacture through aluminum die casting

- CNC machining for the accurate dimensions and features needed

- Surface finishing, inspection, and ultimate quality control

Key Advantages for Buyers and Engineers

1. Cost Structure Optimized: Raw materials used in die casting are very little, and besides that, the machine makes the basic shape, so there is not much waste at all. The implementation of CNC is only done where precision is required, which leads to a reduction in the total manufacturing cost.

2. Shorter Lead Time: The use of a single supplier eliminates the time spent on vendor coordination. The communication between the casting and machining teams is faster, thus reducing logistics, re-handling, and outsourcing delays to a great extent.

3. Enhanced Dimensional Accuracy: The CNC finishing of critical holes, threads, sealing surfaces, and mounting interfaces leads to improved assembly accuracy and consistent part performance.

4. Greater Quality Control: A one-stop supplier uses common quality standards throughout the whole process. Due to the single point of responsibility, defect tracing, tolerance management, and inspection become more efficient.

5. Production That Can Be Scaled: The integrated model makes it possible to scale up from prototypes to mass production gradually while at the same time maintaining the same quality and supply stability for long-term programs.

This hybrid manufacturing has become very popular in automotive, EV, industrial automation, and energy equipment production.

How to Choose: Cast Aluminum or Machined Aluminum?

Prior to reaching a conclusion, reflect on these inquiries:

- What is the anticipated yearly output?

- How strict are the tolerance and surface finish requirements?

- Is the part a structural, functional, or aesthetic one?

- Does the design feature intricate internal geometries?

- Is a rapid time-to-market a decisive factor?

Quick Decision Guide

- Low volume + high precision → CNC machined aluminum

- High volume + complex geometry → Die casting

- High volume + precision features → Die casting + CNC machining

FAQ: Cast Aluminum vs Machined Aluminum

Q1: Which is stronger, cast aluminum or machined aluminum?

Machined aluminum is generally stronger and more consistent due to its wrought structure.

Q2: Is cast aluminum less expensive than CNC machining?

Yes, it is for medium to large production volumes.

Q3: Is it possible to CNC machine cast aluminum parts?

Definitely. This is a commonly practiced and suggested method.

Q4: Which method is better for prototypes?

CNC machining is usually the best option for prototypes.