There is a serious change happening in global manufacturing right now. Many companies are beginning to use service-based and outsourced manufacturing instead of spending a lot of money on new equipment, hiring new workers, and opening new factories. This flexibility allows companies to change and upgrade their products quickly without spending a lot of money on new capital. Because of these reasons, CNC machining services in China are now some of the fastest growing industries in global outsourcing. With great technical capabilities and strong supply chains ready to export products, China is viewed by many international companies as an essential extension of their production and engineering teams.

Why Global Outsourcing Is Accelerating

Outsourcing has grown very quickly – and it’s not by chance. It’s due to both economic and technological changes in society. More and more businesses are opting to buy services (OpEx) instead of investing in expensive assets (CapEx) as equipment (like CNC equipment) becomes more and more expensive and obsolete every 3-5 years. Outsourcing also facilitates flexible, smaller batch production, which is beneficial for research and development (R&D) teams, hardware startup companies, and any field designed for rapid iterations.

Key drivers include:

- Cost reduction and capital efficiency

- Access to external engineering and manufacturing expertise

- Lower production risk during product development

- Shorter time-to-market for new hardware

- Global supply chain diversification

Within this environment, companies increasingly rely on China CNC milling services to produce prototypes, functional components, and small-batch production runs.

Why Have CNC Manufacturing Services Moved Over to China?

Even though CNC machining services have just recently become popularized in China, because of its previous manufacturing and industrial specializations, China was able to integrate CNC machining services, which led to CNC outsourcing in China being a leader all around the globe.

China’s CNC outsourcing manufacturing environment is very complete and scalable, and there are very few areas in the world that are able to replicate it.

Some of the Key advantages of CNC machining service in China are:

- A completely integrated supply chain of Materials, heat treatment, anodizing, plating, grinding, and inspection service, all being in one area to decrease logistics time/costs

- Skilled workforce in machining, as there are thousands of factories available in 3, 4, and 5-axis CNC machining services. May produce at peak production in no time.

- Cost of machining is way more affordable in China because of economies of scale compared to more developed countries in the world, like the United States and Japan

- Export oriented manufacturing, which also has provable certifications like ISO 9001 or AS9100 for its quota of exports and achievements in the more complex and advanced industries.

- Customs processes and consolidation of multiple exports for one customer to make the shipment more efficient, which improves delivery and gives a tracking estimate to the customer.

There is good diversity and range for CNC machining services in China to support customers from the automotive, robotics, aerospace, electronics, and industrial equipment sectors.

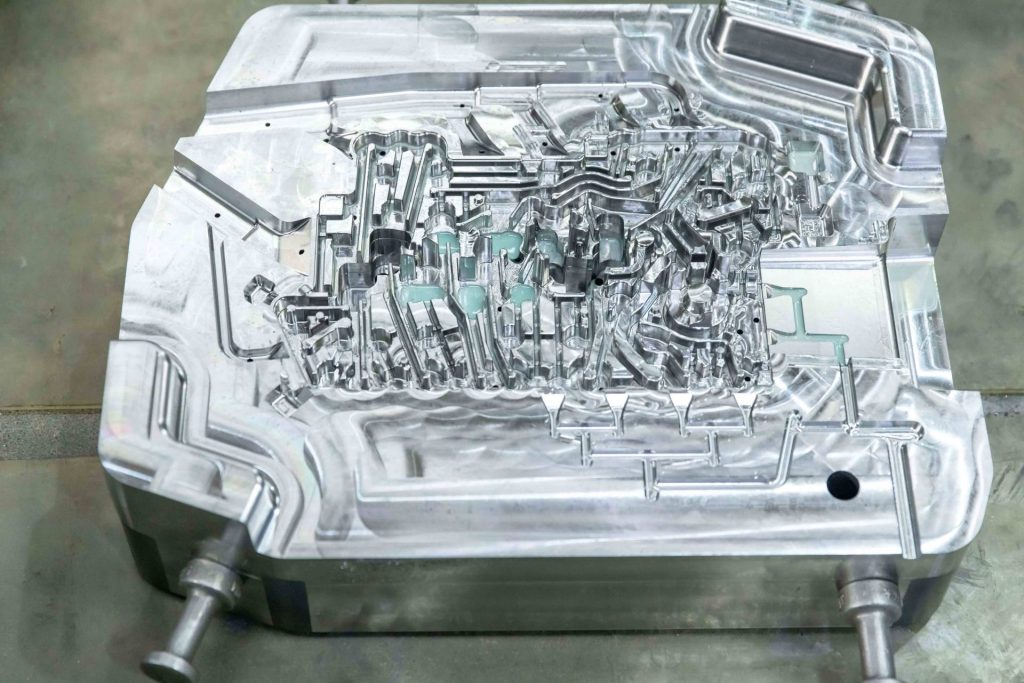

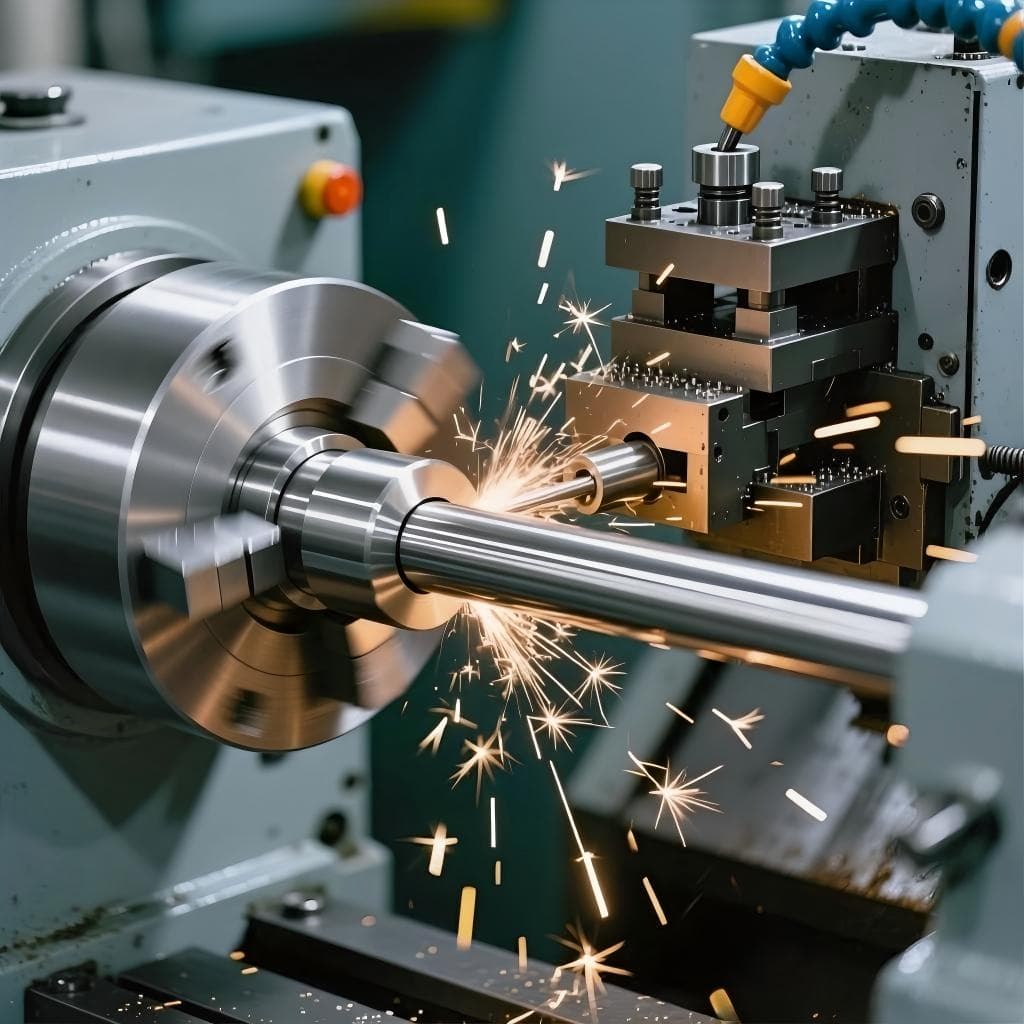

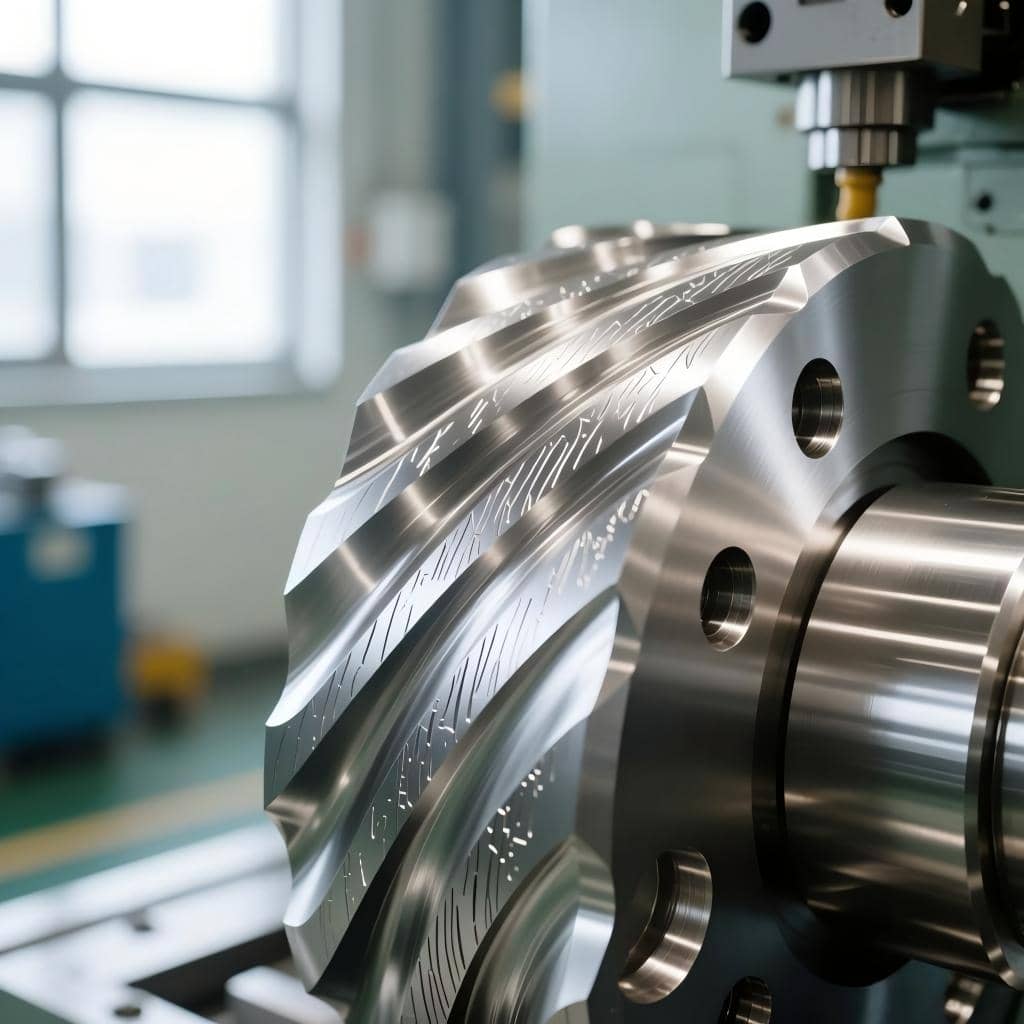

Technical Capabilities: From Simple Machining to High-Precision Manufacturing

China has just emerged as a competitor in the low-cost machine industry. Over the past decade, the improvement has quality of Chinese machine has seen improvement in equipment, software, and precision measuring subsystems.

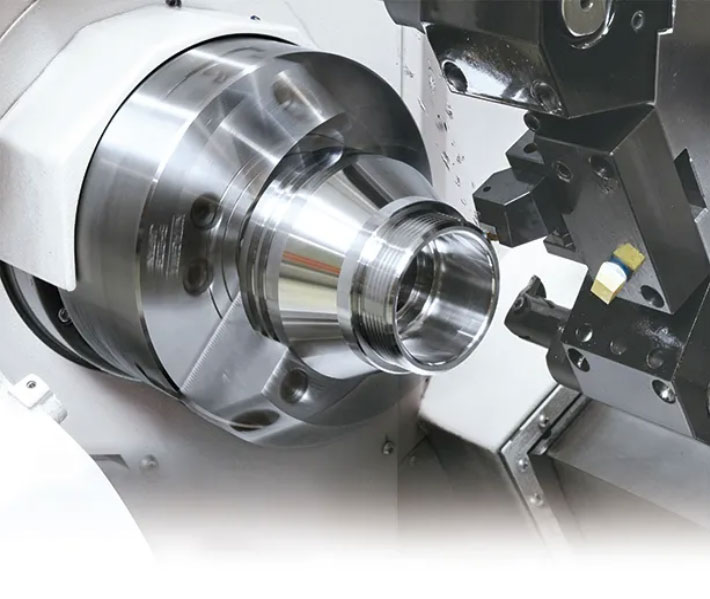

Modern CNC shops in China commonly provide:

- 5-axis machining for complex aerodynamic and medical components

- Multi-tasking turn-mill centers for one-setup machining

- High-precision machining for aluminum, stainless steel, titanium, and tool steel

- Automated robotic loading systems to support 24/7 production

- Advanced CAM programming and simulation

- CMM inspections, laser scanning, and full measurement reports

China CNC milling services have far greater consistency than ten years ago. Customers have the ability to obtain fast prototypes as well as production, where low tolerances are required.

The Demand of Service Based Manufacturing

The most recent trend in modern factories in China has been rebranding themselves from the traditional machining workshops to what the industry now calls “manufacturing service providers.” These establishments do not just provide bespoke machining services, but rather offer complete solutions.

Some of the services offered include:

- Initial DFM (Design for Manufacturability) optimization

- Material selection and engineering

- Some machining services, including CNC milling, turning, drilling, tapping, grinding, and EDM

- Finishing services, including anodizing, powder coating, plating, and heat treatment

- Assembly and subsequent packaging

- Quality assurance documentation and inspections

This service-based shifted business model has made CNC machining China exceedingly convenient for overseas teams and organizations that do not have local manufacturing partners, or that require production solutions that are extremely responsive.

Benefits of Cost, Speed, and Flexible Core Outsourcing

Performance improvements across multiple metrics are common with CNC machining service outsourcing in China.

The benefits received include:

- Lower production costs. Saving from 25%-50% is especially common with production orders and prototyping.

- Faster turnaround times. There are 3-7 day intervals from when a Chinese CNC supplier gets an order to when they have the prototype ready.

- Flexible order sizes. One-off prototype orders are common and from there production scales to mass orders of thousands of units.

- Risk in product development is reduced. CNC machines, operators, and programming engineers do not need to be acquired by the company.

- An array of materials and surface treatments is available. These include aluminum, steel, brass, titanium, plastics, carbon steel, and more.

Global companies choose China CNC milling for the same reasons: it is cost-effective. It also gives the engineers more opportunities to iterate on the hardware quickly.

Key Risks in Outsourcing—and How Chinese Suppliers Address Them

While outsourcing does provide new opportunities, new risks emerge, too. Top CNC machining service providers in China have adjusted their systems to deal with the most typical worries from global clients.

Typical concerns include:

- Quality consistency across batches

- Communication clarity

- IP protection

- Delivery reliability

- Supplier stability

Common solutions now implemented:

- CMM inspection, PPAP, FAI, and detailed inspection reports

- English-speaking project engineers

- NDA contracts and encrypted file uploads

- Backup production lines to prevent delays

- Strict material traceability and quality control systems

These improvements make CNC machining China a robust, dependable choice for long-term global production.

Which Companies Benefit Most from Outsourcing to China?

A wide range of industries rely on CNC machining services in China as part of their global supply chain strategy.

Typical users include:

- Hardware startups and R&D teams

- Robotics and automation companies

- Medical device manufacturers

- Aerospace component suppliers

- EV and automotive innovators

- Industrial equipment manufacturers

- Consumer electronics developers

All of these sectors depend on fast, flexible, precision CNC machining, making outsourcing to China particularly valuable.

FAQ: CNC Machining Service in China & Global Outsourcing

1. Why do companies choose CNC machining service in China instead of local manufacturing?

Many companies choose CNC machining service in China because of cost efficiency, fast service, machining technology, and great supply chains. China CNC manufacturers allow competitive outsourcing, rapid prototyping, small-batch production, and complex parts fabrication. In some regions, outsourcing is more economical and efficient than local fabrication.

2. Are China CNC milling services reliable for high-precision components?

Yes. Lots of China CNC milling services manufacturers have sophisticated 4-axis and 5-axis devices, multi-function turn-mill centers, and automation examination tools like CMM and laser scanning. These technologies enable high tolerances, consistent quality, and replicable accuracy appropriate for aerospace, medical, automotive, and robotics.

3. How fast can China CNC milling services deliver prototypes or production parts?

Lead times vary by project, but most china cnc milling services offer:

- Prototypes: 3–7 days

- Small batch: 7–12 days

- Mass production: 15–25 days

Fast delivery is one of China’s biggest advantages, thanks to its dense industrial clusters and efficient supply chain.

4. What materials can Chinese CNC machining companies handle?

Typical materials include:

- Aluminum (6061, 7075, 6082)

- Stainless steel (304, 316, 17-4PH)

- Carbon steel & tool steel

- Titanium alloys

- Brass & copper

- Engineering plastics (POM, ABS, PC, PTFE, Nylon)

This wide selection makes CNC machining service in China suitable for nearly any industry.

5. Are small orders or one-off prototypes accepted?

Absolutely. One key benefit of China CNC milling services is flexibility. Many suppliers accept:

- One-piece prototypes

- Custom R&D parts

- Small batch runs

- Engineering validation parts

This makes China an excellent production partner for startups and engineering teams.