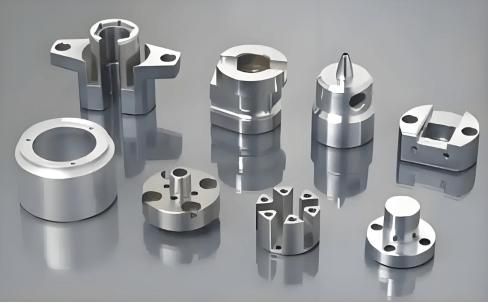

Materials We Offer

Check out our selection of quality materials for CNC machining, injection molding, sheet metal fabrication and 3D printing, for both prototyping and production stages.

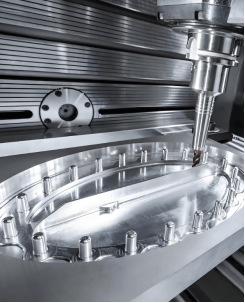

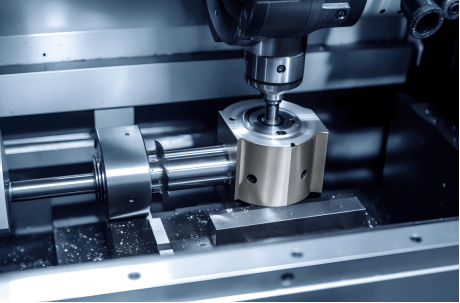

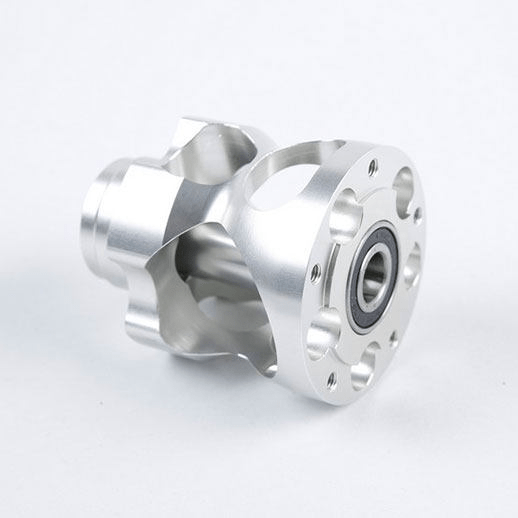

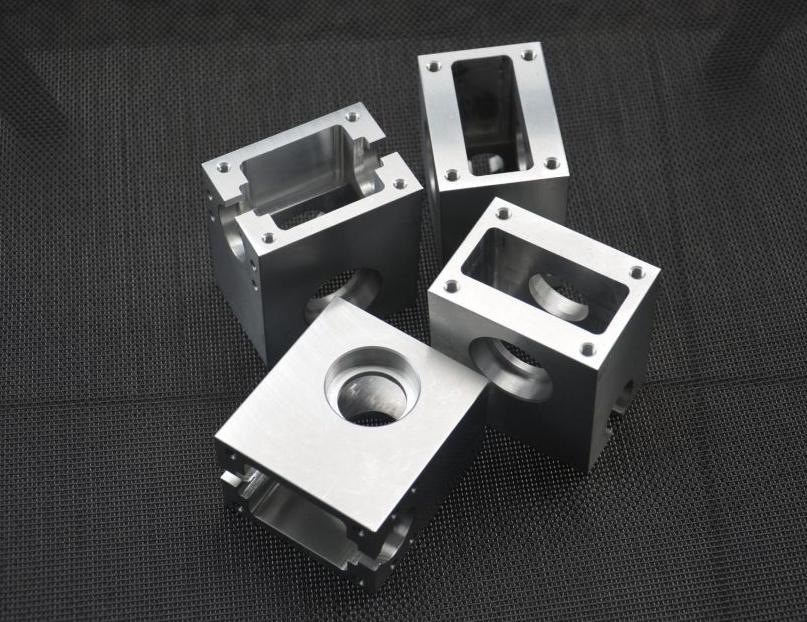

CNC Metals

Magnesium

Magnesium provides ultra-lightweight performance, shock absorption, good machinability, and strength-to-weight advantages. JTR offers CNC milling and turning for magnesium components. It is used in aircraft housings, automotive gearbox casings, camera frames, and electronic enclosures for weight reduction.

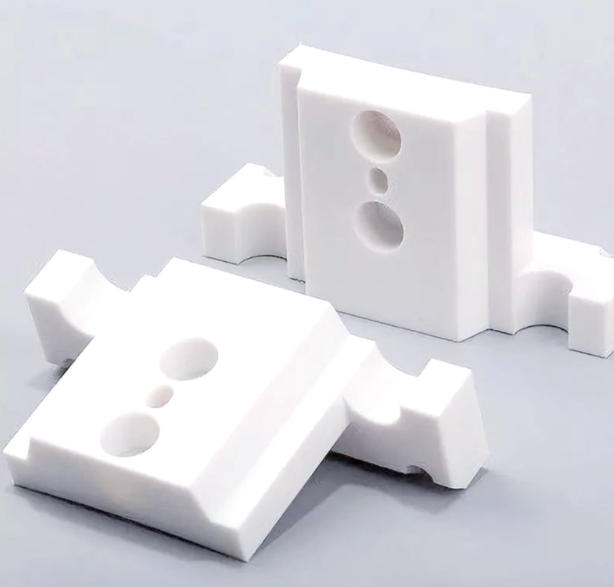

CNC Machining Plastic

PMMA

PMMA provides clarity, UV resistance, and a smooth surface finish. CNC PMMA parts are widely used for display panels, light covers, automotive lamps, and optical prototypes.

POM

POM delivers low friction, stiffness, and dimensional stability. CNC POM parts are often used for gears, bearings, bushings, and precision machinery components requiring wear resistance.

PE

PE is lightweight, flexible, and resistant to chemicals. CNC PE parts are used for containers, seals, insulating components, and medical or packaging prototypes.

PEEK

PEEK offers high strength, chemical resistance, and heat tolerance. CNC PEEK parts are often used in aerospace connectors, medical implants, pump components, and semiconductor equipment.

PP

Polypropylene features fatigue resistance, lightweight, and chemical stability. CNC PP parts are widely applied in living hinges, automotive components, food packaging, and laboratory equipment.

PTFE(Teglon)

PTFE provides chemical resistance, non-stick properties, and high temperature stability. CNC PTFE parts are commonly used for gaskets, seals, insulators, and sliding components in chemical or electrical systems.

PS

Polystyrene is rigid, low-cost, and easy to machine. CNC PS parts are often used for housings, disposable instruments, packaging inserts, and transparent prototype models.

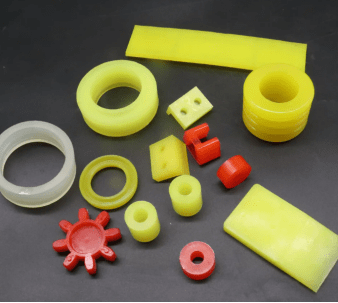

Injection Molding Plastics

ABS

ABS combines toughness, impact resistance, and good surface finish. Widely used in automotive dashboards, electronic housings, toys, and appliance parts, it balances strength and cost for mass production.

PMMA

PMMA, or acrylic, provides high optical clarity, UV resistance, and scratch resistance. It is ideal for lighting covers, display panels, automotive lamps, and optical parts.

POM

POM (acetal) delivers low friction, high stiffness, and dimensional stability. Injection-molded POM parts include gears, bearings, clips, and precision components in automotive and machinery industries.

PE

Polyethylene (PE) is lightweight, chemical-resistant, and flexible. Typical applications include containers, packaging parts, medical devices, and liners for industrial equipment.

PEEK

PEEK provides high strength, chemical resistance, and heat stability. It is used for medical implants, aerospace components, pump parts, and semiconductor equipment requiring premium performance.

PP

Polypropylene (PP) offers chemical resistance, fatigue durability, and low cost. It is used in automotive bumpers, living hinges, packaging containers, and household products.

PTFE(Teglon)

PTFE offers unmatched chemical resistance, non-stick properties, and thermal stability. Injection-molded PTFE is used in seals, gaskets, insulators, and chemical processing parts.

PBT

PBT combines electrical insulation, toughness, and heat resistance. Injection Molding PBT parts are commonly found in automotive connectors, appliance housings, electronic components, and industrial equipment.

Stamping Material

Aluminum

Aluminum offers lightweight strength, corrosion resistance, and excellent formability. Stamping aluminum parts are often used for automotive body panels, heat shields, electronic housings, and appliance components requiring both durability and weight reduction.

Copper

Copper features outstanding electrical and thermal conductivity, plus good ductility. Stamping copper parts are widely used in heat exchangers, electrical contacts, busbars, and connectors in power and electronic industries.

Steel

Steel delivers high strength, cost efficiency, and durability. Stamping steel parts are frequently found in brackets, enclosures, chassis, and structural reinforcements across automotive, construction, and machinery sectors.

Carbon steel

Carbon steel combines strength, toughness, and cost-effectiveness. Stamping carbon steel parts are often used for gears, fasteners, mounting brackets, and industrial machine components that demand high wear resistance.

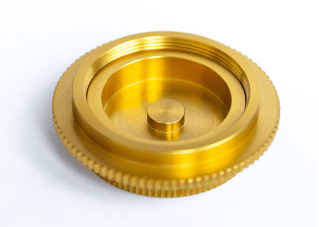

Forging Material

Aluminum

Aluminum provides lightweight strength, corrosion resistance, and good toughness. Forging aluminum parts are often used for aerospace brackets, automotive suspension components, bicycle frames, and lightweight structural elements requiring durability and precision.

Brass

Brass features easy formability, wear resistance, and an attractive finish. Forging brass parts are commonly used for valves, gears, decorative fittings, and precision connectors in plumbing and electrical applications.

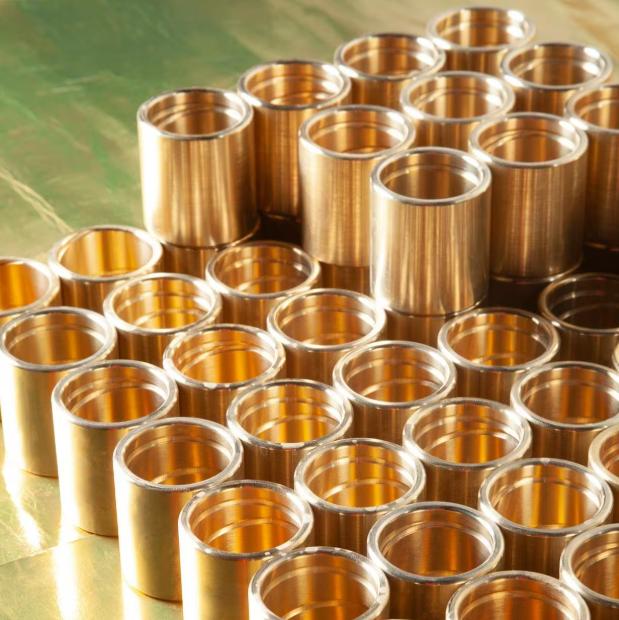

Bronze

Bronze delivers wear resistance, fatigue strength, and seawater corrosion protection. Forging bronze parts are ideal for bearings, bushings, ship propellers, and heavy-duty industrial components requiring long service life.

Stainless steel

Stainless steel combines corrosion resistance, strength, and heat resistance. Forging stainless steel parts are widely used in medical tools, food processing equipment, aerospace fasteners, and high-performance automotive components.

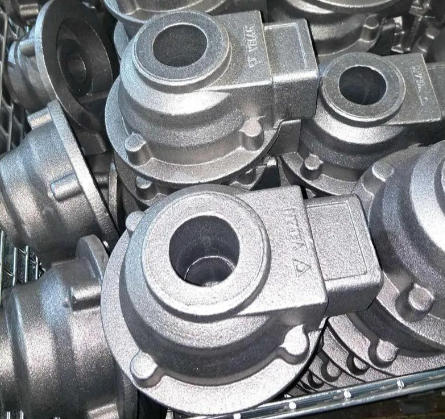

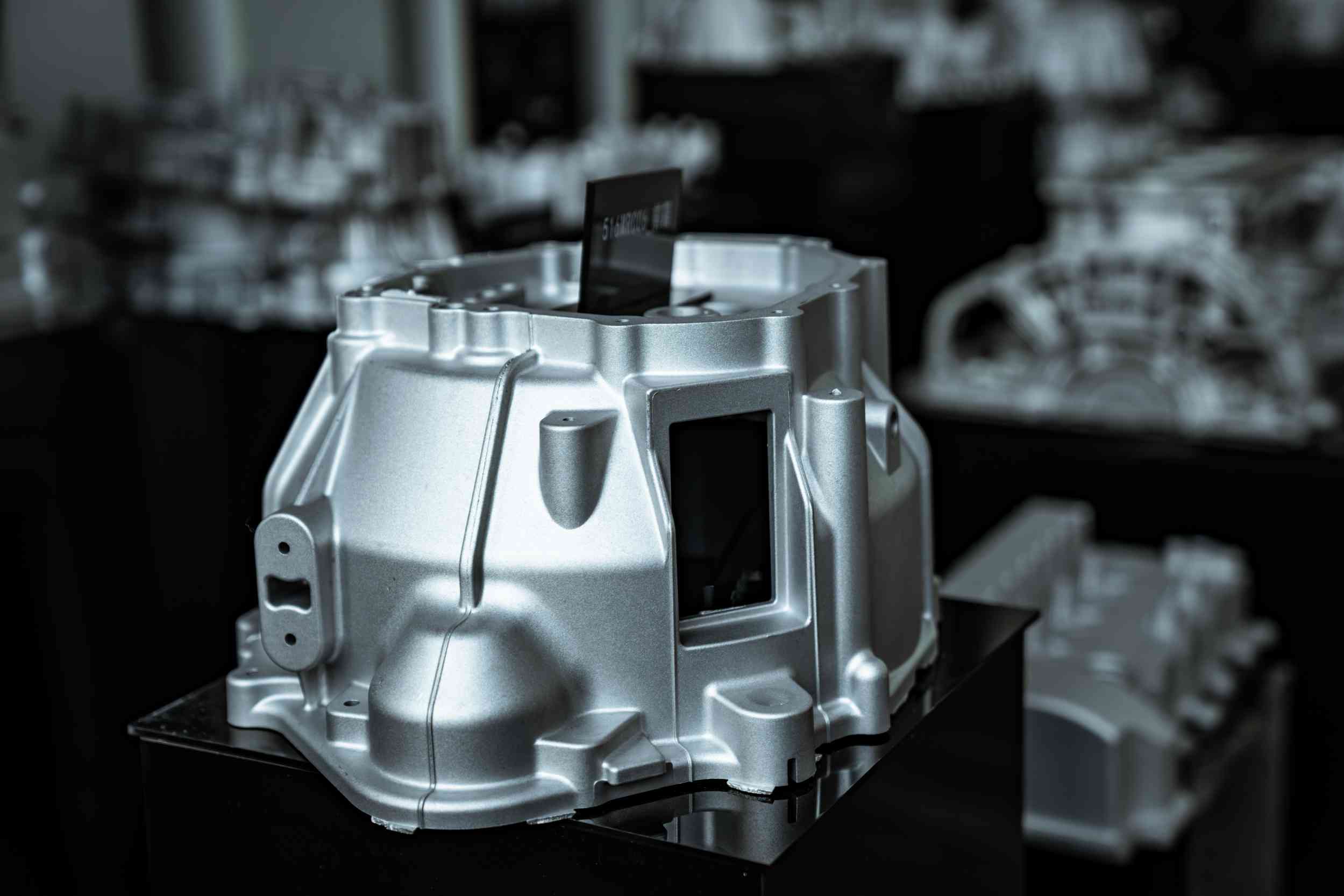

Casting Material

Iron

Iron offers excellent compressive strength, wear resistance, and cost efficiency. Casting iron parts are often used for engine blocks, pipes, pump housings, and heavy machinery components in automotive and industrial applications.

Aluminum

Aluminum features lightweight performance, corrosion resistance, and good thermal conductivity. Casting aluminum parts are widely used for automotive engine housings, aerospace brackets, electronic enclosures, and consumer appliance components.

Copper

Copper delivers excellent electrical and thermal conductivity with corrosion resistance. Casting copper parts are typically used for electrical connectors, plumbing fixtures, heat exchangers, and decorative components.

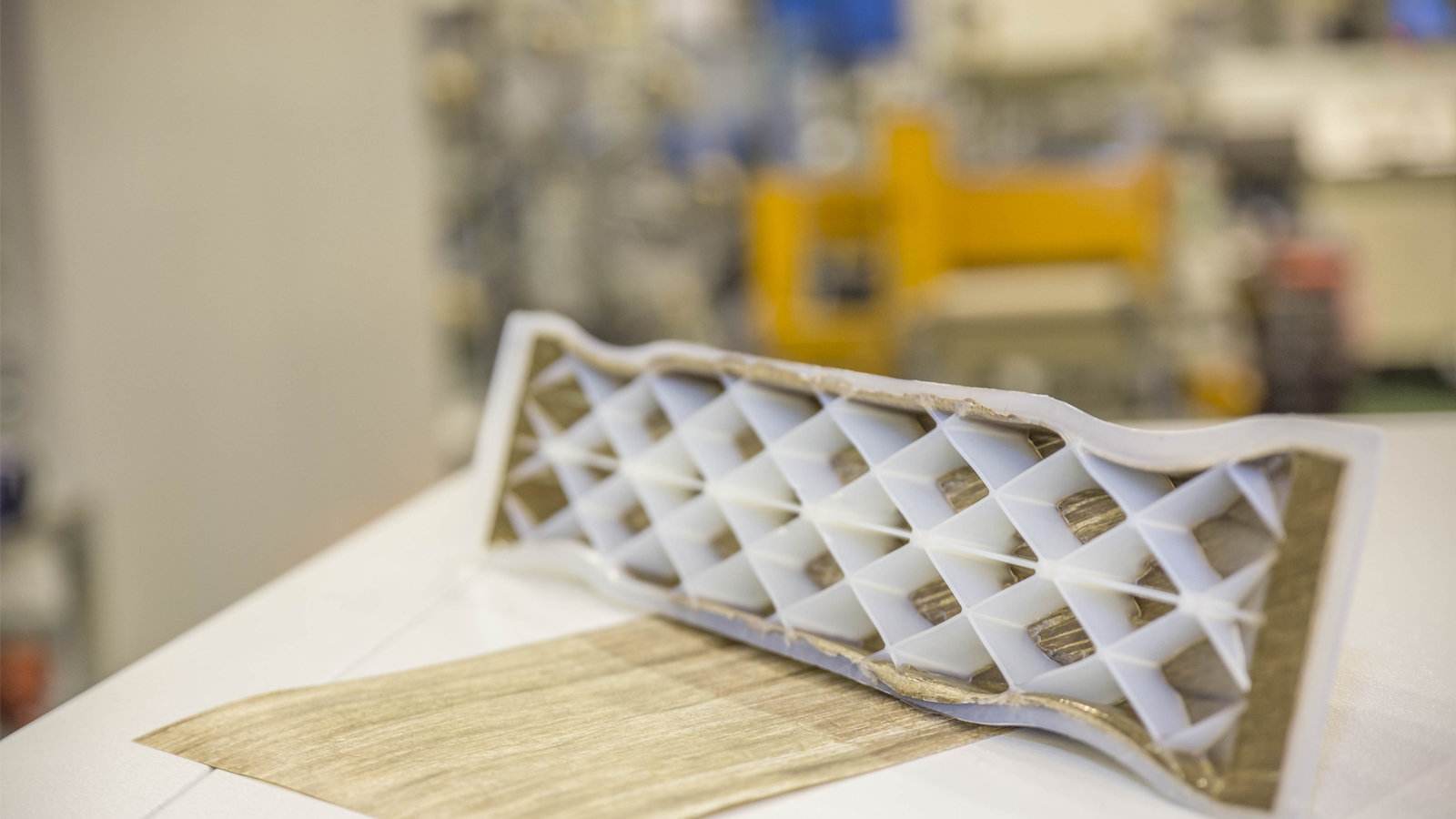

3D Printing Material

ABS

ABS offers toughness, impact resistance, and easy processing. 3D Printed ABS parts are often used for functional prototypes, automotive interior components, electronic housings, and consumer product models requiring durability and low cost.

Aluminum

Aluminum features lightweight strength, corrosion resistance, and thermal conductivity. 3D Printed Aluminum parts are commonly applied in aerospace brackets, heat exchangers, automotive engine components, and consumer electronics housings for high-performance solutions.

Stainless Steel

Stainless steel delivers corrosion resistance, strength, and heat resistance. 3D Printed Stainless Steel parts are often used for medical instruments, tooling, aerospace components, and industrial machinery requiring durability and precision.