Metal Stamping Service

Metal stamping, a method of sheet metal fabrication, is a cold-forming process, it makes great use of dies and stamping presses in forming sheet metal into various custom shapes. It adopts specialized tooling which involves the stroke of the punch that brings conformational change to the metal sheet. Through the application of adequate force to the metal sheet by the punch, a metal stamper can do many machining to the sheet, such as cutting or forming.

At JTR, we can make metal stamping very easy and fast, to make you a comfortable order, we provide free design advice, and fast delivery service, and there are many other services available, such as CNC milling, and CNC turning, 3D Printing. We try our best to become a one-stop shop.

Our Manufacturing Capabilities

Custom Manufacturing

Design your desired products, provide free advice on your project design, and prepare the die set in the shortest time to get your project started.

Intricate Fabrication

We have a professional team on metal stamping to work on intricate manufacturing issues, so we can ensure the product are all in a precise state.

Fast Manufacturing

With the most advanced equipment, we are able to make each project to be finished in the fastest time. While the detailed time will depend on how complicated your project is.

Types of Metal Stamping

Progressive Die Stamping

Progressive Die Stamping is a superb method for long-run production, it adopts a sequence of stamping stations. Metal coil fed into a reciprocating stamping press with progressive stamping dies. And the die runs with the press, the metal moves horizontally along till to the last station. And the precisely formed part will be separated there. Among the producing line, each step is a different cut, bend, or punching operation on the metal, so the metal sheet can be gradually turned into the desired end-product shape and design. It is a fast process with a limited amount of wasted material.

Mechanical Presses

Mechanical presses consist of two main parts of a die set, which are the lower shoe(as well as the die shoe), and the upper shoe. They are both machined to be parallel with a few thousandths of an inch. The upper die shoe sometimes is provided with a shank, where the whole tool is clamped to the ram of the press. Because of their heavy weight, large dies will not be mounted this way. There are various sizes of the equipment, from 20 tons up to 6000 tons. And strokes range from 5 to 500 mm (0.2 to 20 inches), and the speed of it is 20 to 1500 strokes per minute.

Mechanical presses are well suited for high-speed blanking, shallow drawing, and especially for making precision parts.

Transfer Die Stamping

Transfer die stamping is alike progressive die stamping in the working principle, while the part is separated early on in the process, the produced product will be transferred from one stamping station to the next by another mechanical transport system. This process is usually used on larger parts that might need to be transferred to different processes.

Hydraulic Presses

The principle of hydraulic presses is similar to mechanical presses, while it varies in its force tonnage from 20 to 10,000 tons. The strokes can vary from 10 mm to 800 mm (0.4 to 32 in). Hydraulic presses can deliver any point of the stroke at full power, variable tonnage with overload protection, and alterable stroke and speed. Hydraulic presses are commonly used for deep-drawing, and compound dies action (blanking, forming and coining, etc). At low speed while with high tonnage, it forms parts in force rather than displacement.

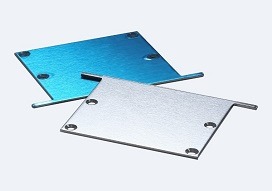

Metal Stamping Design

Metal stamping is a complicated process that can involve a great number of metal forming processes, such as blanking, punching, bending, piercing, etc. A perfect project stamping design will depend on the customer’s needs for the product.

| Methods | Functions |

| Punching | In punching operations, a scrap piece of material is removed as the punch enters the die, effectively leaving a hole in the workpiece. |

| Blanking | removes a workpiece from the primary material, making that removed component the desired workpiece or blank. |

| Embossing | creating either a raised or recessed design in sheet metal, by pressing the raw blank against a die that contains the desired shape, or bypassing the material blank through a roller die. |

| Coning | This action causes the punch tip to penetrate the metal and results in accurate, repeatable bends. |

| Bending | The bending process for metal results in a plastic deformation that stresses above the yield point but below the tensile strength. |

| Flanging | a process of introducing a flare or flange onto a metal workpiece through the use of dies, presses, or specialized flanging machinery. |

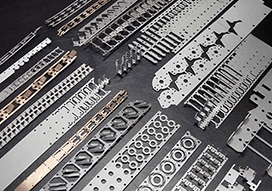

Sample Display

Hardware Parts

The most used in hardware processing refers to the mold for steel/non-ferrous metal and other plates at room temperature, which is formed into a specified shape by the pressure required for processing by the press.

Including some electronic devices, auto parts, decorative materials, and so on. The stamping parts we usually refer to are generally referred to cold stamping parts. For example, if you want to turn an iron plate into a fast food plate, you must first design a set of molds. The working surface of the mold in the shape of the plate. Press the iron plate with a die, and it becomes the plate you want. This is cold stamping, which is directly stamping the hardware material with a die.

Automotive Parts

Auto stamping parts are the units that make up the whole car and the stamping parts that serve the car. The processing of stamping parts of auto parts is a production technology of product parts with a certain shape, size, and performance by means of the power of conventional or special stamping equipment so that the sheet is directly subjected to deformation force in the mold and deformed. Sheet material, mold, and equipment are the three elements of stamping processing.

Materials For Custom Metal Stamping Service

Tolerance of Metal Stamping

The tolerances shown are economically for hard tooling exceptions.

| Features | Tolerance |

| Hole Diameter | ±0.005″ |

| Bend Radi | ±0.100″ |

| Outer Dimension | ±0.005″ |

| Holes within pattern | ±0.005″ |

| Cut Features to Bend | ±0.010″ |

| Angles | ±1 degree |

| Gauge Material | ±0.002″ |

Why Choose Us?

- More Experiences

JTR has specialized in precision metal stamping for decades. We have a team of experts to ensure that your stampings are not only of the finest quality, but we are also free to provide advice on your project design, and make sure our customers get a quick delivery time and competitive prices.

- More Options and More Possibilities

Combined with our various selection of materials, we can meet the needs of customers covering many industries. We are able to handle virtually any volume, large as well as small, even for the most intricate components. All of our manufacturing are subject to strict quality assurance processes, as demonstrated by our ISO9001:2008 and TS16949 quality system certification.

Try JTR Out Now In Just A Few Steps

Upload your project designs to us, we will make you perfect plan feedback.

As long as we received your confirmation, your project will get started.

Your custom machined parts will be delivered right to your doorstep.

Get ready to get an instant order? Fill up the following chart to contact us now!