In the last 10 years, many industries around the world have begun changing rapidly due to the digital revolution and AI-enabled automation and intelligent systems. In the turning and milling of precision components of aerospace, robotics, medical, automotive, energy, and consumer electronics, CNC systems are still the cornerstone of all manufacturing systems. With the increase in globalization, the market has been demanding higher precision, greater speed, and more customization for CNC milling and turning components. CNC turning and CNC milling services have been rapidly adopting digital technologies to increase efficiency and remain competitive.

The transition to smart CNC systems is more than simply changing the equipment. It’s the integration of systems to rethink the entire CNC machining services business from workflows, servicers and finally the entire value chain. Digital automation is adding services to custom cnc milling and custom cnc turning so they can more rapidly customize to highly complex designs at low production quantities.

Part 1. How Digitalization Is Changing CNC Milling and Turning Workflows

1. Cloud Manufacturing and Real-Time Data Monitoring

Today’s CNC workshops are more and more able to sync to cloud platforms where machine data is recorded and analyzed. Sensors embedded within CNC milling and turning centers document the cutting forces, spindle loads, vibrations, and temperatures, and which tools are getting worn. When uploaded to the cloud, data enables:

- Continuous monitoring of machine health and production statuses.

- Autotuning of cutting parameters to maintain optimal performance.

- Cloud dashboards that allow engineers or managers to supervise remotely.

- Strategic process optimizations from historical data.

The integration of cloud computing into CNC milling operations enables informed decision-making and downtime reduction. CNC turning operations see similar benefits as downtime is reduced and consistency and traceability improve. In custom manufacturing, data transparency is key in building and maintaining customer trust as it allows customers to see lead times and quality metrics and track order progress.

2. Digital Twin Technology for Process Simulation

The ability to create precise virtual replicas of physical machines and their integrated processes, called digital twin technology, has been revolutionizing CNC machining. Now engineers can simulate entire milling and turning operations before a cutting tool even touches the material to visualize toolpaths, assess possible collisions, and predict machining errors.

Using digital twins reduces the need for trial-and-error in the following applications in CNC milling:

– Thin-wall structures

– High-hardness metals

– Free-form surfaces

– Multi-axis toolpaths

Custom cnc turning sees the same benefits provided by digital twins when trying to predict the formation of chips, the load on tooling, and the surface finish. In today’s small-batch manufacturing, the simulation of digital twins reduces material loss, improves the first-part-correct rate, and reduces setup time, all of which are highly relevant.

Part 2. Smart Technology Improving Efficiency within Milling and Turning

1. Adaptive Machining and Toolpath Optimisation

One of the most important parts of CNC machining is artificial intelligence. In real time, AI evaluates cutting parameters and adjusts the feed rate, spindle speed, and tool angle. This capability of adaptive machining brings the following advantages:

- Improvement of machining efficiency by 30 – 50%

- Tool wear is lower and tool life is longer

- The same surface quality is maintained, even when machine parameters change

- When machining custom parts, it is possible to achieve a high level of repeatability and accuracy

Especially in custom cnc milling, diverse machining tactics can be employed to gain the most efficiency out of such advanced AI in the market today. In custom cnc turning, roughing, finishing, and threading operations can be optimised by AI through accurate cutting force predictions and appropriate feed patterns and routing.

2. Autonomous Workstations and Efficient Scheduling

Standalone CNC machining devices are being integrated into robotic and automated material handling subcontracted units. These units operate seamless in a smart scheduling system that automates and optimizes the allocation of production activities based on:

- Tool Set Availability

- Machine Workload

- Material Availability

- Due Date Reminders

Such systems improve the CNC milling service and CNC turning service responsiveness in more complex and varying job orders on urgent requests that are typical of custom processing. Automated loading systems and robotic arms, as well as pallet changers, are the reason more productivity is achieved without new personnel in night shifts.

3. AI Predictive Maintenance and Sensor Integration

Traditional maintenance is reactive; the machine is repaired after a failure. Maintenance becomes predictive on digitalization, as it relies on algorithms to pinpoint when a machine is likely to fail based on the data from the machine’s sensors. In CNC machining, it becomes necessary to avoid expensive failures.

- Predictive maintenance assists in improving:

- Reliability of milling and turning machines

- Stability of production schedules

- Lifecycle of spindles, bearings and motors

High machine uptime allows the custom cnc turning and custom cnc milling providers to improve delivery and quality that are more stable.

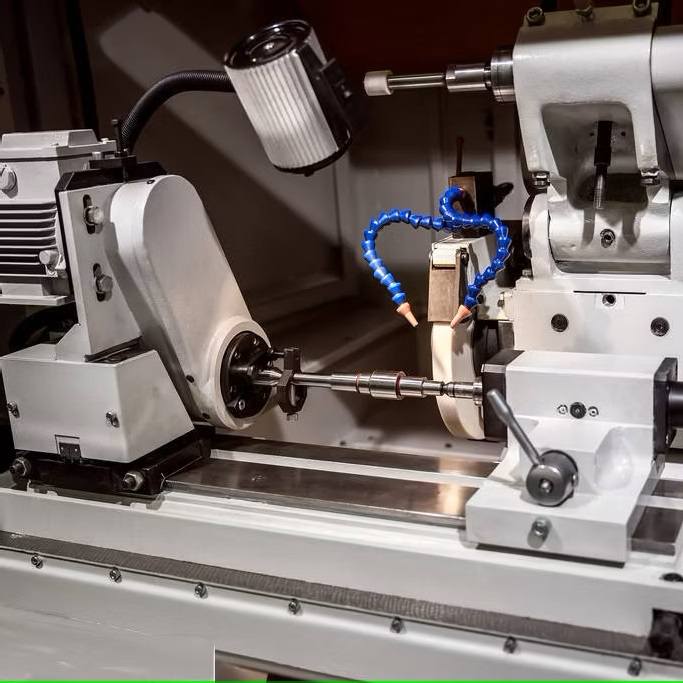

Part 3: The Digital Manufacturing Technology Evolution: Multi-Axis and Hybrid Technologies

1. The Development of Five-Axis Milling and Hybrid Machining Centers

In today’s digital machining environment, five-axis CNC milling machines and multifunction turning-milling centers are indispensable. They consolidate numerous machining operations—including milling, turning, drilling, tapping, and grinding—into a single machine setup.

This multifunction milling technology enhances efficiency in the following ways:

- Higher Accuracy: This is attributed to the requirement of fewer machine setups.

- Capability to Efficiently Process Complex Geometries: The machine’s ability to improve machining operations on intricate designs is unrivaled.

- Truly Advanced Machining of Complex Curved Geometries: This means that the machine can deliver on geometry that has tighter curvature along with greater changes in contour.

- Increased Accuracy and Efficiency in the Production of: This technology performs with unparalleled excellence in machining operations carried out in the aerospace, medical implant, robotic componentry, and automotive prototype engineering.

With the ability to measure and monitor complex geometries and the use of artificial intelligence in machine assistive technology, the potential of increasing productivity and precision is limitless, which strengthens the competitiveness of CNC milling service and CNC turning service providers.

2. Uses in Advanced Tech/Specialized Fields

CNC Digital Machining Technology has become more advanced and is now considered a standard requirement in a few industries where there is no room for error. This includes:

- Aerospace – turbine blades, structural brackets, actuator housings

- Medical – orthopedic implants, dental tools, components of surgical equipment

- Robotics – end-effectors, joints, housings of precision gears

- Electronics – aluminum and copper components with micro precision

These industries are also the ones that need to use custom cnc milling and custom cnc turning more, since standard components do not meet the requirements. As more industries start to design more complex components, the need for advanced CNC machining technology becomes more necessary.

Part 4. Digital Service Models: Forming a New CNC Business Ecosystem

1. Quoting Online and Working Alongside Customers

Digitisation is doing a transformation of how parts are machined as well as how customers interact CNC service providers. New-age service provides instant quotations online, checks manufacturability automatically, and tracks orders in real time.

For the service of CNC milling and CNC turning, the system’s online provides:

- Responding to customer inquiries happens at a greater speed.

- Predictions of costs are more accurate.

- Communication is enhanced between engineers and customers.

Customers are able to upload 3D models and, as part of the collaborative engineering, DFM comments are given. Cost improvements and greater efficiencies are gained in custom cnc milling and custom cnc turning, where part features are complex and require time to be analysed.

2. Digitalisation and High-Mix, Low-Volume Production

The production of an entire item in bulk and at a rapid pace is no longer possible. The global production sector is now focused on flexible, smaller units, as there is a rapid pace due to fast iterations of products and personalised needs in the market. With the help of automated scheduling, cloud-connected systems, and sophisticated CAM, CNC workshops are able to streamline the management of distinct orders.

Assisted digitalisation is helpful for:

- Startups working on prototypes

- Research and development departments are working on a new mechanical design

- Aerospace and Medical companies that need certified and customised parts

Custom CNC turning and CNC milling do their best in an environment where ample flexibility and customisation are offered, rather than quantity.

3. Traceability and Quality Assurance

Digitalisation allows for complete traceability from raw materials of manufactured parts to completion. Manufacturing parameters, inspection results, machine logs, and tool usage are all digitally archived, and the result is a significant improvement in:

- Quality control

- Diagnostic problem solving

- Compliance

- Regulatory

- Client relations

Industries where safety is essential and a priority, including medical manufacturing and aerospace, have come to view digital traceability as a fundamental requirement, leaving CNC service providers that are digitally ready much more competitive.

Part 5. Future Outlook: Toward Fully Intelligent CNC Manufacturing

As we advance in digital tech, the remote future and the next decade of CNC milling and turning will hinge on the integration of more AI, IoT, robotics, and the cloud together. Over the next 10 years, the future trends will be:

- CNC machining cells will be completely autonomous and operational 24/7

- Tool paths will auto-optimise themselves in real-time

- CNC manufacturing will seamlessly integrate additive with subtractive

- Digital twin machining operations will be cloud-based and universal in engineering

- Cloud manufacturing with elastic distribution will be universal

In these conditions, custom CNC milling, and custom CNC turning, will be in high demand to supply ultra-modern and custom high quality components with precision, extreme repeatability, and ever faster lead times. The companies that master digital tech in CNC machining will dominate the future of more intelligent industrial manufacturing.

Conclusion

Intelligent CNC machining and digitalization are in the process of changing the entire landscape of the CNC machining industry. Technologies like AI Toolpaths, real-time data milling, and automated multi-axis machine cells are leveling up the CNC turning and milling services to more efficient and flexible offerings. And for the industries that require high precision and flexible machining services, custom CNC machining will be an unmitigated success.

Today’s workshops and CNC turning and milling factories that are willing to invest in digital tech will be tomorrow’s leaders in global manufacturing.