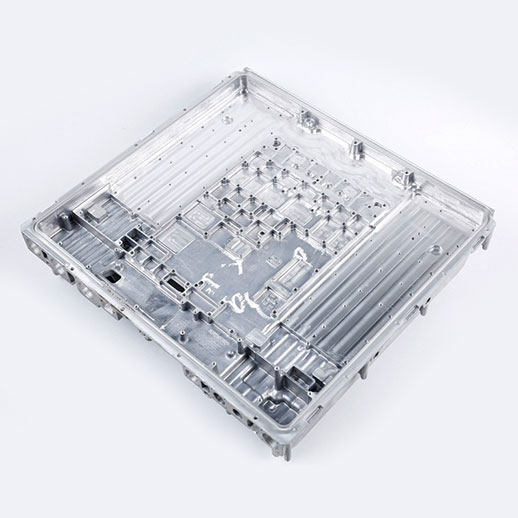

Aluminum CNC Machining ADC12 Parts

- Size: 499.5*358*87.1(mm)

- Main Material: ADC12

- Treatment: None

- CNC machining process: die casting → shot blasting → passivation → CNC milling → CNC drilling → cleaning and packaging

- Application fields: Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc.

Description

Definition of Aluminum CNC Machining

The machined surface shape of the CNC milling machine is generally composed of straight lines, arcs, or other curves. Ordinary milling machine operators according to the requirements of the drawing. Constantly changing the relative position between the tool and the workpiece, and then coordinating with the selected milling cutter speed, the tool can cut the workpiece, and various shapes of workpieces can be processed.

Advantages of Aluminum CNC Machining

- Parts have strong adaptability and flexibility and can process parts with particularly complex contours or difficult to control dimensions, such as mold parts, shell parts, etc.

- Can process parts that cannot be processed by ordinary machine tools or are difficult to process, such as complex curved parts described by mathematical models and three-dimensional space surface parts;

- It can process parts that need to be processed in multiple processes after one clamping and positioning.

- High machining accuracy, stable and reliable machining quality.

Our CNC Milling Capabilities

- Material Aluminum: 5052 /6061/ 6063 / 2017 / 7075 / etc

- Surface Finishing: Anodizing, Bead Blasting, Hard Coat Anodizing, Heat-treating, Induction Heat Treating, Laser Etching, Pad Printing, Painting, Parkerizing, Plating, Polishing. Powder Coating, Precious Metal Plating

- Process Drawing & Samples – Mould making – Die casting – Deburring – Drilling and threading – CNC Machining – Polishing – Surface treatment – Assembly – Quality inspection – Packing – Shipping

- Tolerance: +/-0.018mm

- Equipment: Vertical Machining Center, Vertical Drilling Center, 4-Axis Machining Center, Turning Machine, Drilling Machine, Sawing Machine, Hydraulic Press, Air Leak Tester, CMM

- Preferred formats: JPEG, PDF, PNG, CAD, IGS, UG, Solidworks

- Loading port: Chongqing

- Delivery time: 20-30 days after receiving orders, usually based on customers’ PO QTY

- Note: Above item is only for your reference, not for sales; we only produce custom parts per customer prints

- Applications: Automotive, Automation, Test Systems, Sensors, Medical, Sports, Consumer, Home Appliances, Electronics, Pumps, Computers, Power and Energy, Construction, Printing, Food, Textile Machinery, Optics, Lighting, Safety and Security, AOI, SMT equipment, etc.