CNC Machining Service

JTR provides you with a reliable one-stop CNC machining service, which provides rapid prototyping/end-use part production in a variety of materials, and related machining services to small, medium, and large-sized parts.

CNC Machining Processes

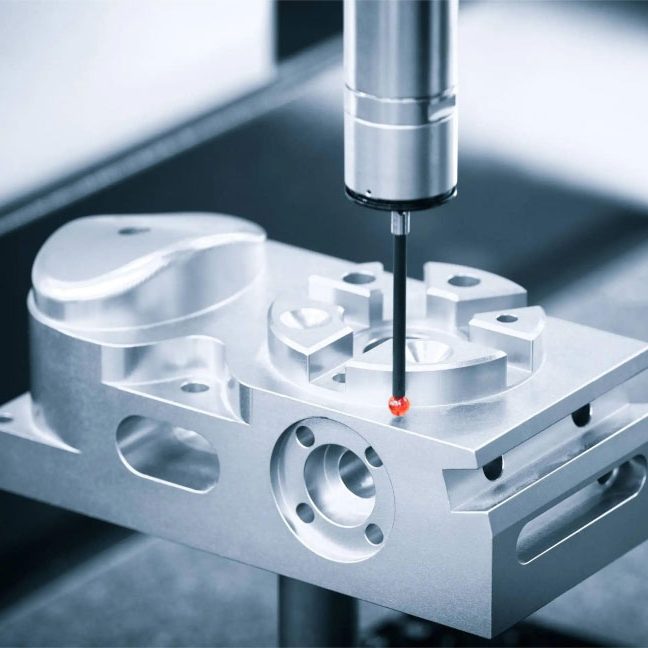

As CNC machining China service supplier, JTR provides high-quality rapid prototyping and mass manufacturing services, including CNC machining, rapid tooling and injection molding, sheet metal prototyping, die casting, 3D printing, and so on. We provide manufacturing solutions that realize your design within a few hours, we have more than 70 precision CNC processing equipment of various types to ensure the best quality of products.

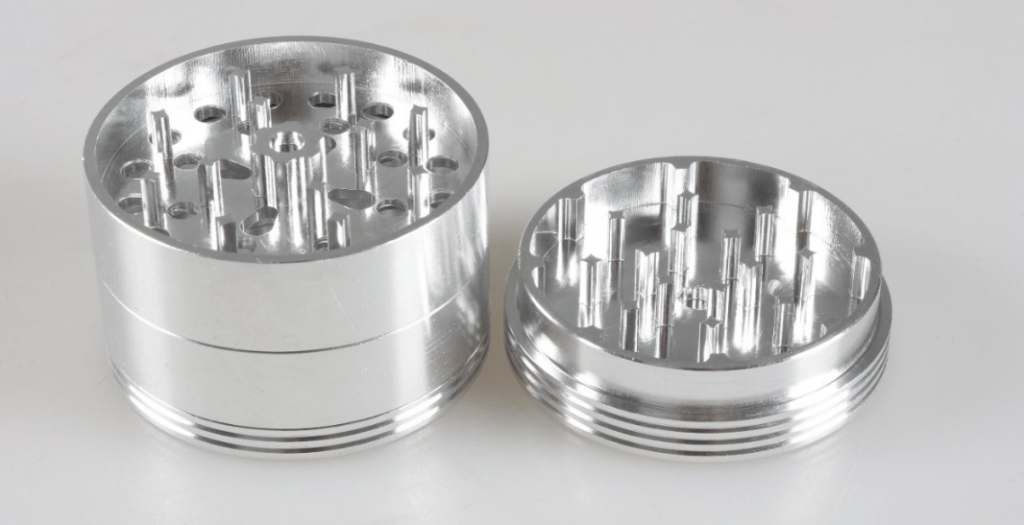

Our CNC Milling uses 3-axis milling and 5-axis indexed milling to rapidly cut a choice of more than 30 engineering-grade thermoplastics and metals into complex shapes and precision components.

As one of the subtractive manufacturing processes, milling removes material from bulk by using tools to cut/drill a workpiece. CNC Milling is capable of producing parts with high accuracy at a high speed.

CNC Turning Service

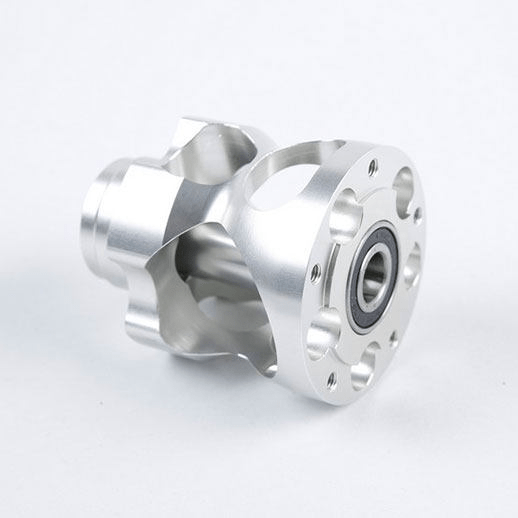

Our CNC Turning uses a lathe to create detailed functional prototypes and end-use parts with cylindrical features. It removes material from bulk by rotating the workpiece.

CNC Turning is great for the processing of cylindrical parts, capable of producing high-quality parts cost-effectively.

- CNC Milling and Turning: A composite machining technique that the production of complex curved or profiled parts through the design of multiple tasks through the collaboration of simultaneous rotation of the tool and the workpiece.

- CNC Drilling: A common technique at JTR, with it we give various CNC difficulties more operational possibilities. For the fabrication of either small or large series of parts, CNC drilling allows us to drill holes up to 7 cm at least. And it is also suitable for metals, alloys and polymers.

Our CNC Machining Capabilities

As one of the leading precision CNC machining services suppliers in China, JTR has strong capabilities to serve your needs of CNC machined parts, from rapid prototyping to precision parts and tooling machining, to end-use parts.

Custom Design

We machine your parts as designed, we also offer perfect modification suggestions to optimize the production process and reduce costs. You can select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

High Efficiency

Low Tolerance

Wide Materials Selection

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

Diversified Machining

Small and large quantities, perfect for the production of 1-10,000 parts; Metals and plastics; Simple machined parts, and complex CNC machined parts.

Global Services

Our parts have been exported to Europe, the USA, Australia, South America, the Middle East, Southeast Asia, etc.

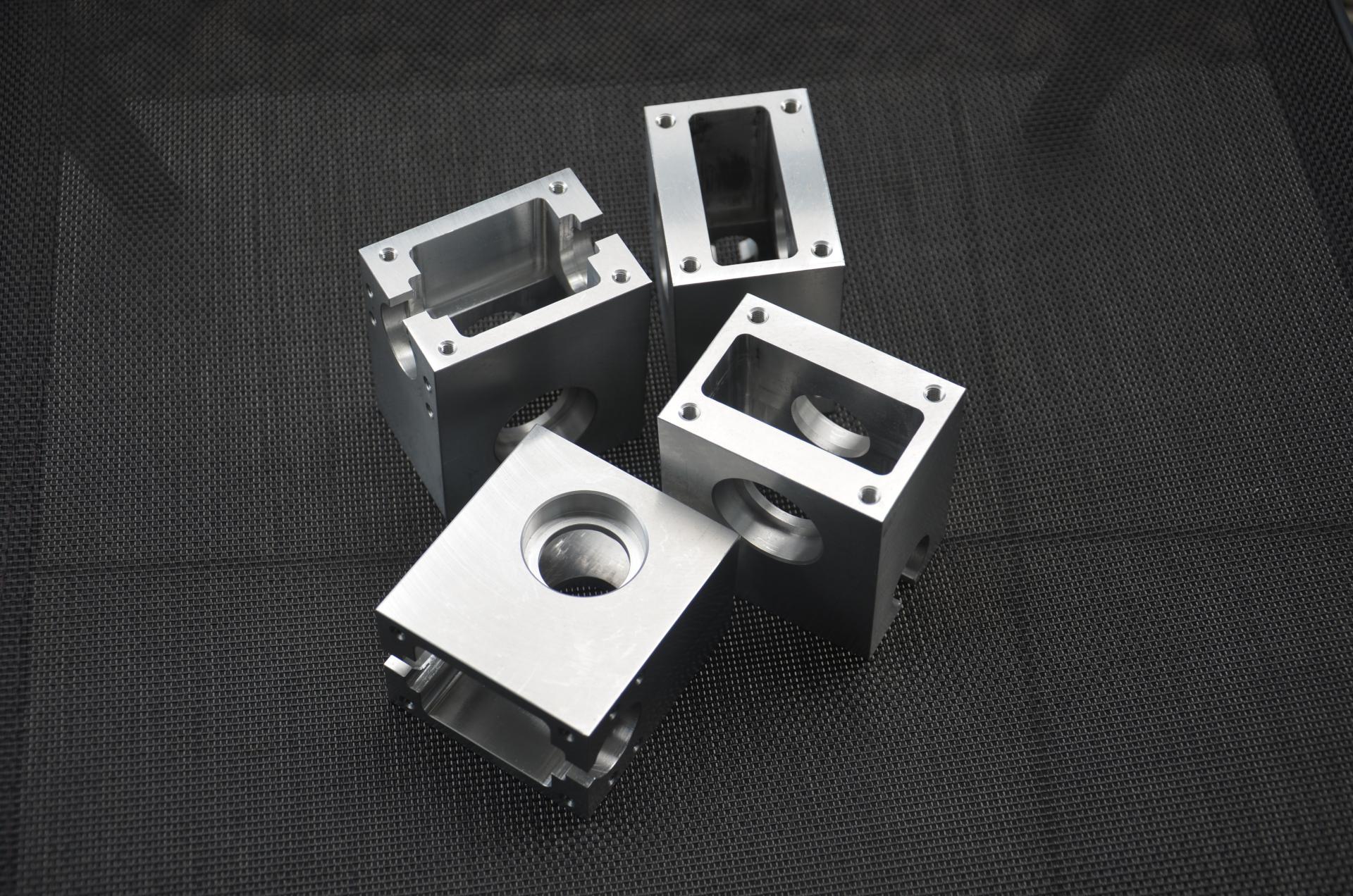

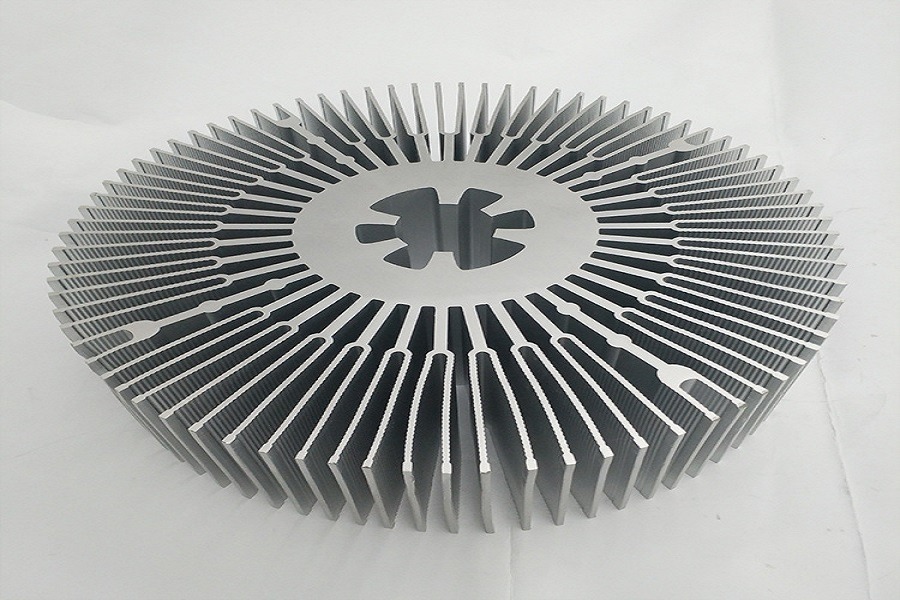

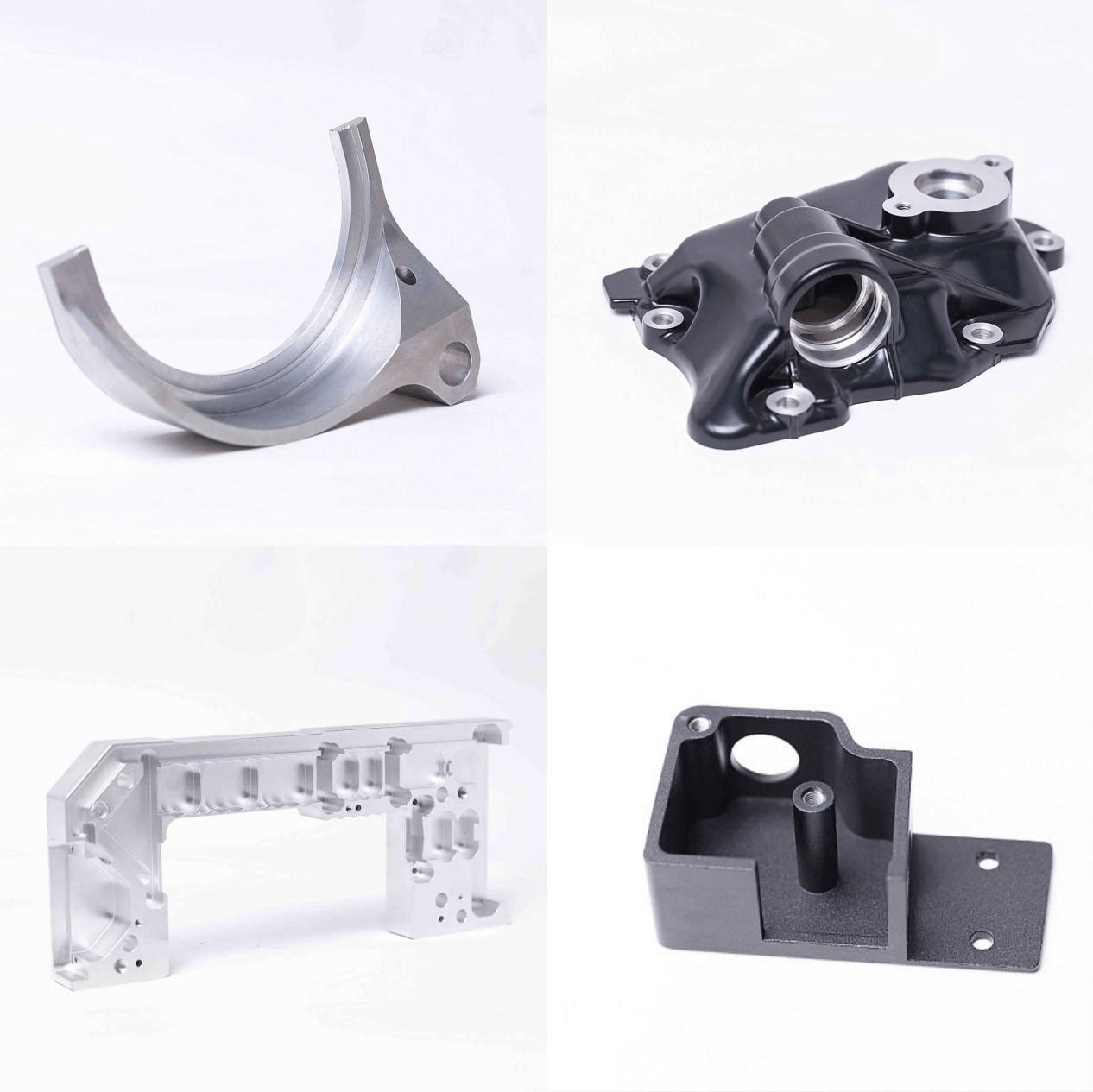

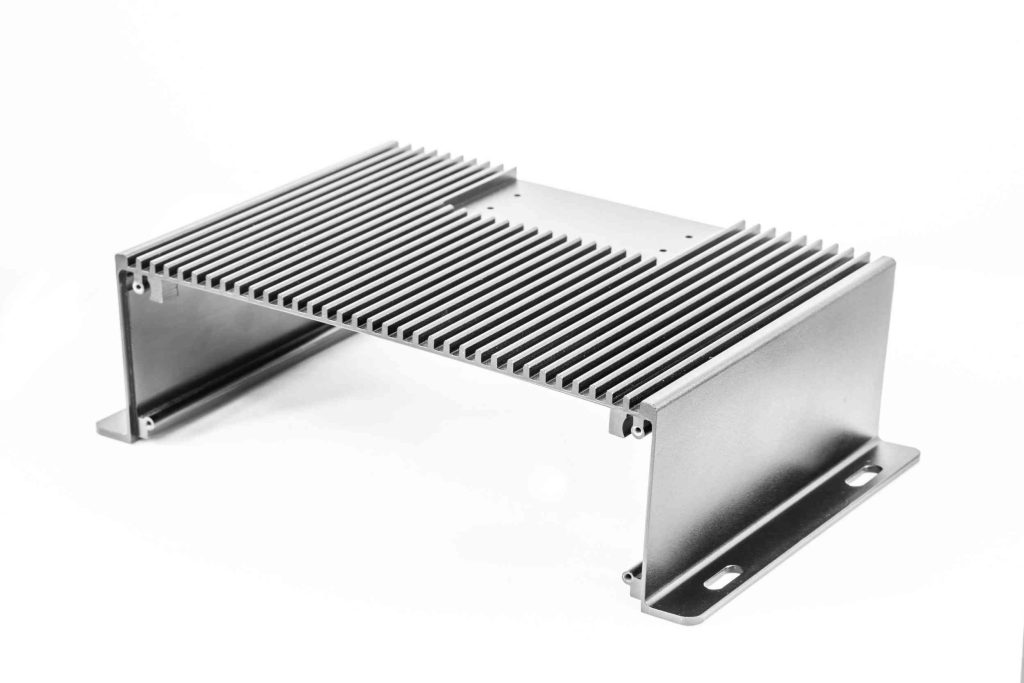

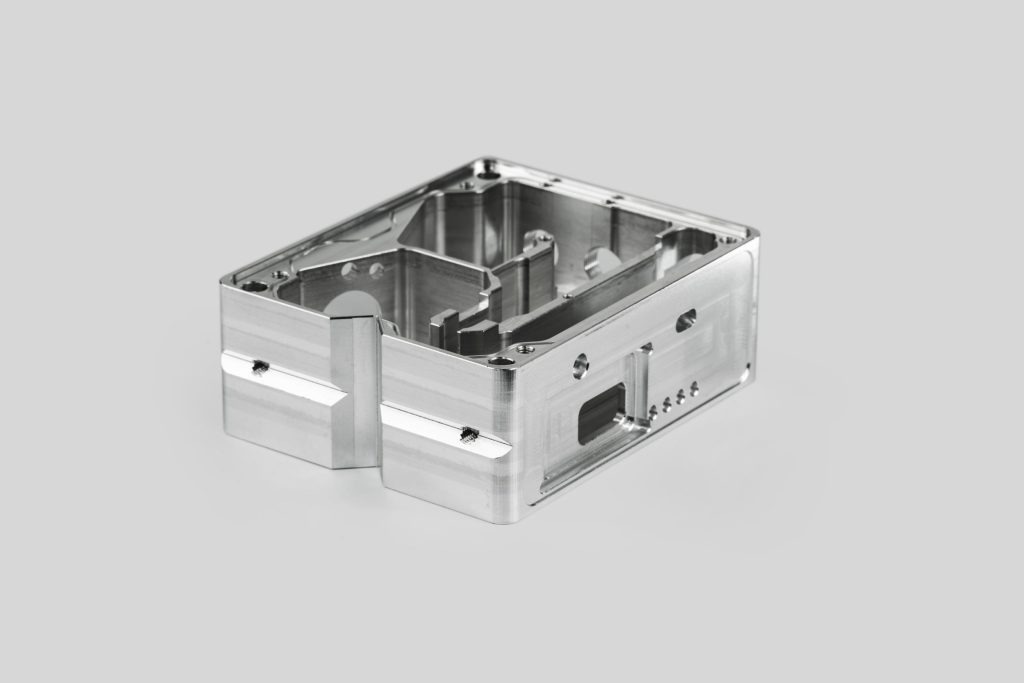

CNC Machining Products

We process rapid prototyping and produce low-volume production orders for customers in multiple industries. We are good at using CNC machining technologies such as CNC Milling, CNC Turning, Wire EDM to help customers realize the ideas in their minds.

Our CNC machining supports the manufacture of parts and custom products for aerospace, automotive, defense, electronics, industrial automation, machinery, manufacturing, medical devices, oil and gas, and robotics.

Materials for CNC Machining Parts

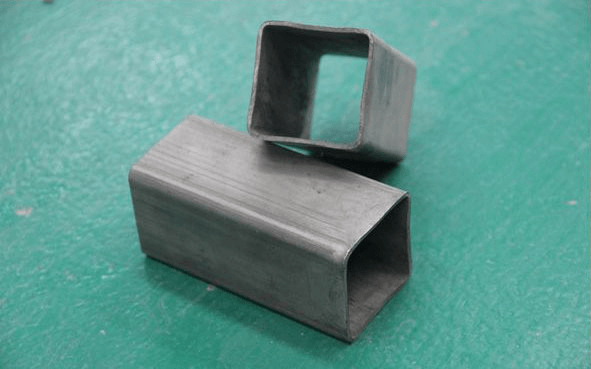

Steel is one of the most widely used metalworking materials. Steel is used in a wide variety of fields, from parts manufacturing to building materials.

At JTR, we provide CNC machining services for more than 10 types of steel.

Mild steel / Carbon steel / 4140 / 4340 / Q235 / Q345B / 20# / 45#, etc.

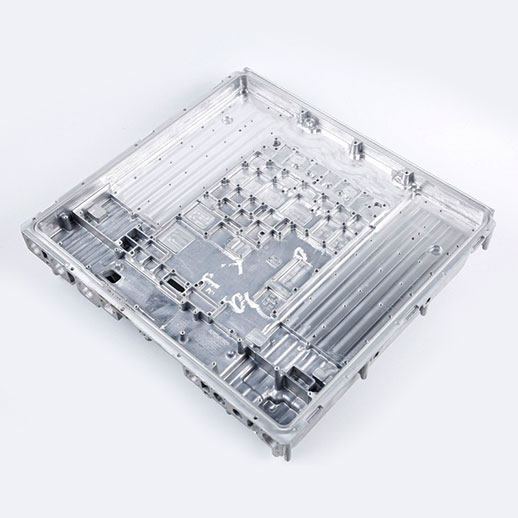

Aluminum alloy precision parts and products are popular for their light and delicate appearance, and the CNC machining of aluminum can perfectly reflect the physical properties and fineness of the parts. Therefore, CNC machining has become the first choice for aluminum prototyping and small batch production.

At JTR, we can provide CNC machining of most aluminum.

Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc.

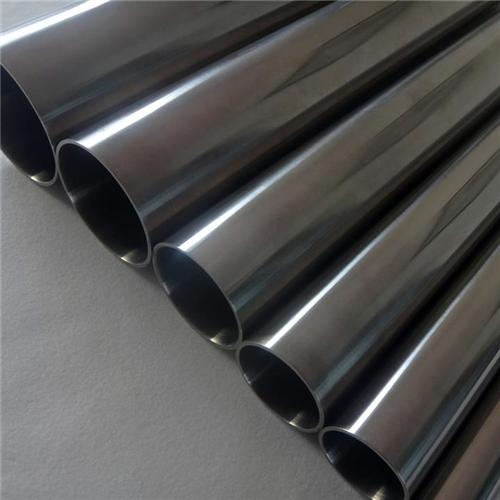

CNC Machining Stainless Steel Parts

Stainless steel is one of the most used materials. It is called the hardest alloy. In the machinery industry, CNC machining is the mainstream method of stainless steel machining.

At JTR, we can provide CNC machining services for more than 10 types of stainless steel.

SS201 / SS301 / SS303 / SS304 / SS316 / SS416, etc.

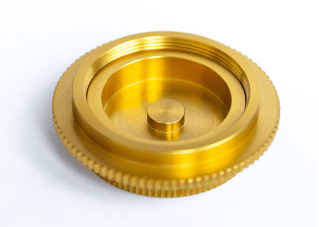

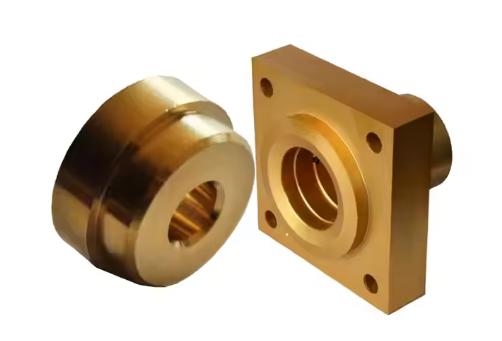

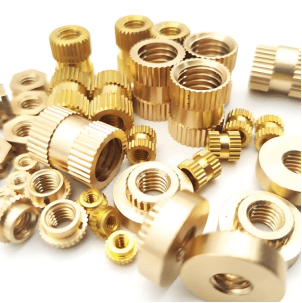

CNC Machining Brass/Copper Parts

The parts or products obtained by CNC machining brass/copper can not only reflect the characteristics and advantages of brass/copper but also amplify the advantages of brass/copper. JTR provides CNC machining services for most types of brass/copper on the market. Use CNC Turning, CNC Milling, and more to turn your part or product into what you have in mind.

Brass HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90, etc.

C11000 / C12000 / C12000 / C360, etc.

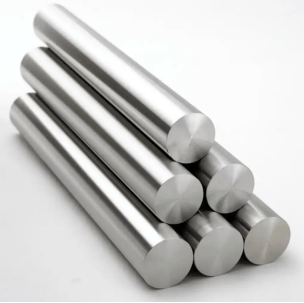

Titanium materials are materials with certain shapes, sizes, and performances made of titanium ingots and titanium alloy metals through certain pressure processing, and are also called titanium processed materials. CNC machining is a good choice for machining titanium material into titanium parts, which can reveal the details of titanium parts.

Our titanium machining capabilities include Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc.

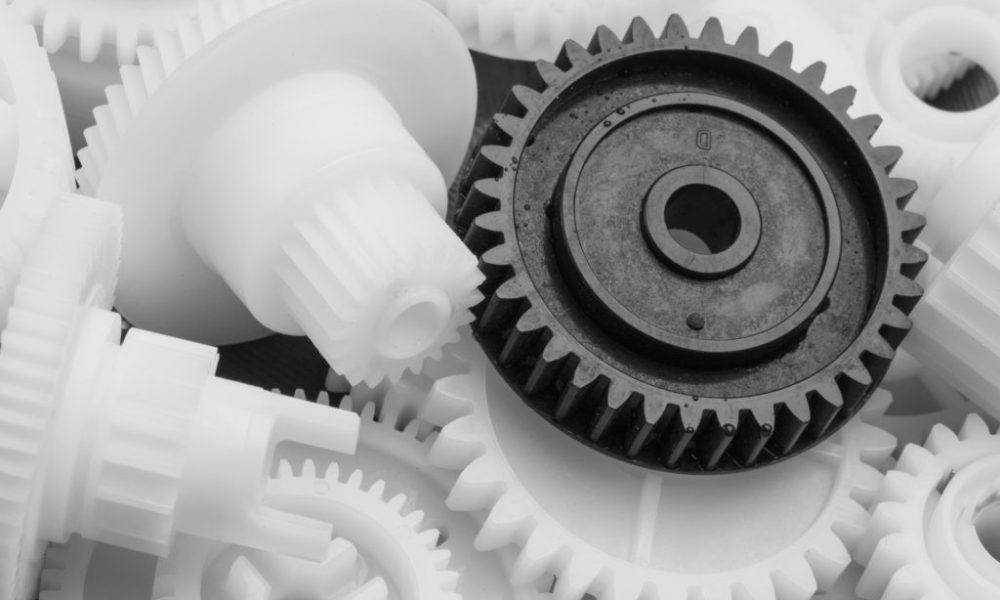

As a new type of CNC machining material, plastics appear in various industries, and their value is slowly being discovered by people. At JTR, we turn plastics into parts or products through a variety of methods, including CNC machining, CNC turning, CNC milling, and more.

Our CNC machining capabilities include ABS, Nylon, Polycarbonate, and many other materials.

Other Materials for CNC Machining

In addition to the above conventional materials, we also provide CNC machining services for other materials.

Inconel, Invar, Magnesium, etc.

Surface Finishes for CNC Machining

As Machined

Painting

Sandblasting

Shotblasting

Wire Drawing

Passivation

Logos printing

Anodizing

Chrome Plating

Zinc Plating

Mirror-like protection for aesthetics, anti-rust and other functions.

Tolerances for CNC Machining

| Process | Tolerance(mm) |

| CNC Milling | ±0.005(metal) / ±0.05(plastic) |

| CNC Turning | ±0.005(metal) / ±0.05(plastic) |

| CNC Grinding | ±0.005(metal) / ±0.05(plastic) |

| The Best Surface Finishing | Ra0.1 |

We have specified our standard dimensional tolerance of ±0.005mm(0.0002in) for CNC manufactured parts. While there’s no certainty to achieve an exact even tolerance on our lathes, routers, axis mills, and 5-axis mills. If you are in need of a specific tolerance, please notify us, we will make a perfect plan for you.

Thinner sheet metal in the process of CNC machining might need CNC jigs being used, if that would happen, our engineering and designing team will confer with you to provide you with the best plan.

Size Limitation For CNC Machining

| CNC Milling | CNC Turning | |

| Max Diameter | 3500mm (138in) | 2500mm (99in) |

| Min Diameter | 0.1mm (0.003in) | 0.1mm (0.003in) |

CNC machines are able to manufacture products of a huge variety of complications and sizes. Yet, limitations also do exist in the machining, there are some limitations caused by the size, so we specified a size limitation table of CNC machining for you to refer to. It is necessary for both designers and engineers to know these limitations in order to design. So please read the table before contacting us.

The larger part can be reviewed and specially processed, get a quote for us to see!

Lowest CNC Service Price

4 factors made our lowest price

| CNC Time | The numerical control rate is estimated to be 60%. Thus we can shorten the complishment time and labor cost at the best level. |

| CNC Materials | We are able to provide you with many kinds of of materials at your favorable price. |

| CNC Equipment | 70 latest CNC Machining Centres, and advanced full-automatic die casting machines from 300T to 1000T with an annual capacity of million pieces of parts. All these factors save much cost from elaboration. |

| Work Team | A professional team with a decade of CNC experience, we make the work more efficient to save much time and financial cost. |

If you are looking for a low CNC service price, please do not hesitate to get a quote!

Applications of CNC Machining

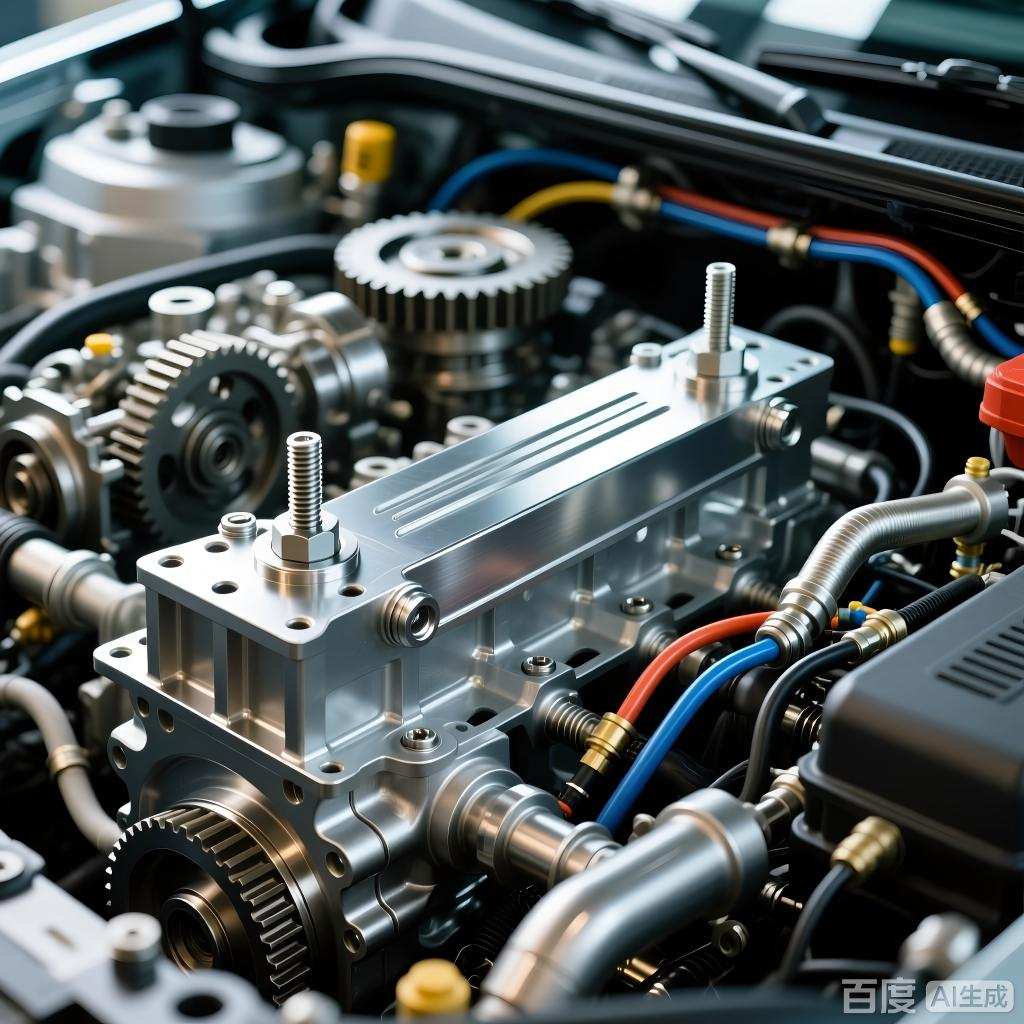

CNC Machining for Automotive Industry

CNC machining is commonly used in the automotive industry, it’s been used to create one-off custom parts. And the CNC is no quantity limitation to automotive parts because the turnaround time is so fast. Because the CNC process uses CAD/CAM software to upload detailed project specifications to an automatic-driven machine, there is little manual labor required to manufacture high-quality parts.

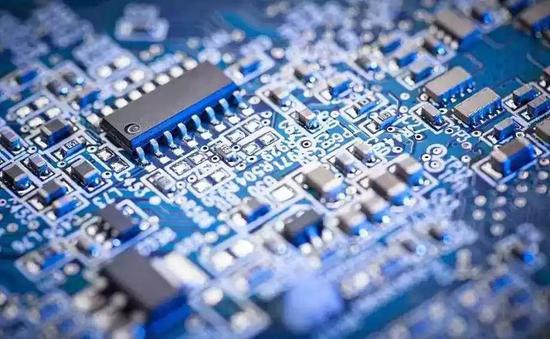

CNC Machining for Semiconductor Industry

The semiconductor industry is actually developed upon electronic information, rigid precision is strict to semiconductor equipment. While CNC machining service can be the replacement, to work on wide various materials, such as silicon, sapphire, nitride alumina, aluminum, etc. It is common that semiconductor CNC machining parts can be seen in different electronic components and integrated circuits.

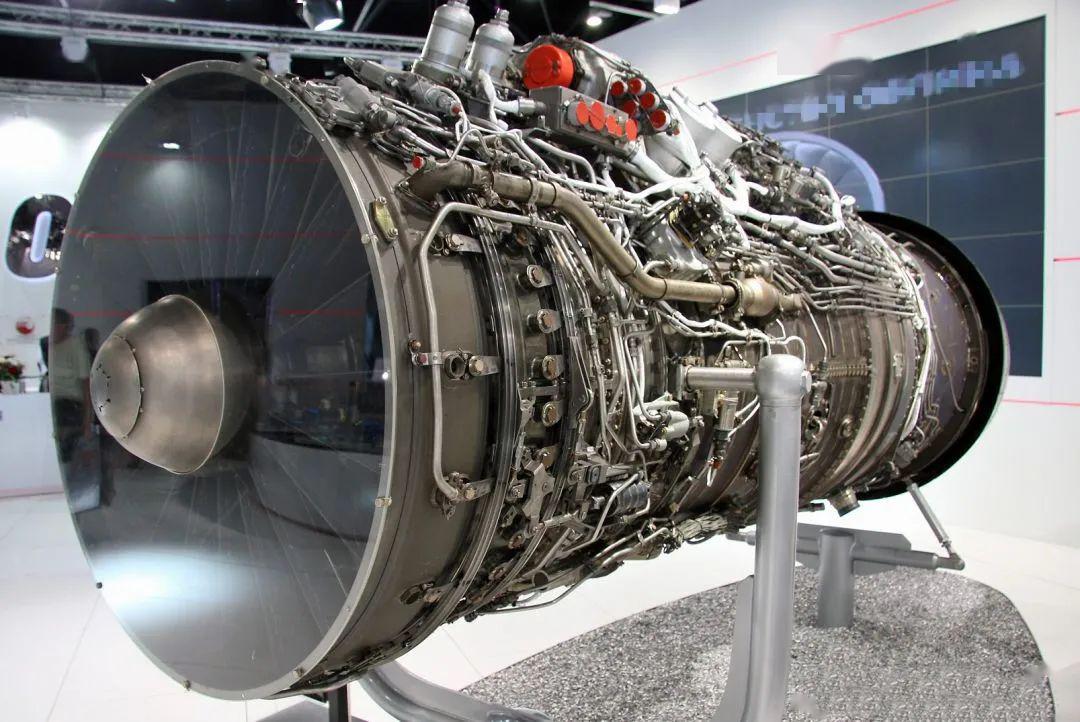

CNC Machining for Aerospace Industry

CNC machining technique has a long-time history in the aerospace. The aircraft components need to be at the highest level of precision. This is so strict with safety-critical application requirements. While JTR MACHINE can make the perfect part for aircraft components. What’s more, our compatible material options for CNC engineering are in a wide range.

CNC Machining for Agriculture Industry

most agricultural parts are huge and complicated, all of them are used on the agricultural equipment ought to be carefully worked with high demands of technical specifications including ultra-high-precision specifications, and lighten durable materials to last the machine’s service life. So customized CNC machining plays a crucially important role in the agriculture industry. What’s the most important reason is that the custom CNC agriculture parts make your equipment more competitive in the market.

CNC Machining for Food Industry

CNC machining is getting more and more attention in the food industry, this is growing with the development of the industry. The food industry nowadays needs the highest quality components and equipment. Operating standards in the food industry have changed dramatically over the past few decades due to more regulations on food contaminants, pathogens, and allergens. We have developed current Good Manufacturing Practice (CGMP) to review and update these food safety regulations.

CNC Machining for High-tech Industry

The new and high-tech industry is a collection of enterprises engaged in the research, development, production, and technique service of one or more technologies and high-tech products. With higher economic and social benefits, the high-tech industry developed rapidly in recent years even though it’s not easy. Precision online CNC machining services for the high-tech industry are keeping up with the trend, providing multiple processing to manufacture and handle various high-tech CNC machined parts.

CNC Machining for Machine Tool Industry

The increasing demand for advanced equipment in various industries represents a great opportunity for the machine tool industry. The machine tool industry is the manufacturing industry that provides processing equipment, is the foundation and core department of the equipment manufacturing industry. Machine tools are also the basic production equipment of the machinery industry.

CNC Machining for Marine Industry

For the shipbuilding industry, the need for innovative devices will certainly boost day by day, which is undoubtedly a good chance for CNC machining services. Since most ship components can be completed by CNC Machining. In the shipbuilding industry, there is a great demand for high-quality precision components. In order to satisfy the requirements of the shipbuilding industry for devices levels, the parts of ship devices should be generated with stringent layout, strict resistances, ultra-high accuracy as well as the most appropriate products.

CNC Machining for Medical Industry

The reason why CNC Machining can be used in the medical field is that it can meet the strict requirements for the quality and consistency of medical devices. Complicated surfaces and geometric shapes are not a problem, and the final product strictly complies with the safety and precision requirements of the medical industry.

Medical machinery is complex, the parts required are brand new, and there is no room for fault tolerance. The parts must be durable, high-quality, and have a smooth surface.

CNC Machining for Military Industry

As an experienced rapid custom CNC machining parts manufacturer and exporter in China, we are a reliable partner to military clients, providing enhanced quality CNC military parts, components, assemblies, and military CNC machining China services with trusted delivery, high-level precision, accurate dimensions, detailed specifications, and intra-budget machining cost.

Why Choose JTR For CNC Machining?

10+ Years of Experience In CNC Machining

▼ 100%QC Quality Inspection Before Delivery

▼ Factory Price/ Excellent Quality

▼ No MOQ/ High Precision/ Short Delivery Time

▼ 24 Hours Online Service/ Fast Quote/ Best After-sale Service

Our Partners

Our CNC Machining Center

Our CNC machining center has more than 70 advanced equipment, which is equipped with 3-axis, 4-axis, and 5-axis CNC machines, able to manufacture parts that meet most requirements from customers. In addition to CNC machining centers, there are also advanced full-automatic die casting machines from 300T to 1000T with an annual capacity of million pieces of parts.

FAQ

CNC Machining Resources

Try JTR Out Now In Just A Few Steps

Upload your 2D/3D files

Start by choosing your preferred manufacturing process, then upload your design file.

Choose the process

Start by choosing your preferred manufacturing process, then upload your design file.

Order your parts online

Start by choosing your preferred manufacturing process, then upload your design file.

Receive your parts

Start by choosing your preferred manufacturing process, then upload your design file.