Capabilities | Materials | Products | Surface | Tolerances | Why Choose JTR

CNC Milling Service

JTR provides CNC milling services for custom CNC parts of any specification, in any material. JTR can help you quickly create designs from simple straight lines to complex geometric shapes and deliver them quickly.

CNC milling is a CNC machining process that uses rotary cutting tools, that move along multiple axes to remove material from a block. CNC Milling can provide custom services for any type of CNC part, whether plastic or metal, simple or complex. We got 3-axis, 4-axis, and 5-axis CNC milling centers with high-precision equipment and experienced crews. JTR can help you quickly create designs from simple straight lines to complex geometric shapes and deliver them quickly. This allows your team to focus on bringing your product to market. If you are looking for a reliable CNC milling company, then JTR is your best choice!

Our CNC Milling Capabilities

Fast Machining

Fastest high-precision will be produced within 1 day.

Quality Assurance

We have ISO9001:2008 and TS16949 quality system certification to ensure the good quality of our products.

Short Delivery Time

Our products will be sent to your door within the fastest time we can do.

Our experienced engineers can design the best processing technology and select the appropriate tool according to the customer’s drawings to quickly mill and obtain a good processing surface, maintain strict tolerances, and ensure the best quality. We can provide all types of customized CNC milling parts to meet your project needs. If you encounter any problems when completing CNC milling parts, please contact us and try to get a solution from JTR.

Available Materials for CNC Milling

CNC Milling Products

Surface Finishes for CNC Milling

Aluminum

Anodizing, Bead blasting, Powder Coating, Electroplating, Polishing, Brushing, Painting

Plastic

Polishing, Brushing, Bead blasting

Other Metals

Bead blasting, Powder Coating, Electroplating, Polishing, Brushing, Painting

Process Specification Requirements

| MAX. Part Diameter | Metal components | Plastic components |

| 3-axis | 1500mm(59.055″) | 1500mm(59.055″) |

| 4-axis | 350mm(13.779″) | 350mm(13.779″) |

| 5-axis | 500mm(19.685″) | 500mm(19.685″) |

| MIN. Part Diameter | Metal components | Plastic components |

| 3-axis | 0.3mm | 0.3mm |

| 4-axis | 0.3mm | 0.3mm |

| 5-axis | 0.3mm | 0.3mm |

Lowest CNC Service Price

4 factors made our lowest price

| CNC Time | The numerical control rate is estimated to be 60%. Thus we can shorten the complishment time and labor cost at the best level. |

| CNC Materials | We are able to provide you with many kinds of of materials at your favorable price. |

| CNC Equipment | 70 latest CNC Machining Centres, and advanced full-automatic die casting machines from 300T to 1000T with an annual capacity of million pieces of parts. All these factors save much cost from elaboration. |

| Work Team | A professional team with a decade of CNC experience, we make the work more efficient to save much time and financial cost. |

If you are looking for a low CNC service price, please do not hesitate to get a quote!

CNC Milling Tolerances

± 0.005mm(metal) / ±0.05mm(plastic)

Why Choose JTR for CNC Milling?

Lead Time – JTR Machine uses the latest CNC machines to produce high-precision and fast-milling parts, the fastest time is within one day, to offer our customers a very short lead time.

Quality Guaranteed – We can provide all types of customized CNC milling parts to meet your project needs. Our experienced engineers will design the milling process and select the appropriate tool based on your drawings, then do the milling quickly while obtaining a good processing surface. By maintaining our strict tolerances, we ensure you the best quality.

Low cost – With our more than 70 CNC machining centers and a super cooperative professional work team, we can make the production cost at the lowest level by shortening the production time, labor cost. We at the same time can offer you some free services such parts assembling which will be based on your needs.

More material and surface finishing options – In addition to time-saving, another advantage of CNC milling is that various types and specifications of plastics and metal blocks can be used for milling. CNC milled parts can also be subjected to different types of surface treatment, such as painting, anodizing, and chrome plating. The perfect combination of functionality and omnipotence.

Ability to handle complex parts – Since the cutting tool of the milling machine can approach the workpiece from multiple different angles, it is possible to create CNC parts with complex shapes. With more axes, more complex parts can be created. If your CNC project requires irregular shapes, milling is usually the best choice.

Overview of CNC Milling

What is CNC Milling?

CNC Milling is a type of CNC machining process that uses rotary cutting tools, that move along multiple axes, to remove material from a block. Our CNC milling process uses 3-axis, 4-axis and 5-axis indexed milling to rapidly cut a choice of more than 30 engineering-grade thermoplastics and metals into complex shapes and precision components.

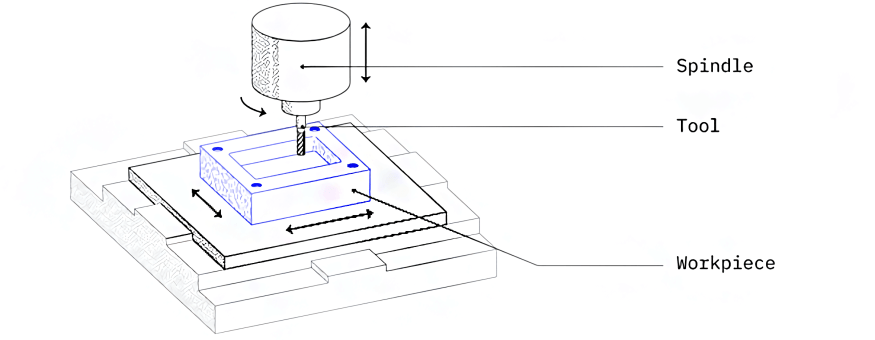

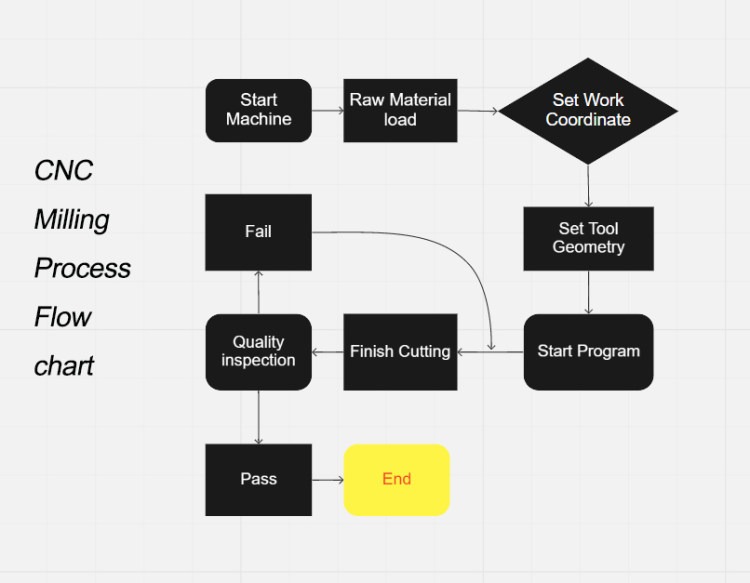

How Does CNC Milling Work?

Like other machining processes, CNC milling starts with designers using CAD (computer-aided design) software to create digital parts. Then the file is converted into “G code”, thus can be recognized by the CNC milling machine.

The CNC milling machine has a “worktable” and workpiece fixing devices to fix a large piece of material (called a “workpiece”) in place. The workbench may or may not move, depending on how the machine is set up.

In the process of CNC milling, a rapidly rotating cutting tool comes into contact with the workpiece, thereby cutting away the material. The tool moves according to the G code instruction to cut in the correct position until the part is completed. Some CNC milling machines use moving tables to create more cutting angles.

CNC rolling mills can cut through hard metals. This makes them more versatile than CNC milling machines, which are similar to 3-axis milling machines but have a weaker ability to penetrate hard materials.

A CNC milling machine is different from a CNC lathe or turning center. In a CNC lathe or turning center, the workpiece rotates instead of the cutting tool.

Different Types of CNC Milling

CNC milling machines are usually defined by the number of their axes. More axes mean they can move their tools and/or workpieces in more ways, thus providing greater cutting flexibility and being able to produce more complex parts in less time.

3-axis: Standard CNC milling cutters have a 3 axis, allowing the spindle (and connected cutting tool) to travel along the X, Y, and Z axes. If the cutting tool cannot reach the part area, the part must be removed and rotated manually.

4-axis: Some CNC milling machines add extra degrees of movement by rotating on a vertical axis. This provides greater flexibility and can create more complex parts.

5-axis: The most advanced type of CNC milling machine widely used is a 5-axis milling machine, which adds two additional degrees of motion by increasing the rotation of the table and spindle. Parts usually do not need multiple settings, because the rolling mill can move them to different positions.

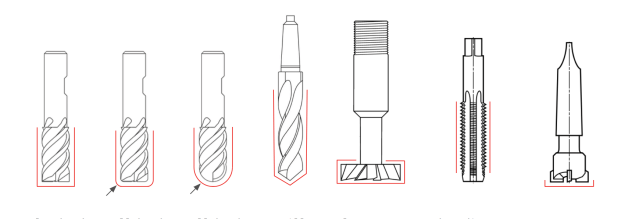

CNC Milling Tools

CNC milling machines can be equipped with different knives/tools to achieve different types of cutting. These tools include end mills, face milling cutters, slab milling cutters, fly cutters, ball cutters, hollow cutters, roughing end mills, etc.

Try JTR Out Now In Just A Few Steps

Upload your 2D/3D files

Choose the process

Order your parts online

Receive your parts