Medical device manufacturing continues to push the bounds of precision, and medical CNC machining remains at the forefront of this development. By 2026, the increasing demand for minimally invasive procedures, personalized implants, and intelligent surgical systems will have reshaped how manufacturers approach the subject of CNC machining in medical industry. Beyond precision alone, success now is pegged on advanced technologies, strict regulatory compliance, and production processes digitally more transparent.

The following article provides a full overview of the 2026 medical CNC machining market, from exploring growth trends and key technologies to regulatory barriers, and best practices in using high-value materials like medical-grade titanium alloy.

Market Overview: Growth Trajectory of Medical CNC Machining

Medical electronics constitute one of the most rapidly expanding markets within the continuum of advanced production techniques. The final results of the research studies depict a pattern where the medical sector contributes more to the CNC machining requirements worldwide as the years go by. The sector is anticipated to see remarkable growth, considering the 9.2 % CAGR expected for the general CMC industry by 2035.

Regional Growth Drivers

The Asia-Pacific region has become the most important growth engine. China and Southeast Asian countries are examples of nations that have three related favorable trends:

- Rapid population aging and increased chronic disease prevalence

- Expansion of medical tourism and private healthcare investment

- Rising disposable income and demand for advanced medical treatments

By 2035, the Asia-Pacific region will contribute about 43% of the medical CNC machining market, taking over global supply chain management and sourcing.

Three Defining Technology Trends in Medical CNC Machining (2026)

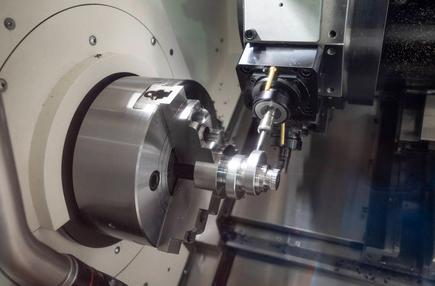

1. Swiss-Type Machining and the Push Toward Miniaturization

The proliferation of minimally invasive surgery (MIS) and implantable electronic devices has led to the development of very small scale medical components. Acceptable examples of such components are screws for bones and teeth, all sorts of catheter parts, and pacemaker system parts.

Swiss-type CNC lathes with guiding bushings that hold material close to the cutting zone are now necessary for these tasks. In 2026, top facilities will regularly be able to get tolerances as tight as ±0.0001 inches (≈2.5 μm). This will make sure that the quality of medical CNC machining medical parts stays the same.

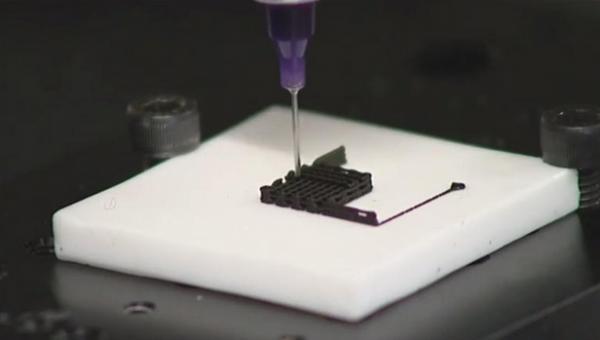

2. Hybrid Manufacturing: Additive + Subtractive at Scale

Hybrid manufacturing, which combines 3D printing and CNC machining, has gone from being a specialist option to the industry norm.

In medical applications, patient-specific implants are often produced by:

- Using data from CT or MRI scans to make 3D prints of complicated, porous structures that look like bone

- Using 5-axis CNC machining to polish joint surfaces, threads, and interfaces with micron-level accuracy

This method cuts down on material waste by more than 40% compared to purely subtractive methods, and it also makes it possible to manufacture designs that were unachievable before.

3. Intelligent Closed-Loop Monitoring and AI Compensation

Mistakes are quite expensive when cutting high-end materials like titanium or cobalt-chromium alloys. AI-driven technologies will be used as “digital quality inspectors” during the machining process in 2026.

Key capabilities include:

- Thermal error compensation, where sensors monitor spindle heat and automatically adjust tool offsets

- Tool wear prediction, allowing tools to be replaced before catastrophic failure

As a result, scrap rates in high-value medical CNC machining have dropped to near-zero levels in advanced facilities.

Regulatory and Compliance Barriers in 2026

1. FDA QMSR Comes Into Full Effect

February 2026 was a big day for rules when the U.S. FDA’s Quality Management System Regulation (QMSR) went into force. The new framework makes sure that FDA standards are completely in line with ISO 13485:2016.

For CNC machining suppliers in the medical industry, this means:

- Mandatory digital Device History Records (DHRs)

- End-to-end traceability of materials, processes, and inspection data

- Significantly higher documentation and audit readiness requirements

2. Elevated Biocompatibility and Cleanliness Standards

Dimensional accuracy alone is no longer sufficient. Regulatory scrutiny now extends to:

- Surface roughness and micro-finish quality

- Residual cutting fluids or contaminants

- Validation of medical-grade cleaning processes

These regulations make it harder to get in, but they also safeguard high-quality providers against competitors who don’t follow the rules and offer low prices.

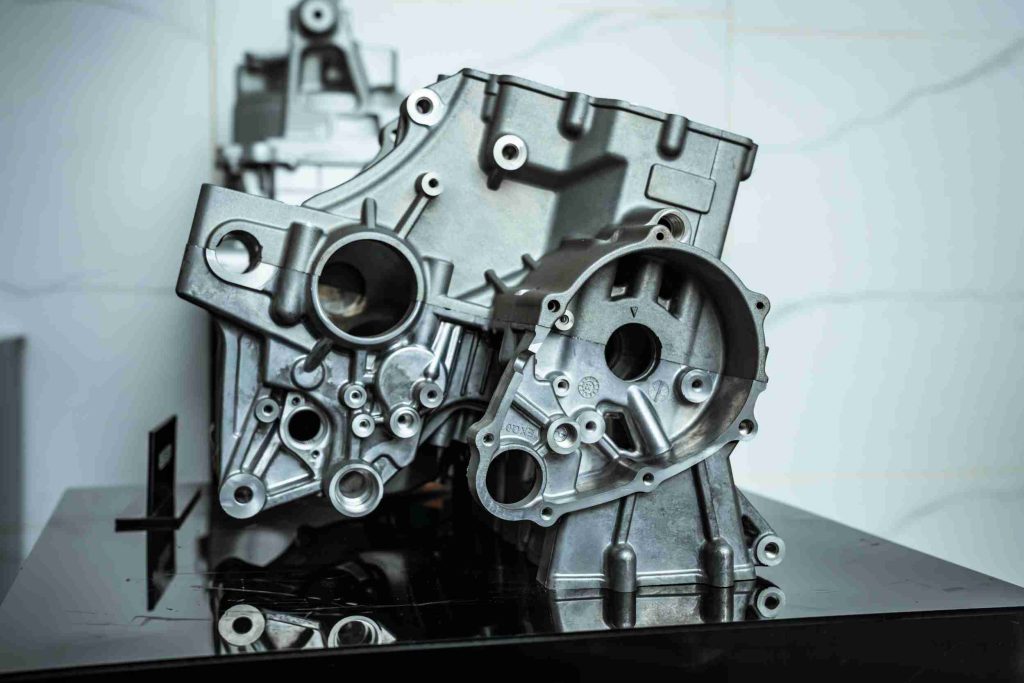

Material Trends in Medical CNC Machining (2026)

Medical CNC machining is becoming more focused on a small number of high-performance materials:

- Titanium alloys (Ti-6Al-4V ELI) for implants

- Cobalt-chromium alloys for joint parts that don’t wear down easily

- Medical stainless steels for tools used in surgery

- Engineering plastics (PEEK, PPSU) are used for parts that need to be light or see-through.

Of these, titanium is still the most technically difficult and valuable.

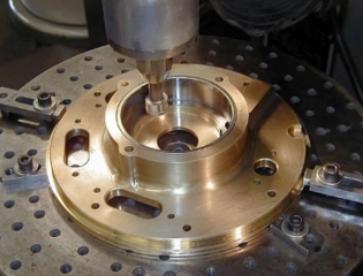

Best-Practice CNC Machining Strategies for Medical-Grade Titanium

1. Advanced Cutting Parameters

Machining strategies have changed from traditional low-speed, heavy cuts to high-speed machining (HSM) by 2026. With AI-assisted adjustment, completion speeds now go beyond 120 m/min, while the surface roughness stays below Ra 0.4 μm, which is an important limit for implant applications.

2. Tooling Selection and Geometry

Medical titanium machining requires exceptional tool stability:

- Ultra-fine-grain carbide tools are mandatory

- Advanced coatings such as AlTiN, TiAlN, and increasingly DLC (diamond-like carbon) reduce adhesion and heat buildup

Optimized geometry plays a vital role:

- Rake angles of 10–15° reduce cutting forces

- Unequal helix angles of 35–40° suppress chatter in thin or delicate parts

3. Cooling and Lubrication Technologies

Cooling accounts for up to 70% of tool life in titanium machining:

- High-pressure internal cooling (≥70 bar) is now standard

- Minimum Quantity Lubrication (MQL) is preferred for micro medical parts to minimize residue

- Cryogenic machining using liquid nitrogen is gaining traction for aerospace-grade titanium, extending tool life by 2–3×

Special Process Controls for Medical Applications

1. Residual Stress Management

Titanium components are prone to distortion due to residual stress. Best practice includes:

- Separating roughing and finishing stages

- Vacuum annealing between 595–705°C to stabilize dimensions

2. Contamination Prevention

Cutting fluids containing chlorine or sulfur are strictly prohibited, as they can cause stress corrosion cracking and compromise biocompatibility.

3. Thin-Wall and Complex Geometry Support

Medical implants often feature ultra-thin walls. Advanced strategies such as layered contour machining and adaptive CAM toolpaths reduce elastic deformation and dimensional drift.

Common Challenges and Modern Solutions

- Work hardening: Continuous feed rates prevent surface hardening and tool chipping

- Chip control: Modern CAM software generates trochoidal toolpaths to force chip breakage

- Batch consistency: AI-driven compensation ensures dimensional stability over 24-hour production cycles

Market Opportunities in 2026 and Beyond

1. Surgical Robotics

The rise of intelligent surgical robots has created strong demand for precision-machined joints, miniature gearboxes, and high-tolerance assemblies.

2. Cost-Effective Medical Robotics

Affordable robotic systems for mid-sized hospitals are driving volume orders for standardized precision components.

3. Digital and Transparent Supply Chains

Leading medical OEMs increasingly favor CNC machining partners with:

- Real-time production dashboards

- Digital twin simulations

- Predictive capacity planning

These capabilities enhance supply-chain resilience and shorten time-to-market.

Conclusion: Who Will Lead Medical CNC Machining in 2026?

In 2026, success in medical CNC machining depends on far more than machining accuracy alone. The industry’s leaders will be those who combine:

- Advanced machining technologies

- Deep regulatory expertise

- AI-enabled process control

- Fully digitalized, transparent production systems

Choosing the proper CNC machining partner for the medical industry is no longer just a matter of finding the correct supplier. It’s now a strategic investment in safety, compliance, and long-term competitiveness for both makers and purchasers.