Today, precision, speed, and flexibility are even more essential in the automotive landscape. CNC automotive parts now form the bridge between high-performance design and efficient production-they are the very backbone of modern vehicle production. The appeal of CNC machining in automotive industry applications has been on an almost self-fulfilling upward spiral, thus significantly boosting demand from high-speed racing cars to electric vehicles (EVs).

Engagement with a dominant supplier mandates the presence of CNC machines due to their unmatched accuracy, flexibility, and repeatability. In this article, the development of CNC technology, 5-axis CNC machining for automotive, micro-machining for sensors, and rapid prototyping will be discussed.

What Are CNC Automotive Parts? Applications Across Modern Vehicles

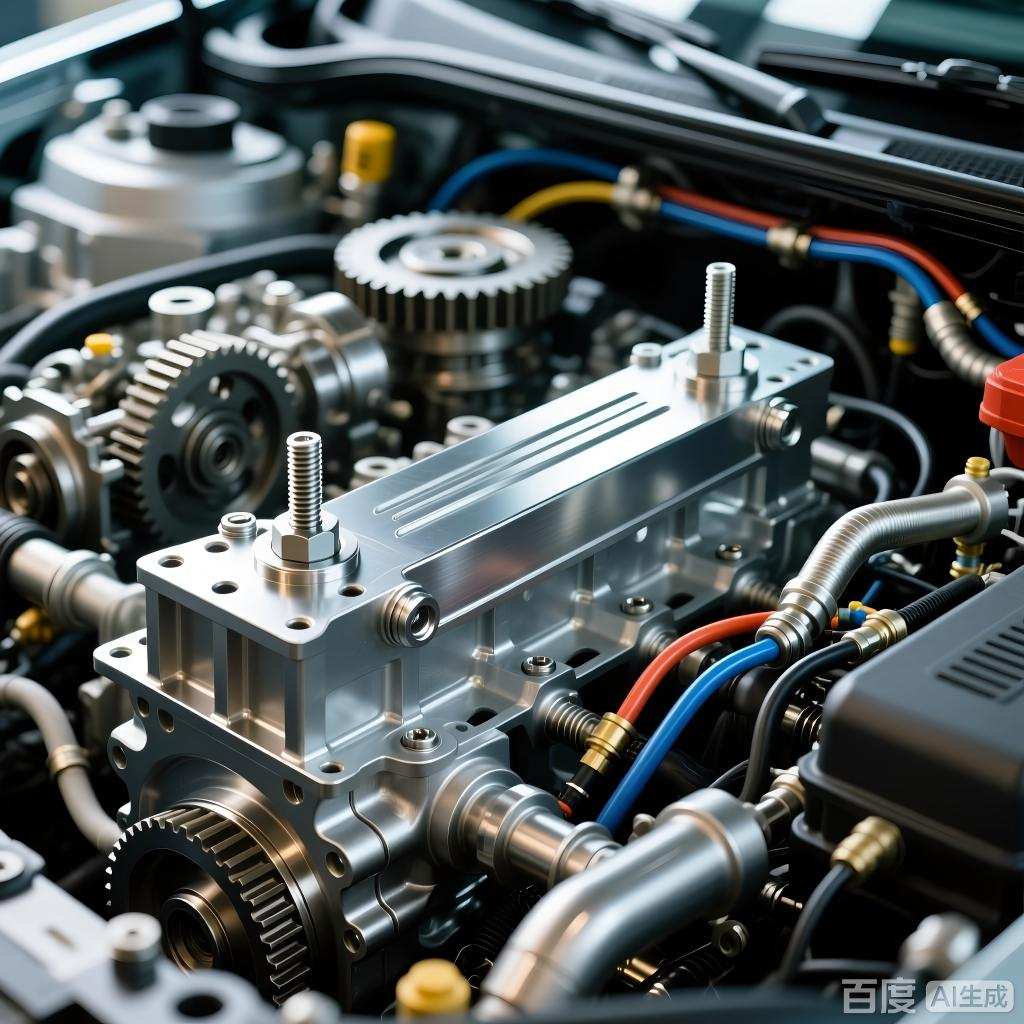

CNC automotive parts manufacturing is computer-controlled machining equipment that creates the sections to cover every portion of a vehicle, including engine components, chassis structures, and electronic housings.

Common Applications:

- Engine & Powertrain Components: Tight tolerances and the finest surface finish translate to disparate parts such as cylinder heads, camshafts, and transmission components.

- Chassis & Suspension Systems: CNC machining of brackets, mounts, and control arms ensures durability and dimension repeatability.

- EV Battery Housings & Cooling Components: Modern EV battery system thermal management and precise fits are achieved through CNC machining.

- Sensor Housings & Electronics Enclosures: Precision CNC processes manufacture another type of component used in miniaturized applications for ADAS and automotive electronics.

For making high-precision automobile components, CNC machining becomes a necessary tool due to its repeatability, precision, and high-quality finishes.

CNC Machining in the Automotive Industry: From Prototyping to Mass Production

The role of CNC machining in automotive industry extends from prototyping to full-scale production.

- Rapid Prototyping Automotive: Engineers can now fabricate prototypes quickly so that they can serve as functional tools, which will help with design validation, allowing for shorter product development cycle times.

- Pilot Runs & Low Volume Production: Low quantities of high-quality precision components can be manufactured by CNC machining before deciding whether or not to mass produce.

- Full-Scale Manufacturing: Automated multi-axis machines help CNC manufacturing to handle medium-to-high quantities, maintaining quality all the time.

CNC machining provides an inimitable freedom of design compared to casting or forging processes, as tooling does not have to be modified expensively when new designs come. This feature is very beneficial when it comes to EVs, self-driving vehicles, and fast track automotive technologies.

5-Axis CNC Machining for Automotive: Complex Geometry Made Possible

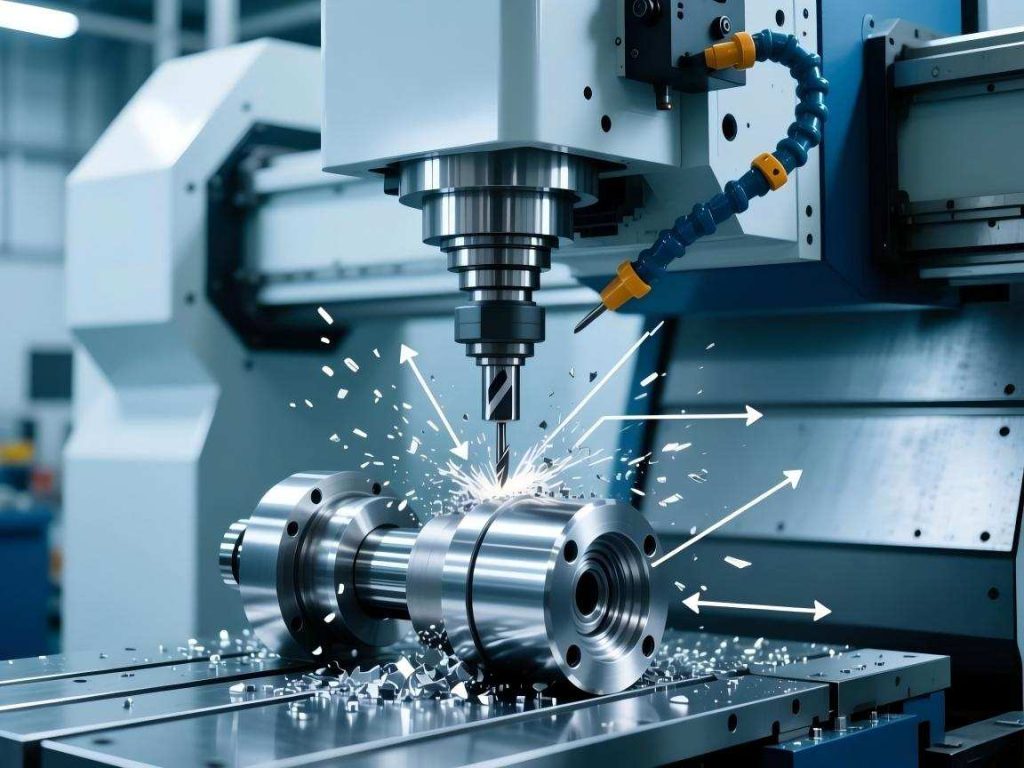

5-axis CNC machining for automotive has revolutionized how manufacturers approach complex geometries. Unlike traditional 3-axis machines, 5-axis systems can move a part along five different axes simultaneously, reducing setup times and increasing precision.

Key Benefits:

- One-Time Setup for Complex Parts: Eliminate multiple fixtures and manual repositioning.

- Improved Dimensional Accuracy: Reduce human error and improve surface quality.

Applications in Automotive:

- Complex engine components

- Intricate sensor housings

- High-performance racing parts with tight tolerance curves

By incorporating 5-axis machining, automotive manufacturers achieve intricate designs with exceptional efficiency and consistency.

High-Precision Auto Parts: Meeting Tight Tolerances and Automotive Standards

Automotive parts can pass strict dimensional accuracy, often measured in microns, and meet a high quality standard like IATF 16949 to ensure the safety, performance, and reliability of vehicles.

Key Considerations:

- Tolerance Control: CNC machining ensures its high-dimensional tolerance control to ensure a perfect fit-and-match.

- Surface Finish: Smooth surfaces contribute to reducing wear and friction and improving fit and assembly integrity.

- Material Compatibility: It can serve aluminum alloys to titanium, consequently having a wide spectrum for material compatibility.

These capabilities make CNC machining an ideal solution for both standard automotive components and specialized high-performance parts.

Micro-Machining for Sensors and Automotive Electronics

Nearly everything in modern vehicles today is characteristic of electronics and sensors, and that includes features such as safety, performance, and connectivity. Micro-machining for sensors entails making very small and intricate components that function perfectly under the harshest conditions.

Applications:

- ADAS Sensor Housings: It generates miniature components for radars, LiDARs

- Pressure, Temperature, and Flow Sensors: Used for engine and battery management

- Micro Channels and Ultra-Thin Walls: Can only be achieved through precise CNC machining

For all these compact designs, automotive electronics were new in high-precision micro-component production to ensure reliable performance.

Material Expertise: Aluminum and Titanium in Automotive CNC Machining

Material selection is as important as machining itself, and attached to that, CNC machining performs excellently with aluminum and titanium materials since both are among the most common high-performance materials in any automotive application.

Machining 6061 vs 7075 Aluminum for Automotive Parts

- 6061 Aluminum: 6061 is a highly machinable aluminum and can be used for most operations. It is cost-effective, corrosion-resistant, and is ideal for making structural components and chassis brackets.

- 7075 Aluminum: Higher strength, fatigue resistance, and aircraft quality. This material is mainly recommended for aerospace-grade and racing applications.

Titanium Racing Parts: Strength, Weight, and Performance

- High Strength-to-Weight Ratio: Critical for lightweight racing parts and high-performance vehicles.

- Heat & Fatigue Resistance: Essential for engine and suspension components under extreme conditions.

- Applications: Custom racing brackets, engine components, and aerospace-inspired automotive designs.

CNC machining ensures both aluminum and titanium parts meet the stringent specifications required for high-performance automotive applications.

Rapid Prototyping for Automotive Innovation

Rapid prototyping in automotive helps manufacturers test designs faster, iterate, and validate designs. Application of CNC machining makes it possible to derive functional prototypes made of the same raw materials utilized in mass production, and consequently leads to a better overview of fit, function, and performance.

Benefits:

- Validation: Check for potential guiding flaws before starting production.

- Pilot Static Testing: Assess strength, thermal, and operational performance.

- Quickened Innovation: Minimize development periods and costs.

Used in collaboration with today’s advanced CNC abilities, fast prototyping evolves as a powerful tool common between OEMs and aftermarket innovators.

Why Choose a CNC Partner Specialized in Automotive Parts

Selecting the right CNC partner can make a significant difference in product quality and delivery. Look for partners who offer:

- Experience in the automotive sector

- Advanced capabilities like 5-axis and micro-machining

- Expertise in aluminum, titanium, and specialty alloys

- End-to-end solutions from prototyping to mass production

A skilled CNC partner ensures reliable, high-quality CNC automotive parts that meet automotive industry standards.

Selecting the correct manufacturing partner is of utmost importance-from the very first phase towards present-day quick prototyping of automotive components up to mass production of auto parts that are high precision. Our capabilities in CNC are created in such a way that they can push forward any project, initiate the next generation of EVs, or push limits with titanium racing parts.

FAQ: CNC Automotive Parts

Q1: What CNC machining processes are used for automotive parts?

A1: Processes include milling, turning, drilling, and micro-machining, often with multi-axis CNC machines for complex geometries.

Q2: Why is 5-axis CNC machining important in the automotive industry?

A2: It allows machining complex parts in a single setup, reducing errors and improving precision.

Q3: Which aluminum grade is better for automotive parts, 6061 or 7075?

A3: 6061 is easier to machine and cost-effective, while 7075 offers higher strength for racing or high-stress applications.

Q4: Can CNC machining be used for rapid automotive prototyping?

A4: Yes, CNC machining allows functional prototypes with precise tolerances, suitable for design validation and testing.

Q5: Titanium parts are ok for racing with autos?

A5: That is right. Titanium has the strength of light to be used in racing as well as high-performance components.