CNC Machining Plastic Parts

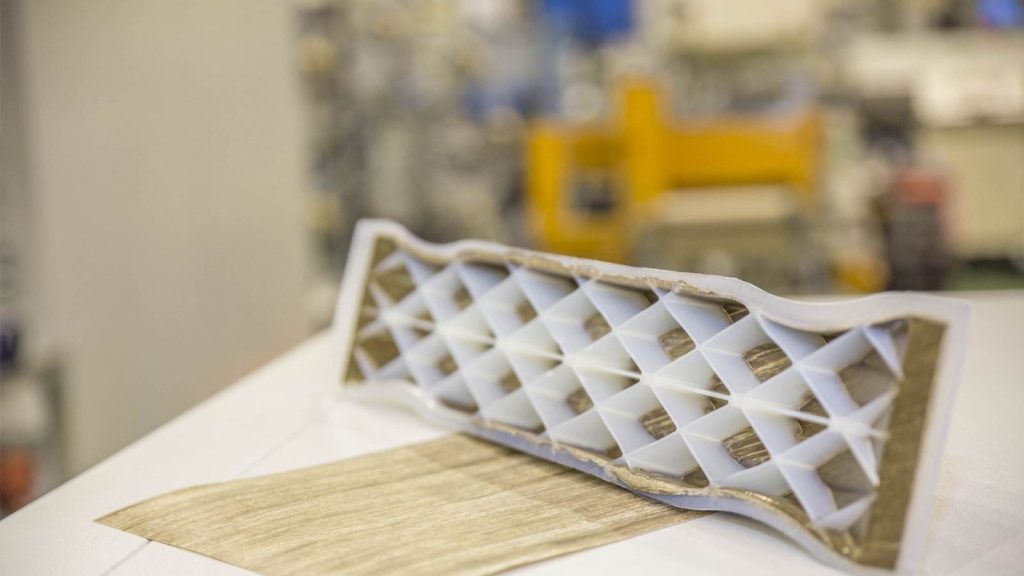

As a high-quality CNC parts manufacturer in China, JTR Machine has a variety of CNC machining capabilities. We have been focusing on CNC machining of high-quality plastics for customers all over the world. Our rapid plastic parts processing services can complete the processing of plastic parts more efficiently, and the extremely advantageous price is the key to our success. Experienced engineers and experts check the quality of your products layer by layer to ensure that your plastic parts have better performance.

Of course, we are fully capable of providing excellent customized services for plastic CNC machining parts. Complex part shapes and surface features can be presented in the best way. Whether you need ABS, nylon, PEEK, PC, or other types of materials, we will choose one according to your parts requirements. You only need to put forward your needs and your drawings, and we will complete your vision. JTR Machine is a Chinese CNC manufacturer that has obtained CE and ISO9001 certification. We provide high-precision, small-tolerance CNC machined plastic parts.

Why Choose JTR Machine CNC Machining Plastic Services?

- More than 8 high-performance engineering plastic materials for you to choose

- Advanced processing and manufacturing technology, complete CNC processing equipment

- A team of engineers with more than 15 years of CNC machining experience, to provide you with the highest quality CNC machining solutions for plastic parts

- Efficient CNC programming, 5-axis machining, precision production capacity.

CNC Machining Plastic Materials at JTR

CNC Machining ABS – Acrylonitrile butadiene styrene (ABS) is a common thermoplastic polymer and CNC processing material. ABS has impact resistance, heat resistance, and flame retardant properties, and the color of ABS is transparent and its strength is excellent. ABS parts can be post-treated by painting, electroplating, and other methods to enhance surface quality and performance.

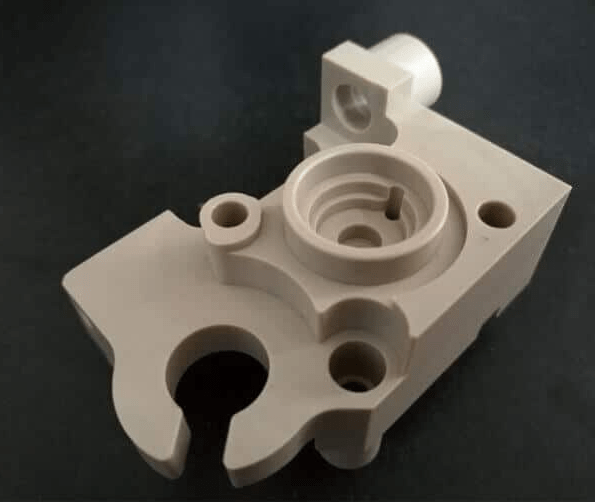

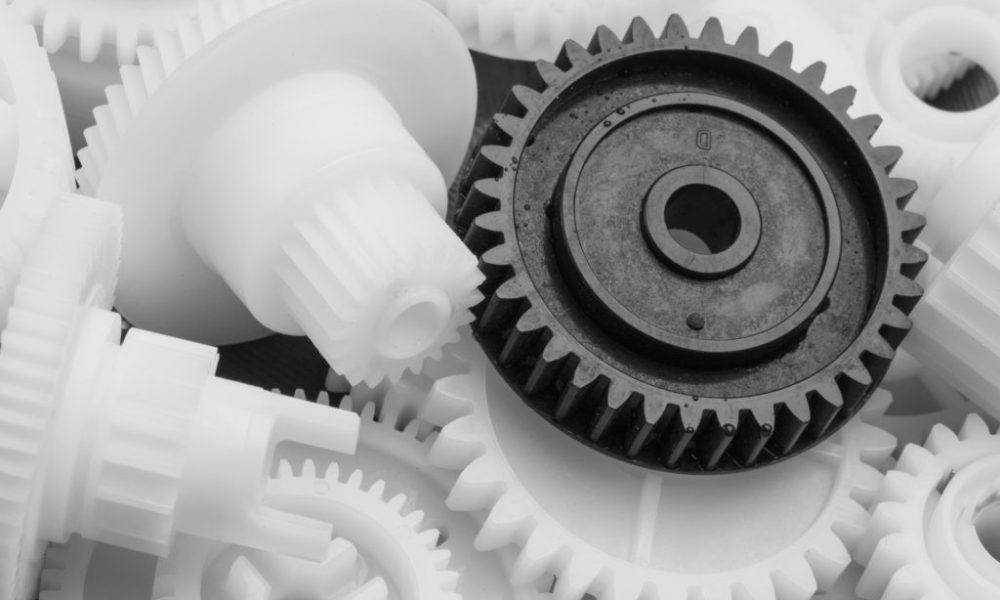

CNC Machining POM (Polyoxymethylene) – POM is a tough elastic material that has good creep resistance, geometric stability, and impact resistance even at low temperatures. The high crystallinity of POM leads to its high shrinkage. The extremely low coefficient of friction and good geometric stability are the reasons why POM has become a high-quality CNC machining material. POM can be applied to any CNC machining parts that require flexibility.

CNC Machining PE (Polyethylene) – Polyethylene (PE) also known as Polythene (IUPAC name polyethylene) is a semi-crystalline thermoplastic. PE offers high levels of toughness with low strength and hardness. It has low moisture absorption, high elongation, excellent chemical resistance, and corrosion resistance.

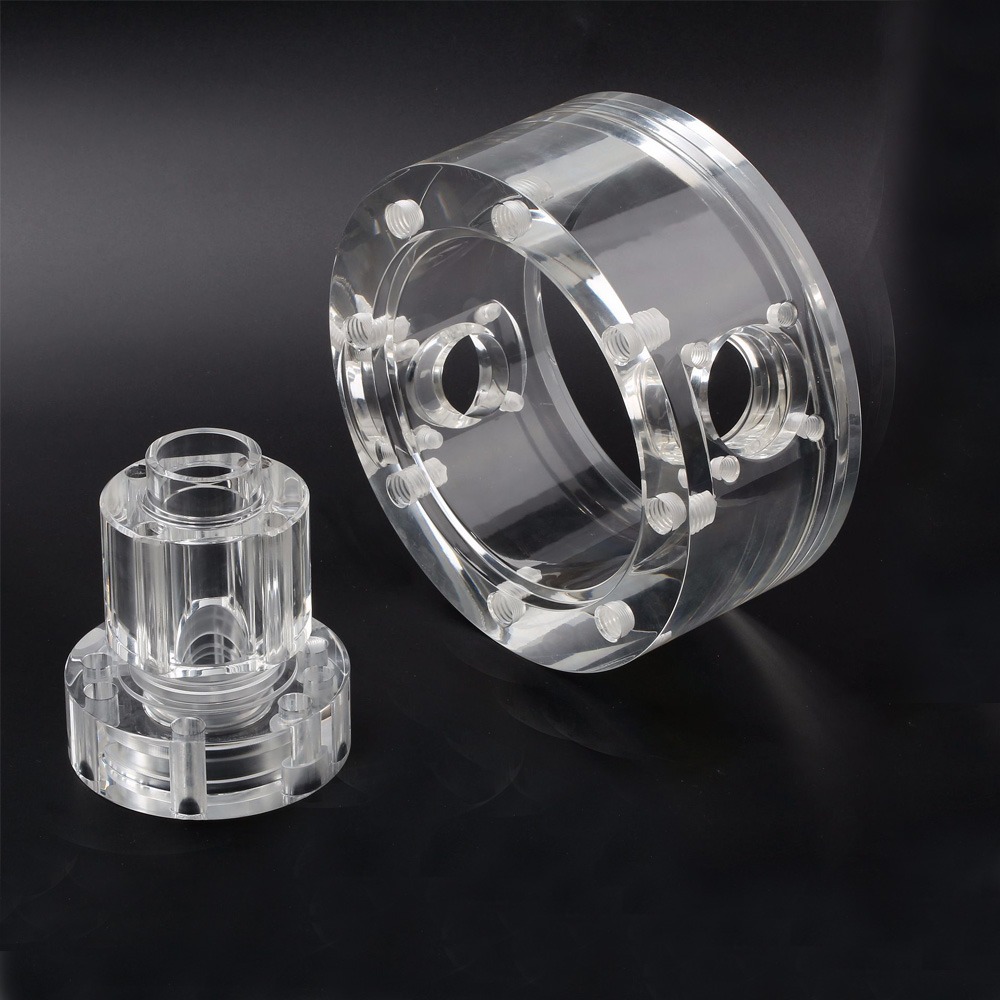

CNC Machining PMMA (Acrylic) – Acrylic (PMMA) is a plastic polymer material. It has good transparency, chemical stability, and weather resistance is easy to dye, is easy to process, and is beautiful.

CNC Machining PA (Polyamide or Nylon) – Nylon has the most superior comprehensive properties, including mechanical strength, stiffness, toughness, mechanical shock absorption, and wear resistance. These characteristics, coupled with good electrical insulation and chemical resistance, make nylon a “universal grade” material for the manufacture of mechanical structural parts and maintainable parts.

CNC Machining PC (Polycarbonate) – Polycarbonate (PC for short) is a high molecular weight polymer containing carbonate groups in the molecular chain. The three major application areas of PC engineering plastics are the glass assembly industry, automobile industry, and electronics and electrical industry, followed by industrial machinery parts, optical discs, packaging, computers and other office equipment, medical and health care, films, leisure, and protective equipment, etc.

CNC Machining PEEK (Polyetheretherketone) – Polyetheretherketone (PEEK) resin is a special engineering plastic with excellent performance. Compared with other special engineering plastics, it has more significant advantages. It has a high-temperature resistance of 260 degrees, excellent mechanical properties, and chemical resistance. In addition, PEEK can be flame-retardant, peel-resistant, and wear-resistant. It can be used as a material in high-end machinery, nuclear engineering, and aviation.

CNC Machining PTFE ( (Polytetrafluoroethylene or Teflon) – Polytetrafluoroethylene or Teflon is a synthetic polymer material that uses fluorine to replace all hydrogen atoms in polyethylene. This material is resistant to acids, alkalis, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high-temperature resistance, and its friction coefficient is very low, so it can be used as a way of lubrication, and it has also become an ideal coating for non-stick pots and water pipes.

CNC Machining PVC (Polyvinyl chloride) – Polyvinyl chloride (also known as PVC) is a polymer formed by vinyl chloride monomer, abbreviated (VCM) in peroxides, azo compounds, and other initiators; or under the action of light and heat according to the free radical polymerization reaction mechanism. Vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resin. PVC used to be the world’s largest production of general-purpose plastics, and it has a wide range of applications. It is widely used in building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, fibers, etc.

Plastic CNC Machining Manufacturer with the Highest Reputation in China

One of the most reliable plastics CNC machining manufacturers in China – JTR, with a professional engineering team and skilled machines operator, also 70 advanced CNC machining centers we are capable to complete the ABS CNC machining efficiently. For plastic like ABS, we have 10 years’ experience in machining any kinds of designs from our customers. In addition to that, we are also able to handle many other kinds of plastic such as PET, PVC, PC, PE, PTFE, POM, PMMA, Nylon, PP and Peek, etc. If you are seeking a reliable plastic CNC machining service manufacturer, please do not hesitate to contact us.