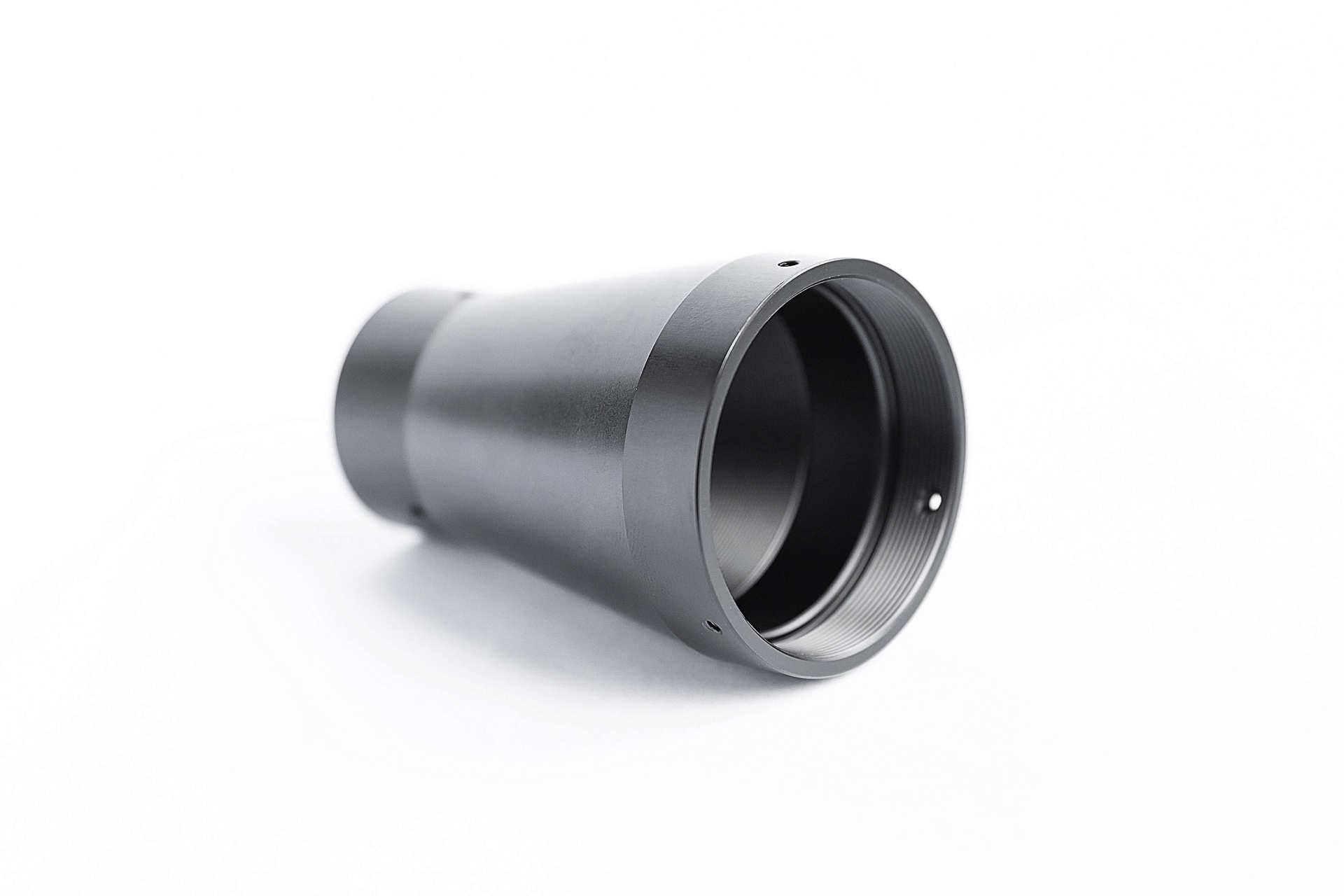

Surface Finishing Service

Apart from product manufacturing services, JTR Machine also provides our clients with multiple surface finishing options, to bring a one-stop manufacturing experience. From designing all the way to finish, our service is the best solution to speed up your project.

We got a team dedicated to surface finishing. we provide surface finishing services for all parts in any quantity, and quality is also guaranteed. Ready to get your product’s surface finished? Contact us and get a quote.

Surface Finishing Options

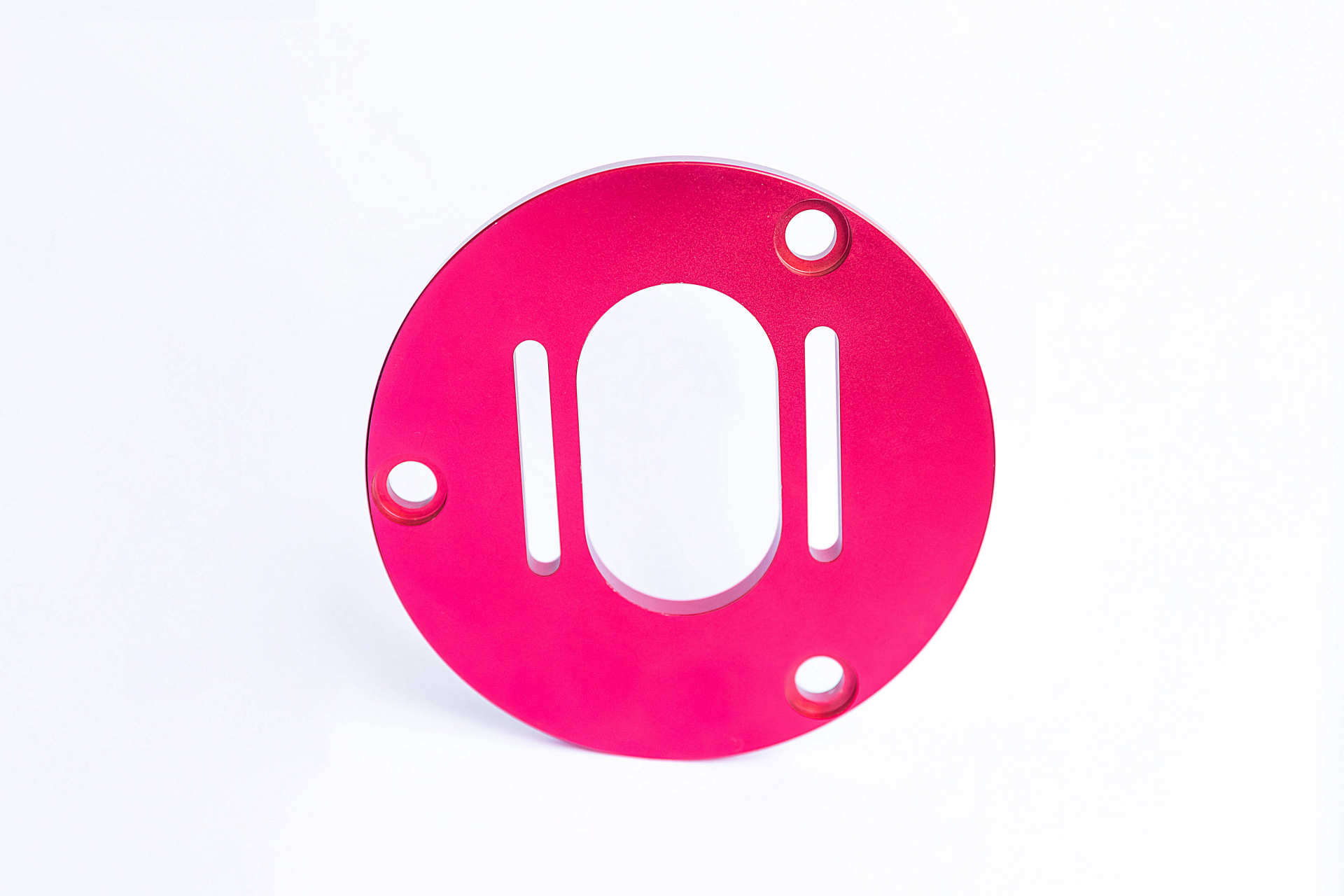

Anodizing

Anodizing, the so-called aluminum anodizing is an electrolytic oxidation process, in which the surface of aluminum and aluminum alloys is usually transformed into an oxide film, which has protective, decorative, and other functional properties. A metal or alloy product is used as an anode, and an oxide film is formed on the surface by electrolysis. The metal oxide film changes the surface state and properties, such as surface coloring, improving corrosion resistance, enhancing wear resistance and hardness, and protecting metal surfaces. Anodization includes sulfuric acid anodization and chromic acid anodization. The colors of sulfuric acid anodization are: grass green, red, black, etc.; chromic acid anodization is mainly gray and generally does not fill color.

Chrome & Galvanized

This type of surface treatment not only creates a protective layer but also has a super-perfect appearance. We provide: Chrome plating refers to the behavior of plating chromium as a plating layer on other metals, and the chromium plating layer has good wear resistance; Zinc plating refers to the surface treatment technology that coats the surface of the metal, alloy, or other materials with a layer of zinc to play a role in aesthetics and rust prevention.

Logos & Symbols

There are multiple ways to create logos, symbols, and text on prototypes or production parts. We can provide Laser marking, silkscreen.

Powder Coating

Powder coating is to keep parts from corrosion, it applies a powder type paint to a component, and baking it onto the part. Options for powder coating are various, from color choice to texture.

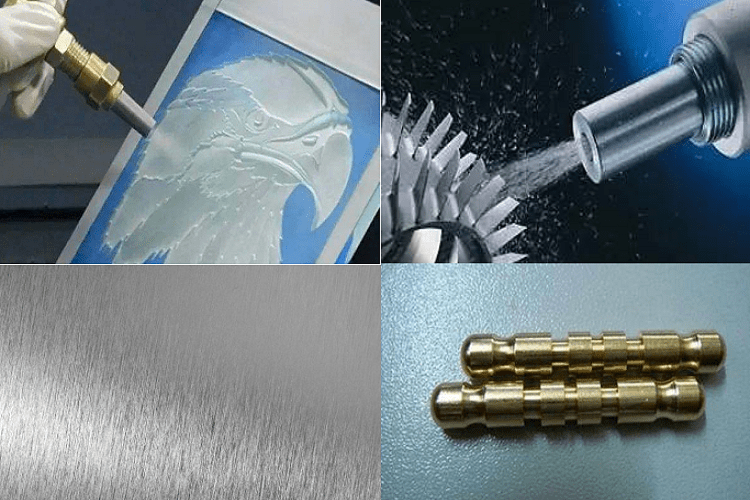

Other Surface Finishing Methods

Powder coat, painting, sandblasting, polishing, shot blasting, wire drawing, passivation. To make sure which method is the best for your parts, contact us and our engineers will sort out the best solution for you.

JTR Surface Finishes, Materials and Colors

| Finishes | Materials | Colors |

| Anodizing | Aluminum/Alloy aluminum/Other metal | Grass green, red, black, etc. |

| Chrome & Galvanized | Steel/Stainless steel/Alloy steel | Bright silver |

| Powder Coating | All metal | Black, blue, yellow, red, etc. |

| Polishing | All metal and plastic | / |

| Blasting | All metal | Black, blue, yellow, red, etc. |

We offer other surface finishing options and logos &symbols, feel free to get a quote!

JTR Surface Finishes

Why Choose JTR for Surface Finishing Services?

Quality Guaranteed – We offer to provide you with the best surface finishing solutions for your parts, quality guaranteed.

Lead Time – Strong production capacity makes the shortest lead times. JTR Machine is also capable of designing and machining the parts – a one-stop service produces parts at a low cost and reduced time.

Design Analysis – We’d offer professional advice based on your design before starting finishing. If you don’t have any idea about what to do with parts, our designers can help you with a brand new design.

Versatility – We offer almost all surface finishing options to almost all materials, no matter how they are processed. Our processes include adding, altering, removing and reshaping the material, meeting the needs for all surface finishing options.

Overview of Surface Finishing

What is Surface Finishing?

Surface finishing refers to different processes used to modify the surface of a finished product to give it a unique or desired appearance. The most commonly used surface finishing options are sanding and polishing, but there are far more methods to choose from. Different technologies are used to improve appearance, adhesion, solderability, corrosion resistance, hardness, electrical conductivity and many other characteristics of industrial components. There are also automated surface finishing processes to reduce production time. But, as it says, there is no best, only the most suitable.

Benefits of Surface Finishing

Improve the appearance

Add specific beautiful colors

Change the luster

Increase wear resistance

Limit effects of corrosion

Enhance chemical resistance

Reduce friction

Remove surface defects

Cleaning the parts

Serve as a primer coat

Adjust the sizes

Surface Finishing FAQ