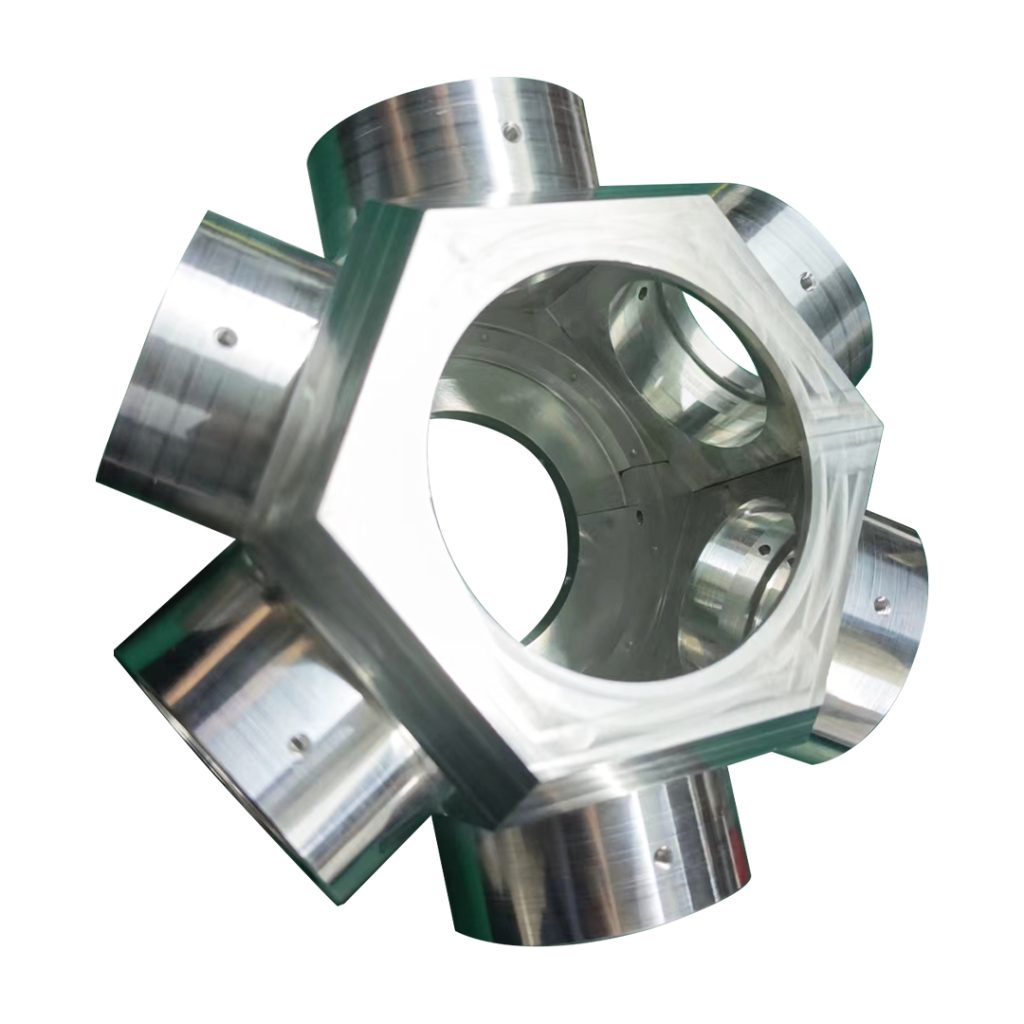

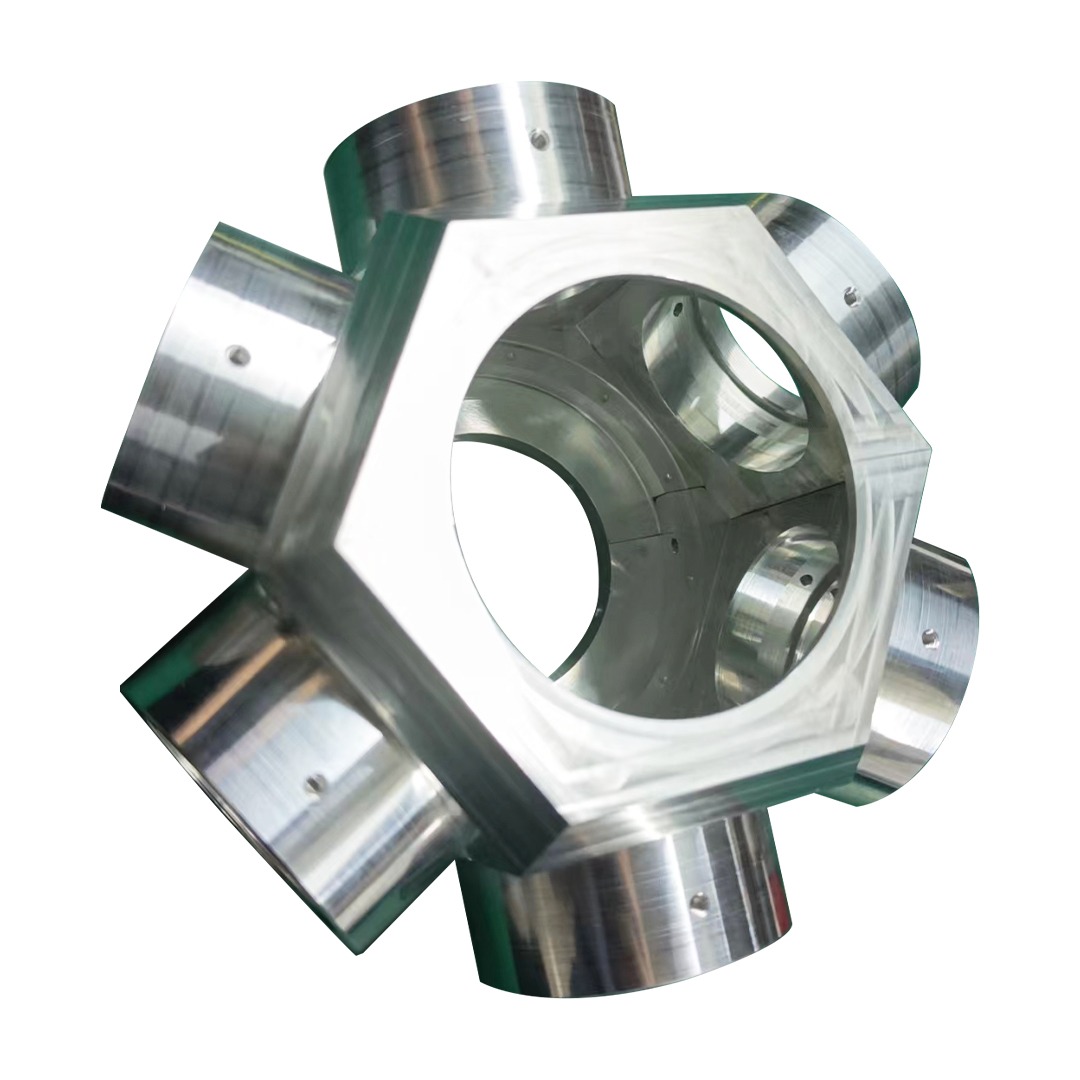

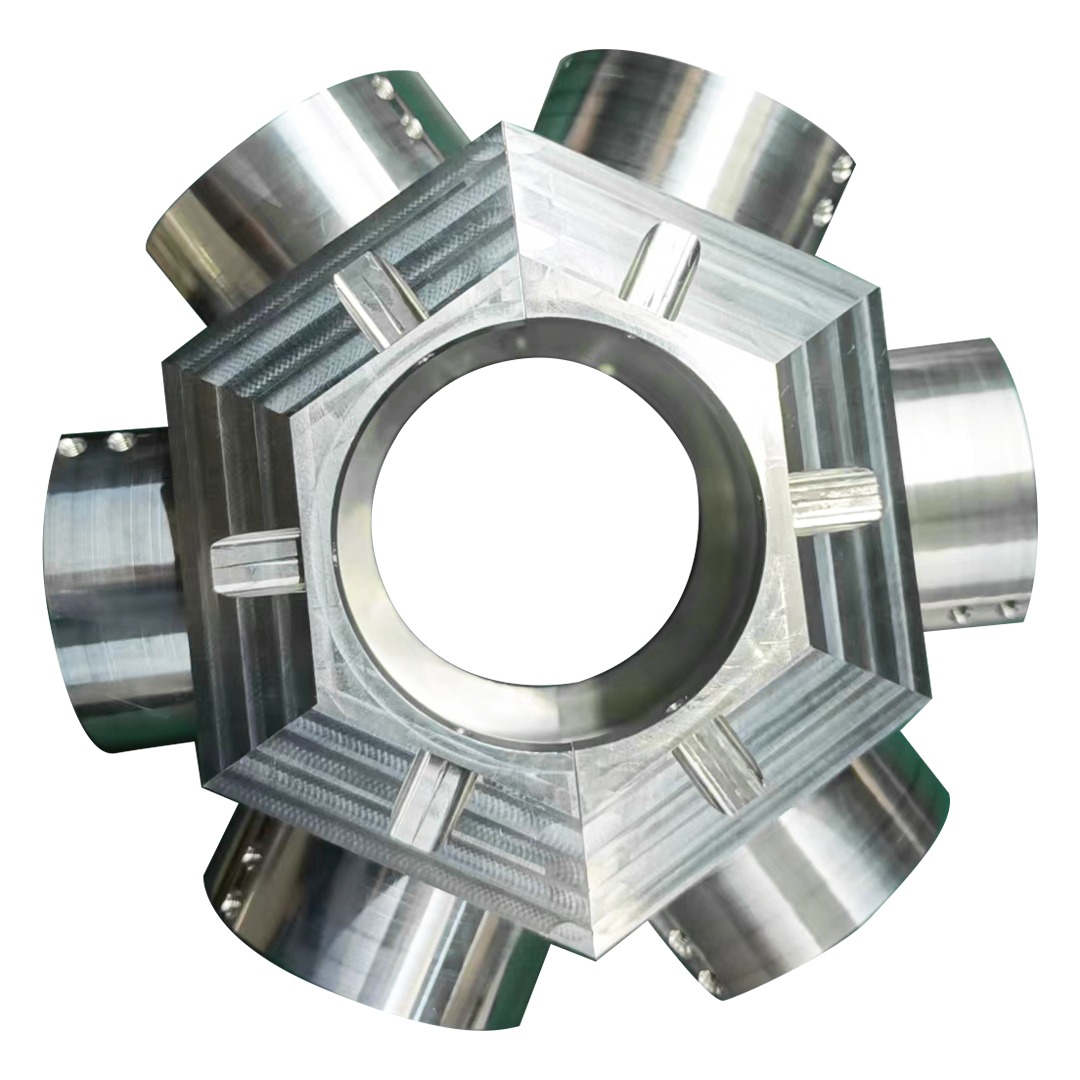

5-Axis CNC Machining Part

- Material: AL6082-T6

- Size: 185*110*97mm

- Process: CNC milling

- Surface treatment: as machined

What Are the Advantages of the 5-Axis CNC Machining Part?

- Craft intricate shapes: Reach tricky angles and curves, impossible with 3-axis machines.

- Finish parts faster: Reduce setups and re-positioning, saving time and money.

- Boost precision: Achieve tighter tolerances for demanding applications.

- Skip extra steps: Machine complex surfaces directly, minimizing post-processing.

- Design freely: Unlimit your creativity with intricate geometries and functionalities.

What Types of Parts Are Typically Made With 5-Axis CNC Machining?

- Aircraft engine components: intricate blades and housings requiring high precision and strength.

- Landing gear parts: complex shapes with tight tolerances for smooth operation and safety.

- Prosthetic limbs: customized and lightweight artificial limbs requiring precise fit and functionality.

- Surgical instruments: delicate tools with complex features for minimally invasive procedures.

- Engine components: pistons, camshafts, and other intricate parts demanding high performance and durability.

- Molding tools: complex molds for creating plastic car parts with precise dimensions and intricate details.

- Sports equipment: golf clubs, bicycle frames, and other gear with aerodynamic shapes and lightweight designs.

- Jewelry and watches: intricate designs and delicate features for high-end jewelry and watch components.

Why Choose JTR?

Chongqing Jin Te Rui Machine Co., Ltd. specializes in providing professional mass manufacturing and rapid prototyping services, including CNC machining, die casting, 3D printing, rapid tooling and injection molding, plastic and aluminum extrusion, sheet metal prototyping, and integrating the design and development of new products. In a matter of hours, we can swiftly realize your design thanks to our excellent manufacturing solutions. This lets you test the product thoroughly and make all the necessary changes to improve the design before launching into full production.