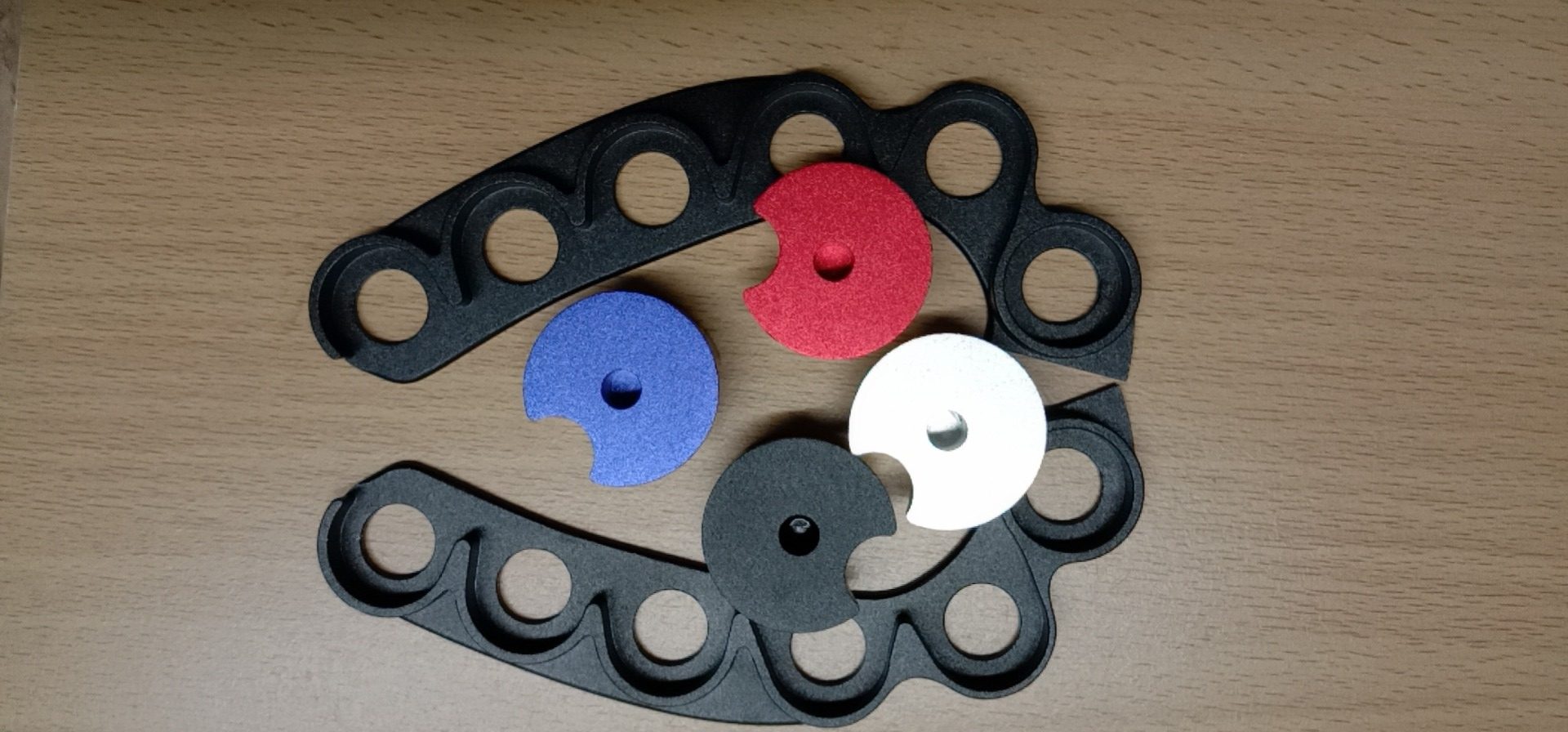

Anodized CNC Machining Button Guard and Knobs

- Material: Aluminum alloy 6061

- Size: 128*64*7 mm; 30*28*14 mm

- Process: CNC turning and CNC milling

- Surface treatment: Sandblasted;Clear anodized; Red anodized; Blue anodized; Black anodized

Why Do We Need Anodized CNC Machining Button Guards and Knobs?

There are a few reasons why someone might use anodized CNC machined button guards and knobs:

- Durability: CNC machining creates parts from solid metal, typically aluminum. Aluminum is strong and lightweight, but it can be scratched or dented if not protected. Anodizing creates a hard, oxide layer on the surface of the aluminum that makes it more resistant to scratches, corrosion, and wear. This is especially important for buttons and knobs that are frequently used or exposed to harsh environments.

- Precision: CNC machining allows for the very precise creation of parts, down to very small tolerances. This is important for buttons and knobs that need to function smoothly and accurately. A slight imperfection could cause a button to stick or a knob to wobble.

- Aesthetics: Anodizing comes in a wide variety of colors, which can be used to customize the look of buttons and knobs. This can be important for applications where appearance is important, such as in high-end audio equipment or gaming controllers.

- Improved Grip: Some anodized finishes can create a grippier surface than bare aluminum, which can be helpful for applications where users need to be able to operate buttons and knobs precisely, even with wet or sweaty hands.

What Colors Are Available for the Anodizing?

The range of colors available for anodizing is quite vast, though there can be some variation depending on the anodized and the specific process used. Here’s a breakdown of what to expect:

- Standard Colors: Many anodizers offer a set of standard colors that are readily available and often more affordable. These typically include colors like black, bronze (light, medium, and statuary), and silver.

- Custom Colors: For a wider variety of hues, anodizes can create custom colors. This might involve adjusting the anodizing parameters or using dyes. However, this customization often comes with additional setup charges.

- General Color Palette: Even without custom options, the range of achievable colors with anodizing includes:

- Black

- Bronze (various shades)

- Gold

- Blue

- Green

- Red

- Copper

Why Choose JTR?

Chongqing Jin Te Rui Machine Co., Ltd. offers professional mass manufacturing and rapid prototyping services, such as CNC machining, die casting, 3D printing, rapid tooling and injection molding, plastic and aluminum extrusion, sheet metal prototyping, and new product design and development integration. We can quickly implement your design using our excellent manufacturing solutions, which can take only hours. This allows you to thoroughly test the product and make any necessary changes to improve the design before it goes into full production.