CNC Milling Titanium Parts

The rich potential of Titanium as a material is now fully recognized, and the scope of its application is expanding every day. Since it’s a perfect material for the machine in CNC milling, CNC milling titanium part becomes an excellent character in many fields like aerospace, general industries, construction, four – and two-wheeled vehicles and products for daily use, etc.

What’s more, CNC Milling Titanium can be divided into a selection series according to its grades and alloy types to different applications. The following are titanium’s different properties and applications.

Features and Applications of Different Titanium

Ta1 and Ta2: Titanium content is in a high proportion, its mechanical properties, and chemical properties are similar to stainless steel, the strength is not as high as titanium alloys, has good plasticity, it is easy to process and form, the stamping and welding performance is good, corrosion resistance, oxidation resistance is stronger than stainless steel, but the heat resistance is lower than it.

Mainly used for stamping parts, corrosion-resistant structural parts with working temperature below 350℃ and low stress but requiring high plasticities, such as aircraft skeletons, ship pipes, and ion pumps. The industry generally requires high formation to use Tal, The most widely used is Ta2.

Tc4: Good comprehensive mechanical properties, most of which can be strengthened by heat treatment, forging, stamping and welding, high room temperature strength, good heat resistance in the temperature range of 150-500 ℃, good low-temperature toughness, and corrosion resistance, Tc4 is the most widely used alloy material among Tc series.

Long-term used parts below 400℃, low-temperature parts such as containers and pumps, military parts, easy-to-use equipment, outdoor parts, and parts with high strength requirements.

About the CNC Milling Material – Titanium

Titanium Grade 5 is the strongest titanium alloy with great deterioration resistance and the ability to be welded. Titanium might be chosen over various other materials such as steel due to its capability to withstand high and also subzero temperatures. Typical use situations include aerospace fasteners, wind turbine blades, engine elements, sports devices as well as marine applications.

The density of titanium is 4.506-4.516 grams per cubic centimeter (20°C), which is higher than that of aluminum and lower than that of iron, copper, and nickel. But the specific strength is at the top of the metal. Melting point 1668±4℃, latent heat of fusion 3.7-5.0kcal/g atom, boiling point 3260±20℃, latent heat of vaporization 102.5-112.5kcal/g atom, critical temperature 4350℃, critical pressure 1130 atmospheres.

Titanium has poor thermal conductivity and electrical conductivity, similar to or slightly lower than stainless steel, titanium has superconductivity, and the superconducting critical temperature of pure titanium is 0.38-0.4K. At 25°C, the heat capacity of titanium is 0.126 cal/g-atom·degree, the enthalpy is 1149 cal/g-atom·degree, and the entropy is 7.33 cal/g-atom·degree. Titanium is a paramagnetic substance with a magnetic permeability of 1.00004.

Titanium has plasticity, the elongation rate of high-purity titanium can reach 50-60%, and the section shrinkage rate can reach 70-80%, but its strength is low, and it is not suitable for structural materials. The existence of impurities in titanium has a great influence on its mechanical properties, especially interstitial impurities (oxygen, nitrogen, carbon) can greatly improve the strength of titanium and significantly reduce its plasticity. The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements.

| Yield Strength | Elongation at Break | Hardness | Density | Max Temp |

| 120,000 PSI | 10% | Rockwell C30 | 0.16 lbs / cu. in | 3000°F |

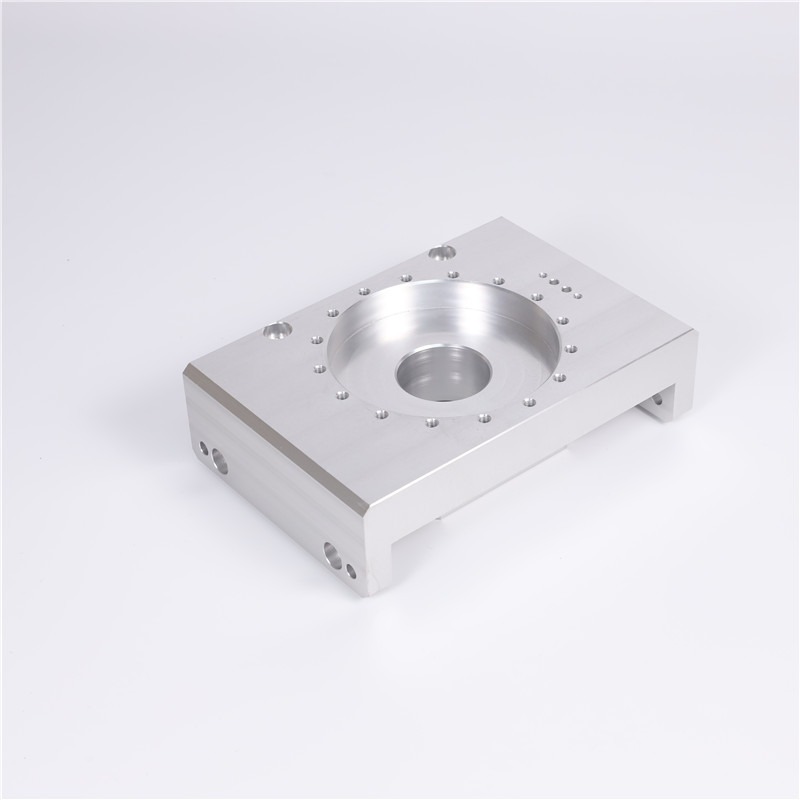

Why Choose Our CNC Milling Titanium Service?

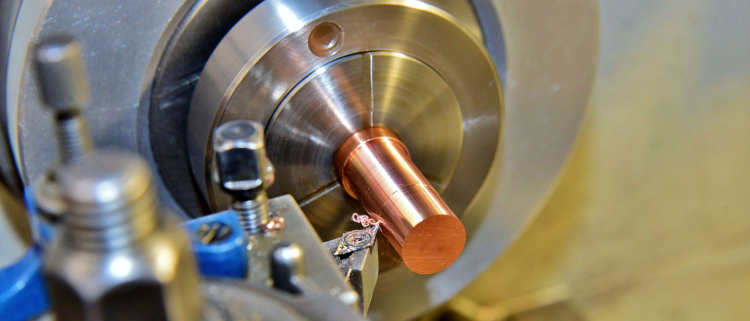

- Equipped with more than 40 precision CNC processing equipment of various types, such as three-axis, four-axis, and five-axis machining centers, drilling and tapping centers, etc.

- Fast turnaround, standard packaging, and on-time delivery.

- ISO9001:ISO9001:2008 and TS16949 quality system certification in 2015, and obtained the IATF quality system transition audit certification in 2017.

- Exact specification, dimensions of drilled parts consistent with custom design.

- Precision titanium drilling with dimensional stability and tight tolerance.

- Wide applications include medical, aerospace, airplane, engine, military, etc.