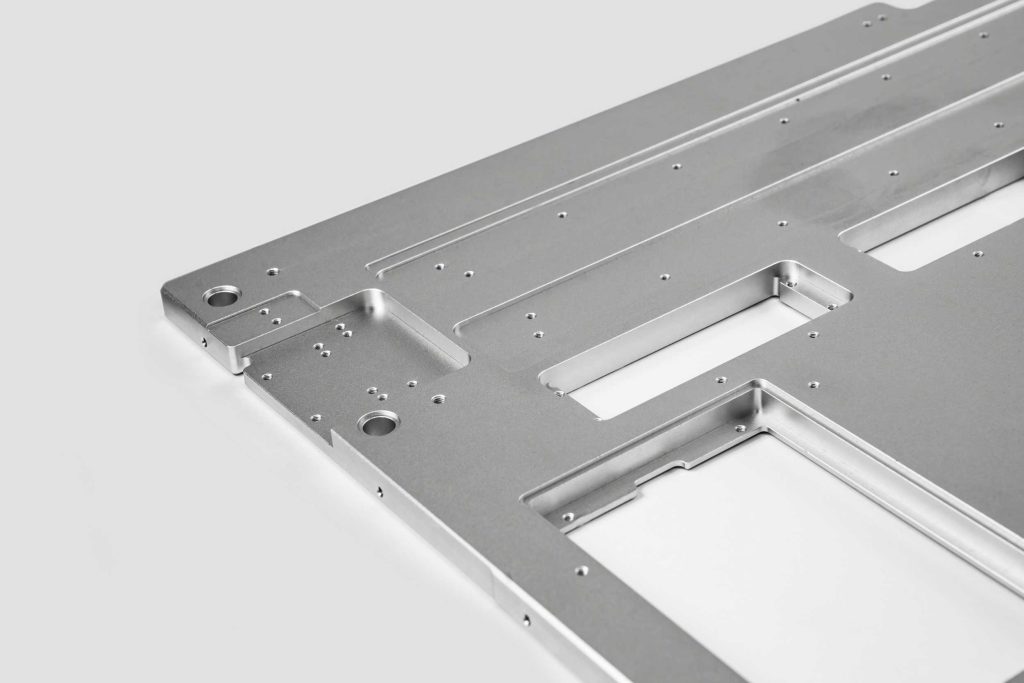

CNC Turning Aluminum Parts

CNC Turning in Aluminum – China High-Quality CNC Machining Aluminum Parts

Aluminum is the most widely used metal material among non-ferrous metals, and its application range is still expanding. There are many kinds of aluminum products produced using aluminum, more than 700,000 types according to statistics. Various industries such as construction and decoration, transportation, and aerospace have different needs. For CNC Turning, aluminum is also an indispensable material. Because aluminum owns character as lightweight, non-magnetic, silver-colored, it can be formed into almost any shape, which enlarges the creativity of CNC turning, making more possibilities.

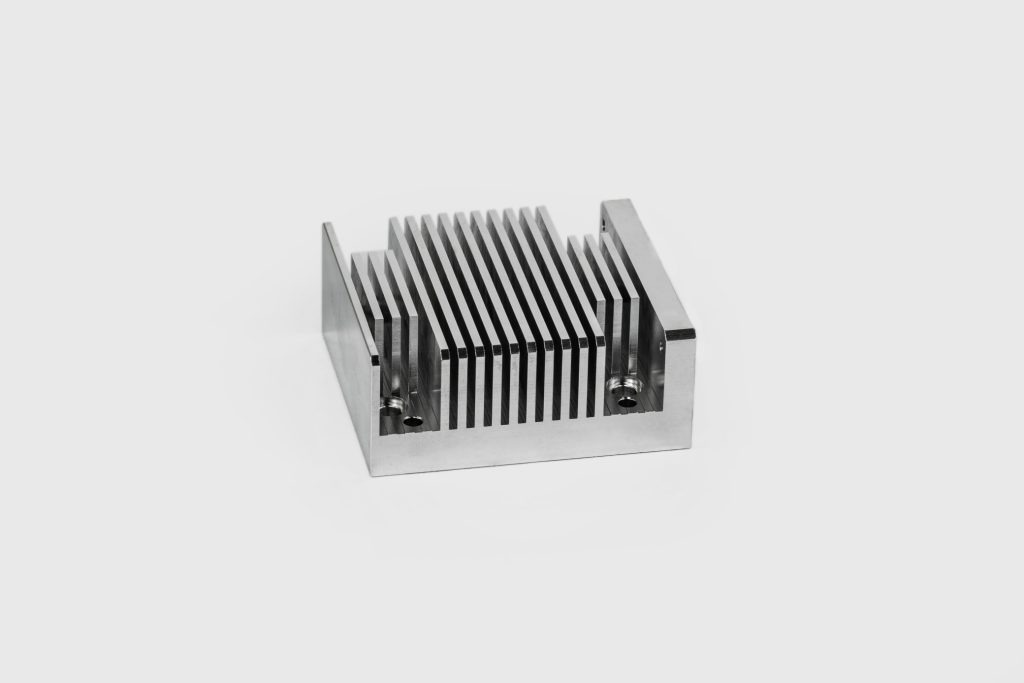

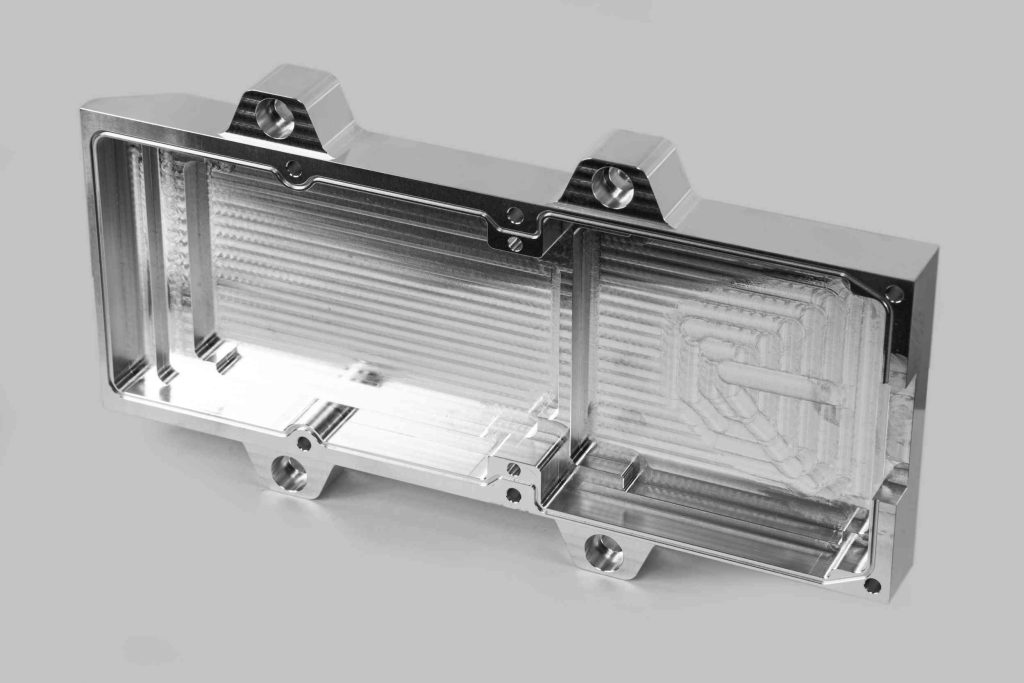

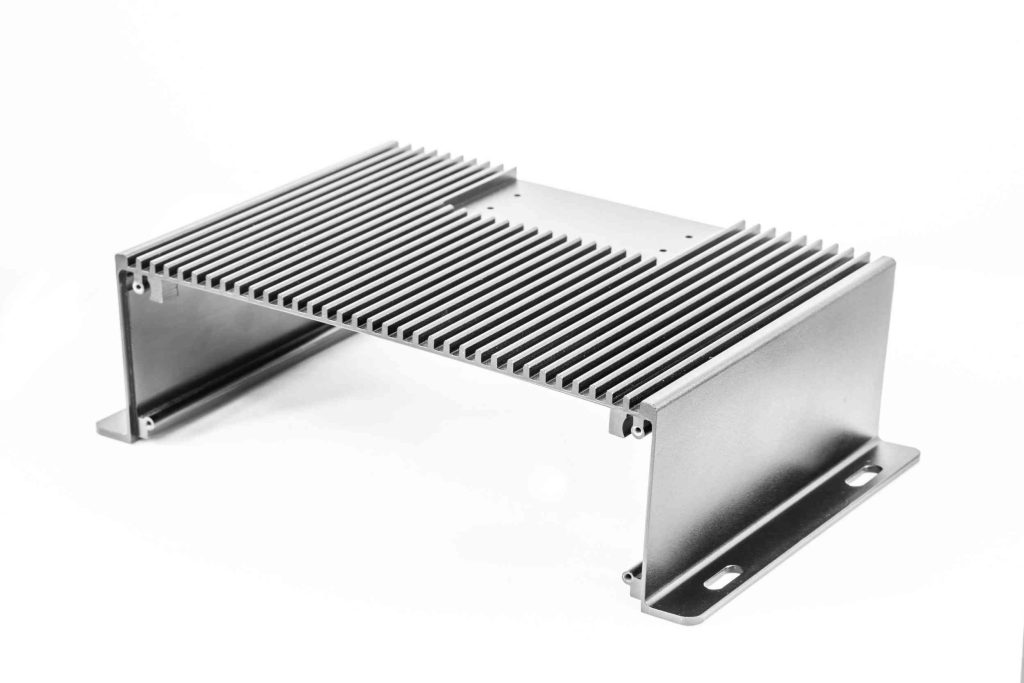

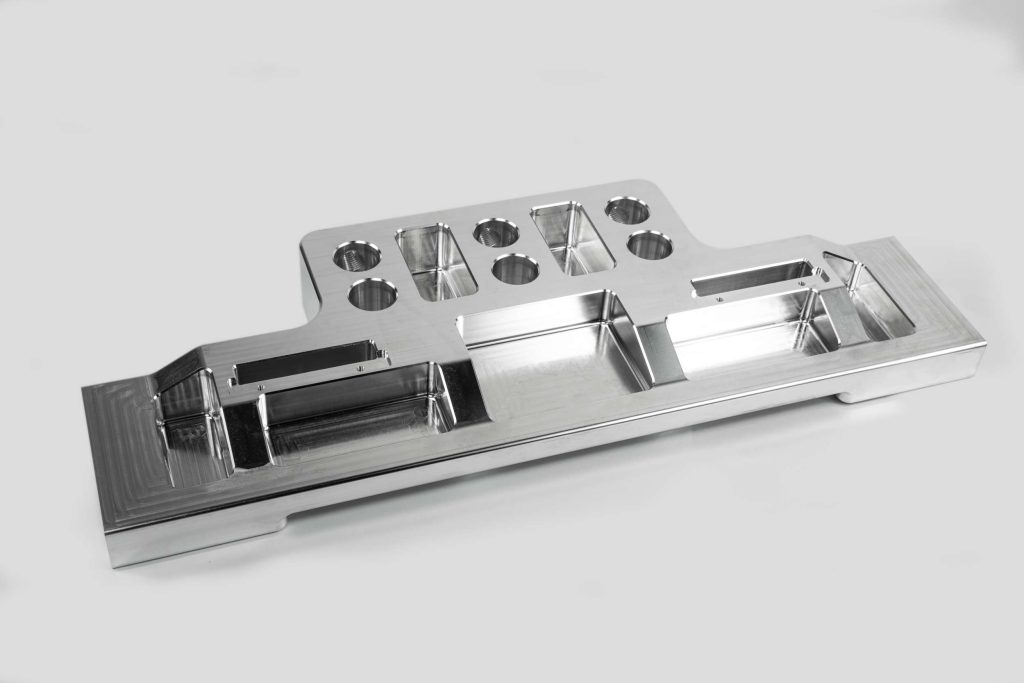

JTR CNC Turning Aluminum Parts

CNC turning for Aluminum is now widely used in many applications, and then there is a developing need for CNC turning aluminum parts, JTR is one of China’s Top Aluminum CNC turning services suppliers. Our CNC center team is working to satisfy our customers’ needs. No matter how complicated the aluminum part will be, we always give our customers the best quality of products in the market.

The advantages and characteristics of aluminum are as follows:

1. Low density. The density of aluminum is about 2.7g/cm3. Its density is only 1/3 of that of iron or copper.

2. High plasticity. Aluminum has good ductility and can be made into various products through pressure processing methods such as extrusion and stretching.

3. Corrosion resistance. Aluminum is a highly negatively charged metal. A protective oxide film will be formed on the surface under natural conditions or anodic oxidation, which has much better corrosion resistance than steel.

4. Easy to strengthen. The strength of pure aluminum is not high, but its strength can be improved by anodizing.

5. Easy surface treatment. Surface treatment can further improve or change the surface properties of aluminum. The aluminum anodizing process is quite mature and stable in operation and has been widely used in the processing of aluminum products.

6. Good conductivity, Easy to recycle.

CNC Turning Materials for Aluminum Parts

Aluminum 6061

The standard alloy used for our machining services is Aluminum 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable.

| Tensile Strength, Yield (MPa) | Young’s Modulus (E) | Density (ρ) | Specific Heat Capacity (c) | Elongation (ε) at break |

| 124–290 MPa (18.0–42.1 ksi) | 68 GPa (9,900 ksi) | 2.70 g/cm3 | 897 J/(kg·K) | 12–25% |

Aluminum 7075

7075 aluminum is often a hard, high-strength alternative to 6061 aluminum. It is often used for parts in high-stress applications, and 7075 aluminum is also corrosion-resistant, non-magnetic, and heat-treatable.

| Density (ρ) | Young’s modulus (E) | Tensile Strength (σt) | Elongation (ε) at break | Maximum Yield Strength |

| 2.81 g/cc (0.102 lb/cu in) | 71.7 GPa (10,400 ksi) | 572 MPa (83.0 ksi) | 11% | 280 MPa (41 ksi) |

Aluminum 2024

2024 aluminum alloy is an aluminum alloy with copper as the main alloying element. It is used in applications requiring a high strength-to-weight ratio as well as good fatigue resistance. Although 2024 aluminum is not as strong as 7075 aluminum, it is often used when a high strength-to-weight ratio is required. It is heat treatable and non-magnetic.

| Density (ρ) | Electrical Conductivity | Young’s Modulus (E) | Elongation (ε) at break | |

| 2.78 g/cm3 (0.1 lb/in3) | 30% | 73 GPa (10.6 Msi) | 10–25% |

Aluminum 5052

5052 aluminum is the easiest aluminum to weld and is extremely resistant to salt spray and salt water. It is easy to form, heat treatable, and non-magnetic. The exceptional corrosion resistance of 5052 alloys against seawater and salt spray makes it a primary candidate for the failure-sensitive large marine structures, like tanks of liquefied natural gas tankers.

Typical applications of 5052 aluminum alloy include marine, aircraft, architecture, general sheet metal work, heat exchangers, fuel lines and tanks, flooring panels, streetlights, appliances, rivets, and wire.

| Density (ρ) | Volume Resistivity (ρ) | Young’s Modulus (E) | Elongation (ε) at break | Tensile Strength, Yield (MPa) |

| 2.68 g/cm3 | 49.3-49.9 nOhm*m | 69.3 GPa | 7-27% | 195–290 MPa (28.3–42.1 ksi) |

Aluminum 6063

AA 6063 is an aluminum alloy, with magnesium and silicon as the alloying elements. 6063 aluminum is more resistant to corrosion and molding than 6061 aluminum. It is not suitable for high-strength applications but can be used for exterior railings and decorative trim. The benefit of CNC machined 6.63 aluminum is that it is heat treatable and non-magnetic.

| Density (ρ) | Young’s modulus (E) | Tensile Strength (σt) | Elongation (ε) at break | Specific Heat Capacity (c) |

| 2.69 g/cm3 | 68.3 GPa (9,910 ksi) | 145–186 MPa (21.0–27.0 ksi) | 18–33% | 900 J/kg*K |