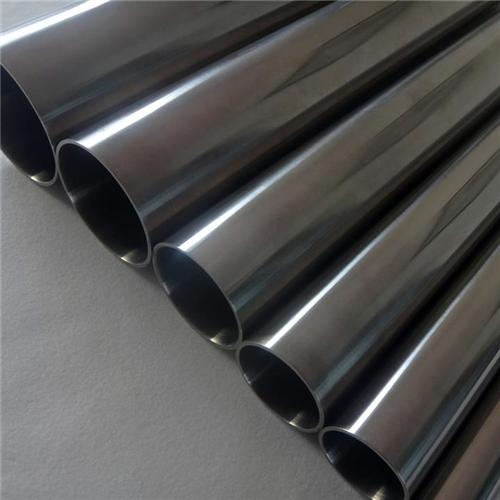

CNC Turning Stainless Steel Parts

Stainless steel has always been known as a material with strong corrosion resistance, and it is one of the most popular choices for building materials. For centuries, stainless steel has been used in architecture, engineering, landscape, interior, and marine architecture. Robust, versatile, and recyclable. Here is a brief overview of stainless steel, its properties, and the advantages derived from it. Stainless steel is also frequently used in CNC machining. Because of its high-temperature resistance and corrosion resistance, stainless steel CNC machining has become an indispensable role in CNC machining.

CNC Turning Materials for Stainless Steel Parts

Stainless steel 303

SS301: Low content of Cr and Ni, the tensile strength and hardness are increased during cold working. non-magnetic, but it is magnetic after cold working.

| Tensile Strength, Yield (MPa) | Hardness | Density (ρ) | Maximum Temp | Elongation (ε) at break |

| 35,000 psi | Rockwell B95 | 0.29 lbs / cu. in. | 2550° F | 42.5% |

Stainless steel 304L

The lower carbon content of 304L stainless steel helps reduce/eliminate carbide precipitation during welding. This allows 304L stainless steel to be “welded” even in severely corrosive environments. Using 304L eliminates the need to anneal welded joints before using the full metal form, saving time and effort.

| Tensile Strength, Yield (MPa) | Hardness | Density (ρ) | Maximum Temp | Elongation (ε) at break |

| 30,000 psi | Rockwell B80 (medium) | 0.29 lbs / cu. in. | 1500° F | 50% |

Stainless steel 316L

Stainless steel 316L grade stainless steel, sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304/A2 stainless steel.

| Tensile Strength, Yield (MPa) | Hardness | Density (ρ) | Maximum Temp | Elongation (ε) at break |

| 30,000 psi | Rockwell B95 | 0.29 lbs / cu. in. | 1500° F | 39% |

Stainless steel 416

Alloy 416 is a martensitic, free-machining, chromium steel alloy generally considered the first free-machining stainless steel. It has the highest machinability of all stainless steel, approximately 85% of free-cutting carbon steel. Martensitic stainless steels are designed to be heat-hardenable and corrosion-resistant. Although Alloy 416 and other martensitic stainless steels are not as corrosion resistant as austenitic or ferritic stainless steels, they still exhibit good corrosion and oxidation resistance and high strength in the hardened and tempered condition. Alloy 416HT is easy to machine, always magnetic, and has low friction properties that reduce wear and seizing.

| Tensile Strength, Yield (MPa) | Hardness | Density (ρ) | Maximum Temp | Elongation (ε) at break |

| 75,000 psi | Rockwell B80 | 0.28 lbs / cu. in. | 1200° F | 22.5% |

Stainless steel 440C

Grade 440C stainless steel is a high carbon martensitic stainless steel. High strength, moderate corrosion resistance, good hardness, and wear resistance. Grade 440C achieves the highest strength, hardness, and wear resistance of any stainless steel alloy after heat treatment. Its very high carbon content is responsible for these properties, making 440C particularly suitable for applications such as ball bearings and valve parts.

| Tensile Strength, Yield (MPa) | Hardness | Density (ρ) | Maximum Temp | Elongation (ε) at break |

| 110,000 psi | Rockwell C20 | 0.28 lbs / cu. in. | 800° F | 8% |

China’s top precision CNC turning stainless steel service provider

JTR is China’s top CNC turning stainless steel parts processing expert. We have first-class CNC turning technical services and advanced machinery and equipment (including), which can provide you with different design suggestions and solutions to problems. CNC turning parts can be used in many fields, such as automobiles, molds, shipbuilding, aerospace, and engineering machinery. If you are looking for a CNC turning service, please contact us.

Applications of CNC turning stainless steel parts

- Culinary uses

- Kitchen sinks

- Cutlery

- Cookware

- Automotive and

- aerospace

- applications Autobodies

- Rail cars

- Aircraft

- Architecture (pictured above: Chrysler Building)

- Bridges

- Monuments and sculptures

- Airport roofs

- Surgical tools and medical equipment

- Hemostats

- Surgical implants

- Temporary crowns (dentistry)