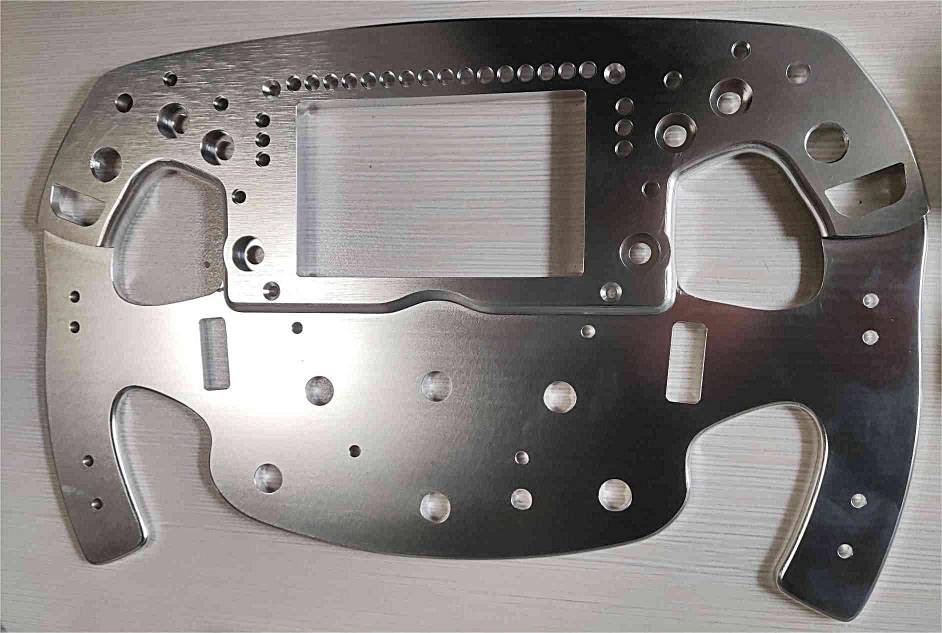

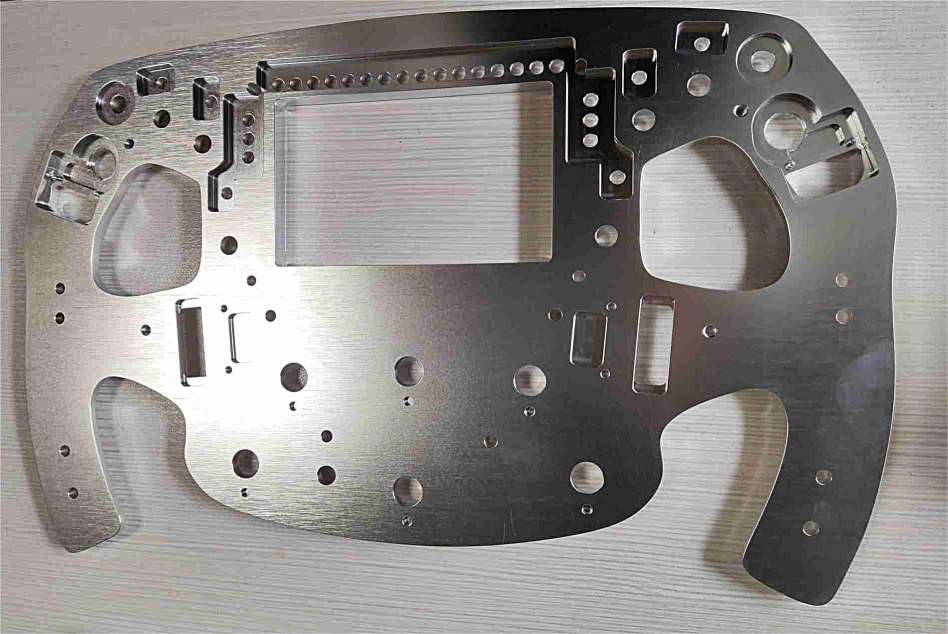

CNC Milling Aluminum Plate without Any Finish

- Material: AL 6061

- Size: 187.278X8.002X297.354 mm

- Process: CNC milling

- Surface treatment: machined surface

What are the Applications of CNC Milling Aluminum Plate without Any Finish?

CNC milling aluminum plates without any finish can find application in various industries and contexts:

- Prototype Development: In engineering, aerospace, automotive, and product design industries, aluminum plates are often used for prototyping due to their favorable properties like machinability and strength-to-weight ratio. CNC milling allows for precise shaping of prototypes.

- Functional Components: Aluminum plates machined via CNC milling can be used for creating functional components in machinery, equipment, or devices where strength, lightweight, and precision are essential.

- Structural Parts: In construction, CNC-milled aluminum plates can be used for structural components, especially in lightweight structures where corrosion resistance and durability are required.

- Heat Sinks: Aluminum’s excellent thermal conductivity makes it ideal for heat sinks in electronic devices. CNC milling allows for intricate designs and precise fabrication of heat sink structures to dissipate heat effectively.

- Fixturing and Jigs: Manufacturing processes often require custom fixtures and jigs to hold workpieces in place during machining. CNC milling aluminum plates can produce these fixtures accurately, ensuring repeatability and precision in production processes.

- Artistic Creations: Artists and designers may use CNC milling on aluminum plates for creating sculptures, decorative elements, or artistic installations due to its versatility in shaping complex designs.

- Educational Purposes: CNC milling aluminum plates are used in educational institutions to teach students about machining processes, CAD/CAM design, and precision engineering.

- Custom Components: CNC milling allows for the production of custom components tailored to specific requirements, whether it’s for hobbyists, DIY projects, or specialized applications.

- Aircraft and Aerospace: Aluminum is widely used in the aerospace industry due to its lightweight properties. CNC-milled aluminum plates can be used for aircraft components, structural elements, and aerospace parts where precise machining is crucial for safety and performance.

- Automotive Parts: Aluminum is increasingly used in automotive manufacturing for its weight-saving properties. CNC milling aluminum plates can produce various automotive parts, such as engine components, brackets, and chassis elements.

In all these applications, the absence of a finish on CNC-milled aluminum plates might be acceptable depending on the specific requirements of the project. However, if corrosion resistance or aesthetics are important, post-processing such as anodizing or powder coating may be necessary.

Why Choose 6061 Aluminum for CNC Milling?

6061 aluminum is a popular choice for CNC milling for several reasons:

- Machinability: 6061 aluminum has excellent machinability, making it easy to work with using CNC milling machines. It cuts cleanly and smoothly, reducing the wear on cutting tools and ensuring precise machining.

- Strength and Durability: 6061 aluminum is known for its high strength-to-weight ratio, making it suitable for applications where strength and durability are important, such as in aerospace, automotive, and structural components.

- Corrosion Resistance: This alloy offers good resistance to corrosion, which is crucial for applications exposed to harsh environments or outdoor use.

- Weldability: 6061 aluminum can be easily welded using various techniques, allowing for the fabrication of complex structures and assemblies.

- Anodizing Ability: It responds well to various finishing techniques, including anodizing, which enhances its appearance, improves corrosion resistance, and provides additional surface hardness.

- Availability: 6061 aluminum is widely available and relatively inexpensive compared to some other alloys, making it a cost-effective choice for many machining projects.

Overall, the combination of machinability, strength, durability, corrosion resistance, weldability, and availability makes 6061 aluminum a preferred material for CNC milling in numerous industries.