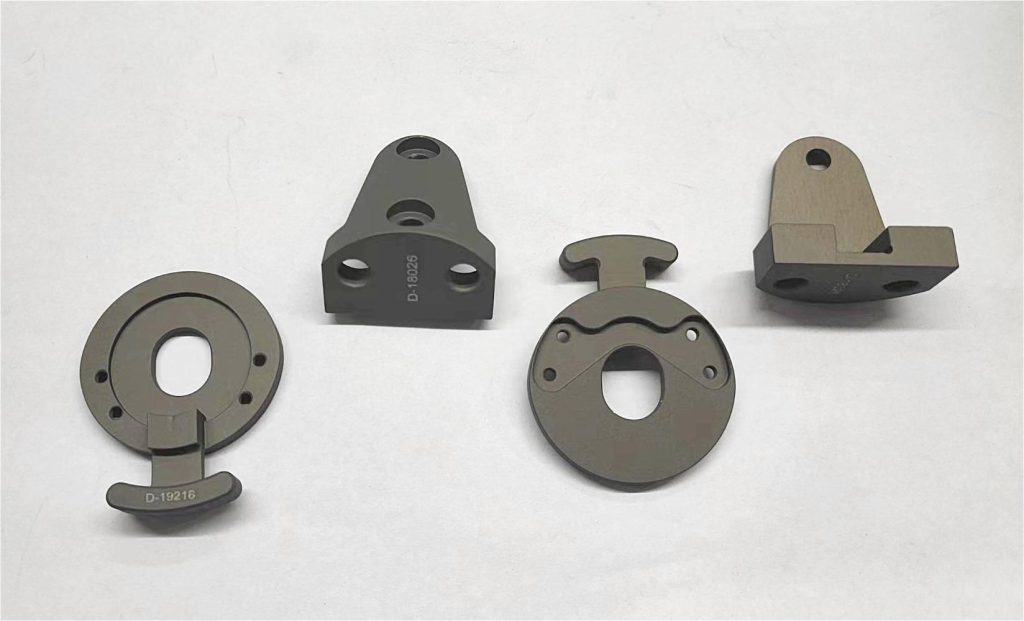

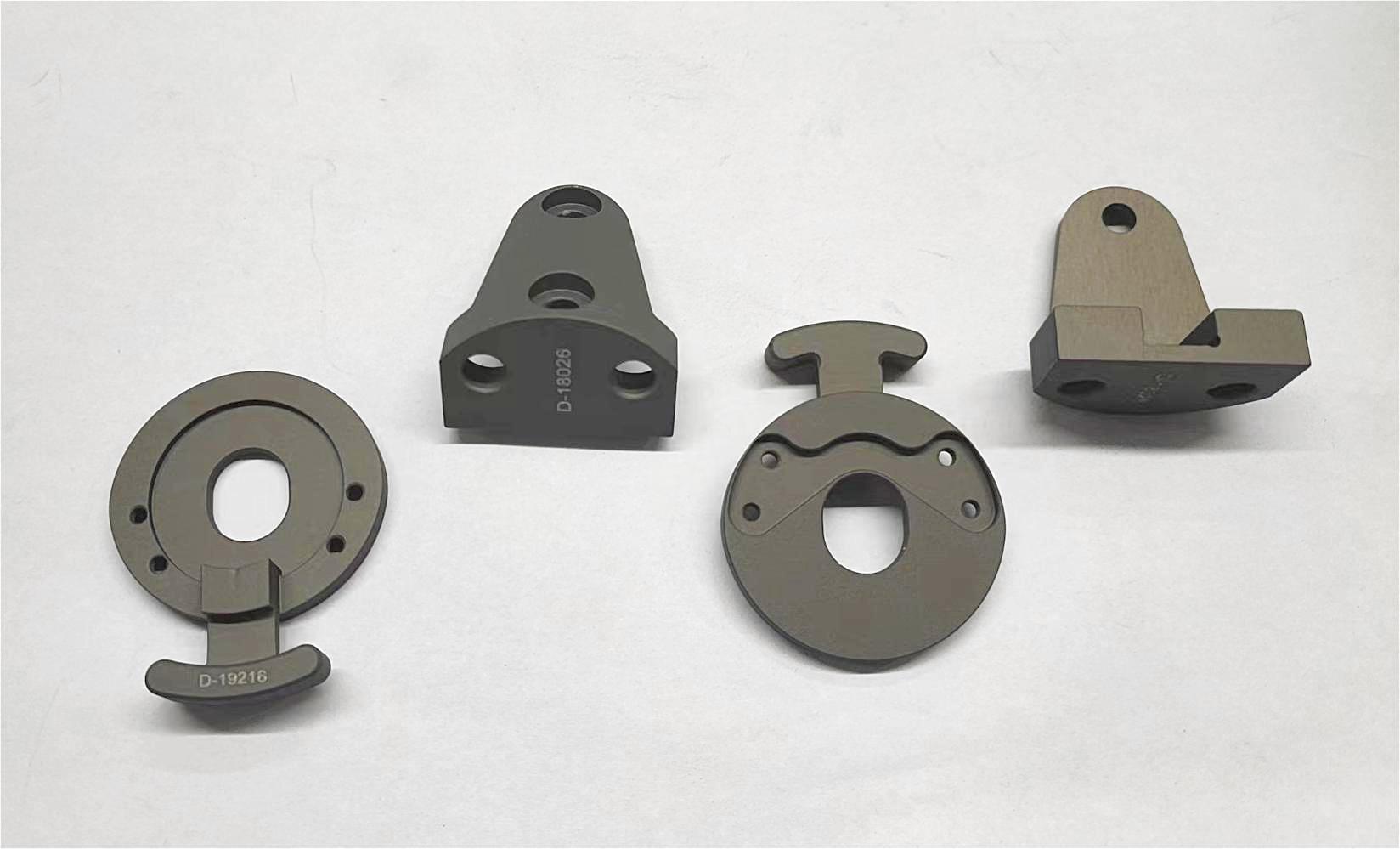

Hard Anodized Aluminum CNC Machining Lock Plate

- Material: Aluminum alloy 6061

- Size: 52.75×42.31x12mm

- Process: CNC milling

- Surface treatment: Sand blasted+Natural hard anodized

What are the Benefits of Hard Anodizing?

Hard anodizing is a specialized anodizing process that produces a thick, dense, and durable oxide layer on the surface of metals, typically aluminum. Here are some of the benefits of hard anodizing:

- Increased Hardness: Hard anodizing significantly increases the hardness of the metal surface, making it more resistant to wear, abrasion, and scratching. This makes it suitable for applications where durability is crucial, such as in aerospace components, automotive parts, and industrial machinery.

- Improved Wear Resistance: The hard oxide layer formed through anodizing enhances the wear resistance of the metal surface, prolonging the lifespan of the component and reducing maintenance requirements.

- Corrosion Resistance: Hard anodizing provides excellent corrosion resistance by creating a barrier between the metal substrate and the environment. This makes the treated metal suitable for use in harsh environments where exposure to moisture, chemicals, or other corrosive substances is a concern.

- Electrical Insulation: The thick oxide layer formed during hard anodizing acts as an electrical insulator, which can be advantageous in electronic applications where electrical conductivity needs to be controlled or minimized.

- Thermal Insulation: Hard anodizing can also provide a degree of thermal insulation, which may be beneficial in applications where temperature control is important or where thermal barriers are required.

- Aesthetic Enhancement: Hard anodizing can be performed in a variety of colors, offering aesthetic options for applications where appearance matters. Additionally, the process can be used to create a uniform, attractive finish that enhances the overall appearance of the metal surface.

- Dimensional Stability: Unlike some coating processes, hard anodizing typically does not significantly alter the dimensions of the treated component, preserving its precise tolerances and dimensional accuracy.

- Environmental Friendliness: Anodizing is an environmentally friendly process that does not involve heavy metals or toxic chemicals. It generates minimal waste, and the anodized metal can often be recycled at the end of its useful life.

Overall, hard anodizing offers a combination of mechanical, chemical, electrical, and thermal properties that make it a popular choice for a wide range of industrial applications where enhanced performance and durability are required.

Why Choose JTR for Anodizing?

Chongqing Jin Te Rui Machine Co., Ltd. offers professional mass manufacturing such as CNC machining, die casting, and injection molding. We also provide almost all surface finishing solutions to almost all materials, no matter how they are processed. Our processes include adding, altering, removing and reshaping the material, meeting the needs for all surface finishing options. Our Strong production capacity makes the shortest lead times and quality guaranteed. Feel free to get inquiries.