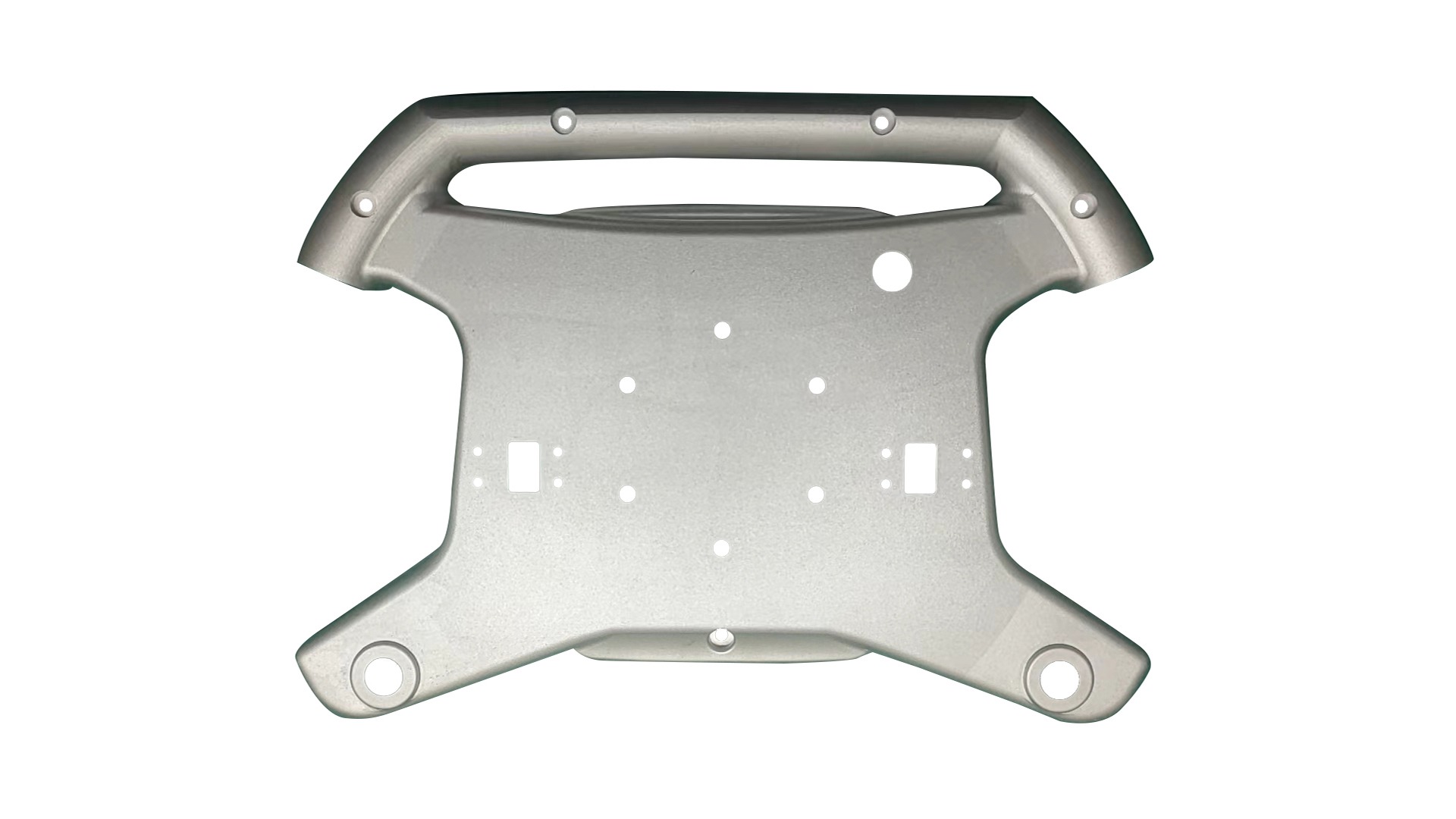

Sandblasted CNC Milled Aluminum Parts

- Material: AL6061-T6

- Size: 281*205*21mm

- Process: CNC milling

- Surface treatment: Sandblasted

What Are the Advantages of Sandblasted CNC Milled Aluminum Parts?

Sandblasted CNC-milled aluminum parts offer several advantages over untreated or otherwise finished CNC-machined aluminum:

- Enhanced Appearance: Sandblasting creates a uniform matte or satin finish that can hide minor imperfections from the CNC machining process, resulting in a more aesthetically pleasing look.

- Increased Grip: The textured surface created by sandblasting improves grip, making the parts easier to handle and less slippery, especially important for parts that will be touched frequently.

- Preparation for Adhesion: The roughened surface from sandblasting provides a good mechanical bond for paint, adhesives, or other coatings, ensuring they adhere better and last longer.

- Fast and Efficient Cleaning: Sandblasting effectively removes any contaminants or residues left behind from the CNC machining process, creating a clean surface for further processing or use.

- Versatility: Sandblasting can be used on a wide variety of CNC-machined aluminum parts regardless of complexity.

- Potential Time Savings: Because sandblasting can clean and improve surface texture in one step, it can streamline the finishing process compared to multi-step techniques.

How Does the Sandblasting Affect the Size of the Part?

Sandblasting can affect the size of a CNC-milled aluminum part, but it’s usually a minor effect. Here’s why:

Sandblasting works by forcefully propelling abrasive material against the surface of the part. This process removes a small amount of material to achieve the desired finish. However, the amount of material removed is typically very small, often measured in thousandths of an inch ( microns). This is because sandblasting is primarily used for cleaning and texturing the surface, not for significant material removal. Experienced operators can control the blasting pressure, media type, and blasting time to minimize material removal and ensure the part stays within dimensional tolerances.

When Size Matters:

- Critical Dimensions: If your application requires very tight tolerances, it’s important to factor in the potential size reduction from sandblasting. You can discuss this with your CNC machining service to ensure they leave enough material for the final sandblasting step.

- Alternatives for Tight Tolerances: In some cases, if dimensional precision is paramount, other finishing techniques like polishing or anodizing might be a better option as they have minimal impact on part size.

Overall, sandblasting is a great finishing technique for CNC-milled aluminum parts, but be mindful of potential minimal size reduction if your application has strict dimensional requirements. Discuss this with your CNC service to ensure the parts meet your needs.

Why Choose Us?

We are a professional manufacturer dedicated to offering high-quality rapid prototyping and mass production services. We offer high-quality manufacturing solutions that can help you realize your design in just a few hours. This enables you to conduct rigorous product testing and make all necessary changes to perfect the design before moving into full production. If you choose us, we will provide you with excellent customer service.