Anodizing is a versatile and widely used surface treatment process that enhances the durability, corrosion resistance, and aesthetic appeal of various metal products. This electrochemical process creates an oxide layer on the surface of metals, primarily aluminum, through controlled oxidation. In this article, we will delve into the world of anodizing, exploring the different types of anodizing and the materials involved in this essential industrial process.

What are the Types of Anodizing?

There are several types of anodizing processes, each with its characteristics and applications. The three primary types of anodizing are:

Type 1: Chromic Acid Anodizing (CAA)

- Process: This anodizing process uses chromic acid (often a mixture of chromic acid and sulfuric acid) as the electrolyte.

- Characteristics: CAA creates a thin and highly corrosion-resistant oxide layer on the surface of the metal. It results in minimal dimensional change, making it suitable for precision components.

- Applications: Commonly used in the aerospace industry for components where precise tolerances are critical, such as aircraft parts.

Type 2: Sulfuric Acid Anodizing (SAA)

- Process: Sulfuric acid anodizing is the most common method for anodizing aluminum.

- Characteristics: This process results in a thicker and more porous oxide layer compared to chromic acid anodizing. It provides an excellent base for coloring and dye absorption.

- Applications: Widely used in various industries, including automotive, architectural, consumer electronics, and more, due to its versatility and ability to produce aesthetically pleasing finishes.

Type 3: Hardcoat Anodizing (Hard Anodizing)

- Process: Hardcoat anodizing involves using a more concentrated sulfuric acid solution at lower temperatures than Type II anodizing.

- Characteristics: It creates a thicker, harder, and wear-resistant oxide layer on the surface of the metal. The resulting oxide layer is typically thicker than that produced by Type II anodizing.

- Applications: Ideal for components subjected to heavy wear and abrasion, such as pistons, cylinders, hydraulic components, and military hardware.

These three types of anodizing processes are the most common and widely used. The choice of which type to use depends on the specific properties and characteristics desired for the finished product. Each type of anodizing offers unique advantages and is suited to different applications, ranging from precision aerospace components to decorative architectural elements.

What are the Materials Used in Anodizing?

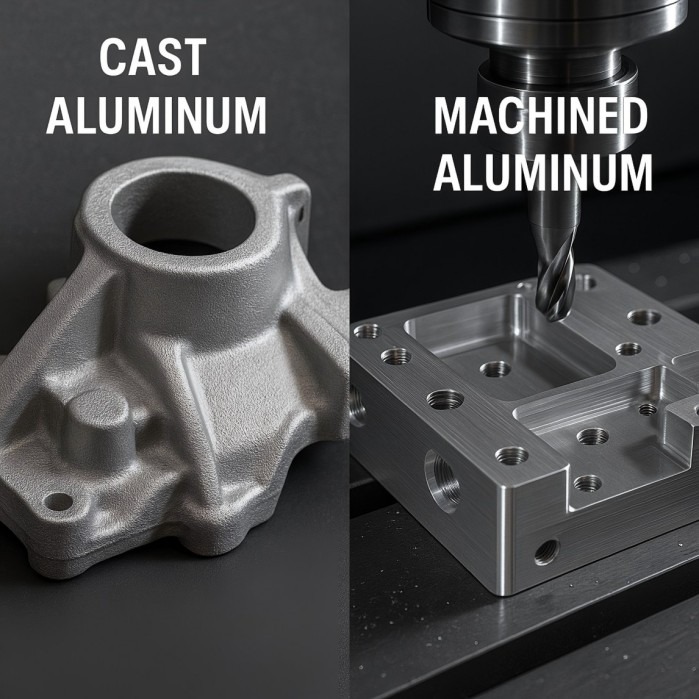

The primary material used in the anodizing process is aluminum and its various alloys. Anodizing is most commonly associated with aluminum due to its unique properties and the effectiveness of the anodizing process in enhancing those properties. However, other materials can also undergo similar processes, albeit with variations. Here are some materials that can be anodized:

- Aluminum and Aluminum Alloys: Anodizing is most commonly applied to aluminum and its alloys. Various aluminum alloys, such as 6061, 7075, and others, can undergo anodizing to enhance their properties and appearance.

- Titanium: Titanium anodizing is a process similar to aluminum anodizing, where a titanium oxide layer is formed on the surface. This process is often used for applications that require high corrosion resistance, such as medical implants and aerospace components.

- Magnesium: Although less common than aluminum and titanium anodizing, magnesium can also be anodized to improve its corrosion resistance and appearance. Anodized magnesium is used in aerospace and automotive applications.

- Niobium: Niobium is a rare material that can undergo a specialized anodizing process to create vibrant and long-lasting colors on its surface. It is commonly used in jewelry and art.

- Zinc: Zinc anodizing, also known as zinc plating or zinc passivation, is used to improve the corrosion resistance of zinc-coated steel parts. It is commonly used in the automotive industry for components like bolts and fasteners.

- Tantalum: Tantalum can undergo anodizing to create a stable oxide layer on its surface, which enhances its corrosion resistance. Tantalum anodizing is often used in chemical processing equipment.

- Magnesium Alloys: Similar to pure magnesium, some magnesium alloys can be anodized for corrosion protection and improved surface properties.

It’s important to note that the specific anodizing processes and conditions can vary depending on the material being anodized. While aluminum anodizing is the most prevalent and well-documented, other materials may require unique procedures to achieve the desired results. The choice of material for anodizing depends on the intended application and the properties sought after the anodizing process.

What are the Applications of Anodizing Aluminum?

Anodizing is a versatile surface treatment process with a wide range of applications across various industries. Its ability to enhance the properties and appearance of materials, particularly aluminum, makes it valuable in numerous sectors. Here are some common applications of anodizing aluminum:

- Aerospace Industry: Anodized aluminum is extensively used in the aerospace sector due to its lightweight nature, corrosion resistance, and enhanced strength. Aircraft components, including structural parts, engine components, and fasteners, often undergo anodizing to ensure durability and performance in challenging environments.

- Automotive Industry: Anodized aluminum is found in various automotive components, such as wheels, trim, and engine parts. It provides an attractive finish, corrosion protection, and improved wear resistance, making it crucial for both aesthetics and functionality in the automotive world.

- Architectural and Building Materials: Anodized aluminum is a preferred choice for architectural elements like window frames, curtain walls, facades, and handrails. It offers an appealing finish, corrosion resistance, and the ability to withstand harsh weather conditions, making it suitable for both interior and exterior applications.

- Consumer Electronics: The sleek and vibrant appearance of anodized aluminum makes it a popular choice for consumer electronics like smartphones, laptops, tablets, and audio equipment. Anodized finishes provide both aesthetics and protection against daily wear and tear.

- Sporting Goods: Anodized aluminum is used in sporting goods such as bicycle frames, golf clubs, and outdoor equipment. It combines lightweight design with durability, making it an ideal choice for high-performance gear.

- Art and Design: Anodized aluminum’s ability to take on a wide range of colors and textures has made it a preferred medium for artists and designers. It allows for creative expression in various forms, from sculptures and jewelry to architectural installations.

- Medical Devices: Anodized aluminum is utilized in medical instruments and devices due to its biocompatibility, corrosion resistance, and ease of sterilization. It is often used for surgical instruments and equipment.

- Industrial Applications: Anodized aluminum is employed in industrial equipment and machinery to enhance corrosion resistance, durability, and appearance. It is used for components subjected to harsh environments and chemical exposure.

- Marine Industry: The corrosion-resistant properties of anodized aluminum make it suitable for marine applications. Boat components such as masts, handrails, and fixtures often benefit from anodizing to withstand saltwater exposure.

- Military and Defense: Anodized aluminum is used in military and defense applications due to its durability and resistance to wear, corrosion, and harsh environmental conditions. It can be found in various equipment and vehicles.

- Electronics Enclosures: Anodized aluminum is commonly used for enclosures of electrical and electronic devices. It provides electromagnetic interference (EMI) shielding and protection against environmental factors.

- Food and Beverage Industry: Anodized aluminum is used for food processing equipment, storage tanks, and packaging machinery due to its corrosion resistance and ease of cleaning.

These applications highlight the versatility and importance of anodizing in modern manufacturing and design. Whether it’s enhancing the performance of critical aerospace components or adding an attractive finish to consumer products, anodizing plays a crucial role in numerous industries.

Conclusion

In conclusion, as we’ve delved into the fascinating world of anodizing, it becomes abundantly clear that this surface treatment process is a true game-changer. From enhancing the durability and aesthetics of aluminum to extending its applications to other materials, anodizing has left an indelible mark across a multitude of industries.

In an age where precision and quality are paramount, industries such as aerospace and automotive rely on the robust properties of anodized aluminum to ensure their components withstand the rigors of the skies and roads. Meanwhile, architects and designers turn to anodizing to add both functionality and visual appeal to their creations, creating structures that endure while captivating the eye.

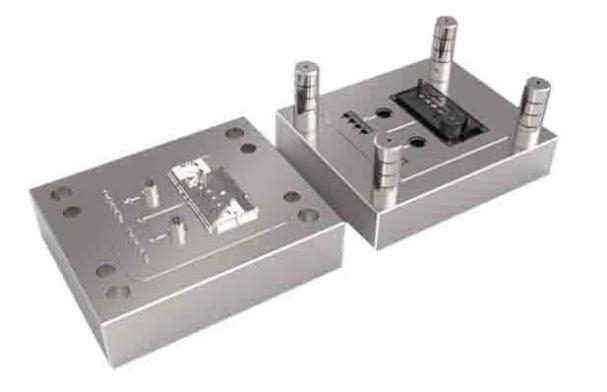

Moreover, as we embrace the digital age, it’s important to note that advancements in technology have made it easier than ever to access anodizing services. JTR, a China CNC machining factory, specializing in CNC machining, exemplifies this accessibility. These facilities offer state-of-the-art anodizing solutions, ensuring that industries worldwide can harness the benefits of this transformative process.

In this ever-evolving landscape, anodizing stands as a testament to the seamless fusion of art and science, where aesthetics and durability walk hand in hand. It remains a critical tool in the arsenal of modern manufacturing, promising a future filled with innovation, resilience, and endless possibilities.