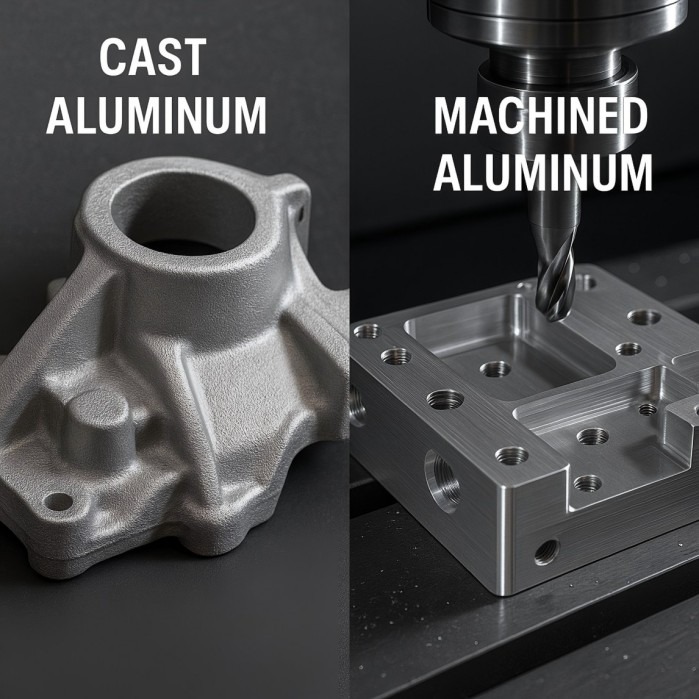

When you’re developing an aluminum component, choosing between cast aluminum and machined aluminum is a critical decision that impacts performance, cost, and lead time. The best material for tasks requiring accuracy and a high tolerance for delicate pieces and tight tolerances is machined aluminum. Larger, simpler pieces and applications where strength and endurance are crucial criteria are better suited for cast aluminum. The decision between machined aluminum and cast aluminum primarily depends on the requirements of your project.

As an experienced cast and CNC aluminum manufacturer, we at JTR understand the nuances of both processes and here break down 5 key considerations and provide 4 practical recommendations tailored to different production needs.

5 Considerations When Choosing Between Cast and Machined Aluminum

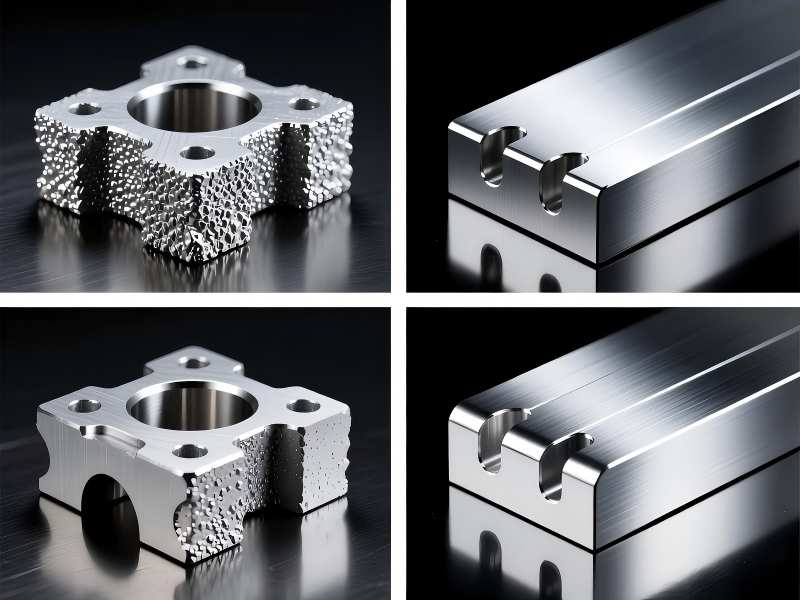

Consideration 1: Understanding the Specific Manufacturing Process

The fundamental difference lies in how the part is formed. Cast aluminum involves pouring molten aluminum into a mold, which then solidifies into the desired shape. This process includes various methods like die casting, sand casting, investment casting, and permanent mold casting, each with its own advantages regarding surface finish, dimensional accuracy, and tooling costs. For example, die casting is known for high volumes and excellent surface finishes, while sand casting offers flexibility for larger or more complex parts with lower tooling investment.

Conversely, machined aluminum (often referred to as CNC aluminum) starts with a solid block or billet of aluminum. Material is then progressively removed using computer numerical control (CNC) machines. This subtractive process allows for extremely precise shaping and intricate details. The choice of CNC machining centers, turning centers, or multi-axis machines depends on the part’s geometry and complexity. Understanding these foundational processes is the first step in aligning with your project’s needs.

| Feature | Cast Aluminum | CNC Machined Aluminum |

| Manufacturing Process | Mold pouring and solidification | Subtractive machining from solid billet |

| Suitable Production | High-volume | Low to medium volume |

| Design Flexibility | High (for complex shapes) | Moderate (limited by tool reach and setup) |

Consideration 2: Evaluating Key Performance Requirements

The functional demands of your component should guide material and process selection. For example:

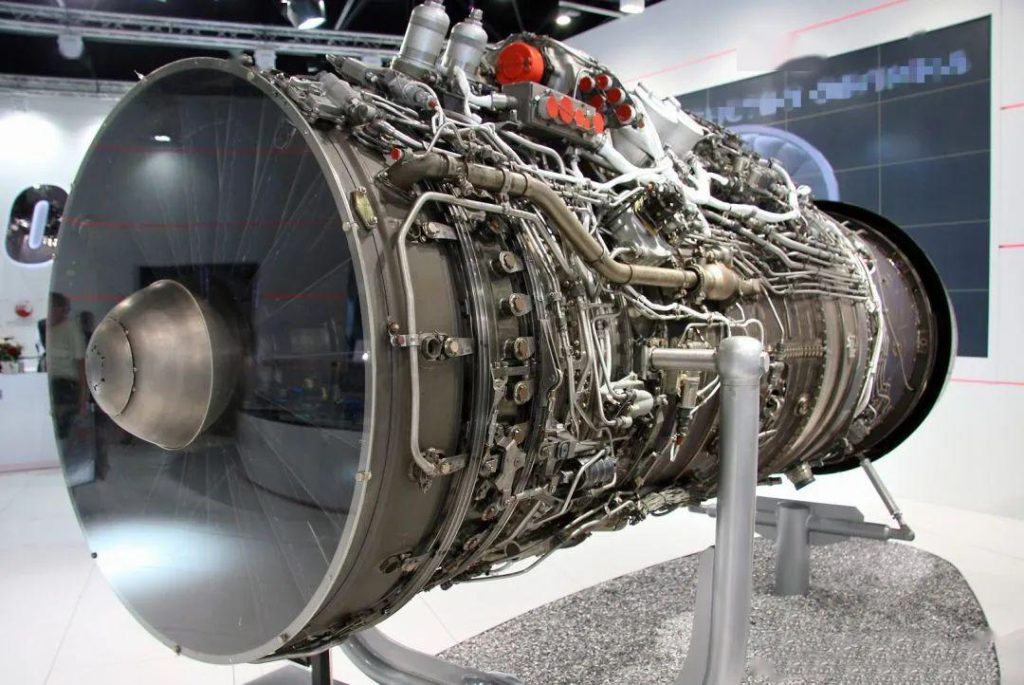

For high-strength applications, machined aluminum often provides superior mechanical properties. When a solid billet is machined, its grain structure remains intact and oriented, leading to higher tensile strength, yield strength, and fatigue resistance. For instance, 7075 aluminum alloy (a common aerospace alloy) is frequently machined due to its exceptional strength-to-weight ratio.

For applications requiring specific wear resistance or good thermal conductivity, certain cast aluminum alloys excel. For example, A380 (a popular die-casting alloy) offers excellent castability and good mechanical properties for general-purpose applications. For wear-intensive parts like cylinder liners, hypereutectic silicon alloys like B390 (a cast alloy) are specifically designed for their high silicon content, providing superior wear resistance that would be difficult and expensive to achieve through machining a wrought alloy.

Corrosion resistance can vary. While many aluminum alloys offer good natural corrosion resistance, the microstructure resulting from casting versus machining can influence performance in specific environments. 5xx.x series cast alloys (aluminum-magnesium) are known for excellent corrosion resistance, especially in marine environments, where they might be preferred over some machined alloys for certain applications.

Ultimately, balancing required strength, hardness, ductility, thermal performance, and corrosion resistance against material properties achievable through casting or machining is key.

The following are some common alloys and their properties.

Common CNC Machined Aluminum Alloys

| Alloy | Key Properties | Drawbacks |

| 6061 | Most widely used Excellent mechanical properties High weldability Good corrosion resistance | None significant; highly versatile |

| 7075 | Very high strength- Excellent fatigue resistance | Expensive Poor weldability |

| 2024 | High tensile strength Common in aerospace Good wear resistance | Poor corrosion resistance Limited weldability |

| 5052 / 6063 / 2014 | Suitable for CNC machining Varying corrosion resistance and strength levels | Alloy-specific limitations |

Common Cast Aluminum Alloys

| Alloy | Key Properties | Drawbacks |

| A380 | Lightweight Good performance at high temperatures High durability | None significant; casting-friendly |

| A383 | Corrosion resistant Good heat conductivity | Slightly lower strength than A380 |

| A360 | Excellent ductility Superior corrosion resistance | More difficult to cast |

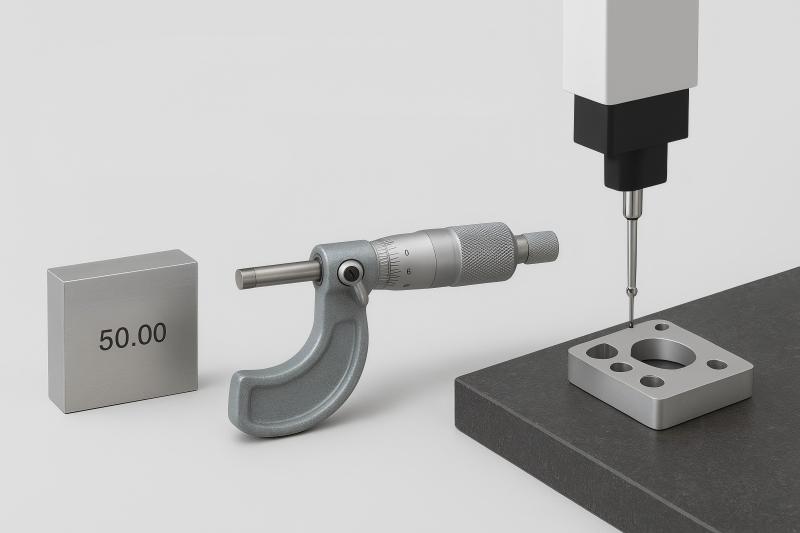

Consideration 3: Machining Precision and Complexity

This is where the distinct advantages of each method become particularly apparent.

| Feature | Cast Aluminum | Machined Aluminum (CNC) |

| Dimensional Accuracy | Good to moderate (typically ±0.1% to ±0.5%) | Excellent (as low as ±0.005% or better) |

| Surface Finish | Fair to good (depends on casting method: sand < permanent mold < die casting) | Excellent (can achieve very smooth finishes, e.g., Ra 0.8 μm) |

| Geometric Complexity | Very high, especially internal features and organic shapes | High, especially for intricate external details and tight tolerances |

| Internal Features | Excellent for complex internal passages (e.g., cooling channels) using cores | More challenging and costly for complex internal geometries that require multiple setups or specialized tools |

| Wall Thickness | Can achieve thin walls, especially with die casting (e.g., 1.5mm) | Can achieve very thin walls, limited by machining stability |

For parts demanding extremely tight tolerances, fine surface finishes, or sharp, precise edges, CNC aluminum is typically the superior choice. Aerospace components, medical devices, and precision instruments often rely on machining for their stringent accuracy requirements. For instance, a complex valve body requiring precise internal fluid passages might leverage the ability of casting to create those features efficiently, even if external surfaces need some post-machining for critical mating areas.

Consideration 4: Production Cost and Efficiency

Cost is often a major driver in process selection, and it’s heavily influenced by production volume and lead time.

Tooling Costs: Cast aluminum typically involves significant upfront tooling costs for molds (especially for die casting, which can range from $50,000 to $250,000+ for complex dies). However, once the mold is made, the per-part cost for large volumes is very low. Machined aluminum, on the other hand, has minimal or no tooling costs for individual parts, as it uses standard cutting tools.

Unit Cost: For high-volume production (thousands to millions of units), casting almost always offers a lower unit cost due to rapid cycle times and reduced material waste per part. For example, a die-cast automotive bracket might cost $2-5 per unit in high volume, while a machined equivalent could be $20-50+.

Lead Time: Casting has a longer initial lead time due to mold design and fabrication (weeks to months). Once tooling is ready, production is fast. Machining has a shorter initial lead time as programming can begin quickly, and parts can be produced on demand. For prototypes or low volumes, machining is significantly faster to get parts in hand.

Production Volume:

- Low Volume (1-100 units): Machining is usually more cost-effective.

- Medium Volume (100-5,000 units): Either process might be viable; detailed cost analysis is needed.

- High Volume (5,000+ units): Casting (especially die casting) becomes the most economical choice.

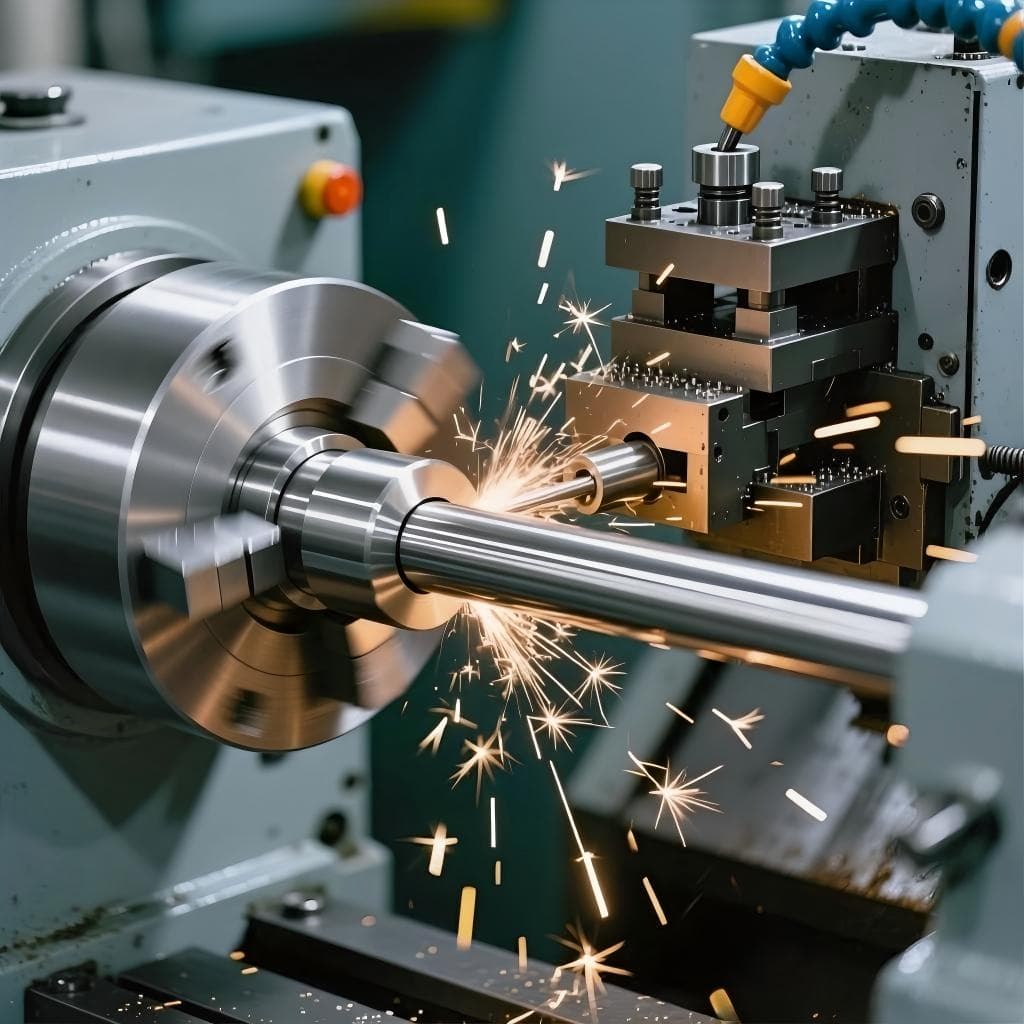

Consideration 5: Material Utilization and Waste Management

The amount of material consumed and waste generated impacts both cost and environmental footprint.

Cast aluminum is generally more material-efficient for complex shapes. The molten metal fills the mold cavity directly, and excess material (runners, risers, gates) is typically melted down and reused. While there’s initial material waste from sprues and risers, the net utilization for the finished part can be very high, especially for intricate designs that would generate a lot of chips if machined from a solid block.

Machined aluminum is a subtractive process, meaning a significant amount of material is converted into chips. For a part with a complex internal geometry that requires extensive milling from a solid billet, the material utilization can be as low as 10-20% (meaning 80-90% becomes chips). While these chips are recyclable, the energy and cost associated with machining and recycling can be substantial. For simpler geometries, material utilization can be much higher.

| Waste & Efficiency | Cast Aluminum | CNC Machined Aluminum |

| Material Waste | Low | High |

| Sustainability Impact | More efficient | Can be improved with recycling |

4 Application-Based Recommendations

Based on your project’s specific requirements, here are our recommendations:

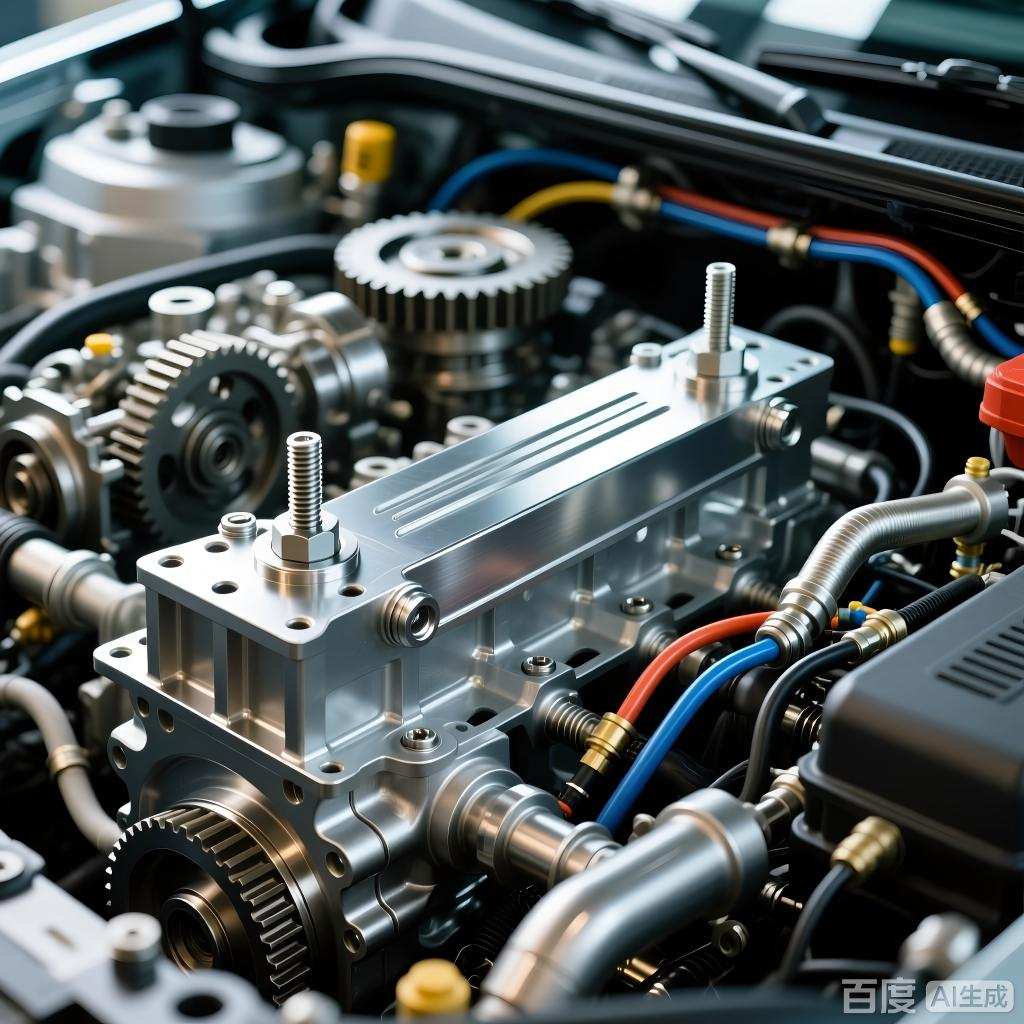

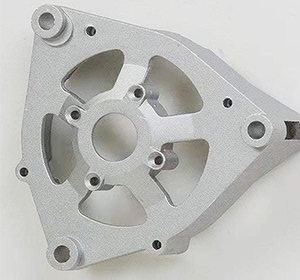

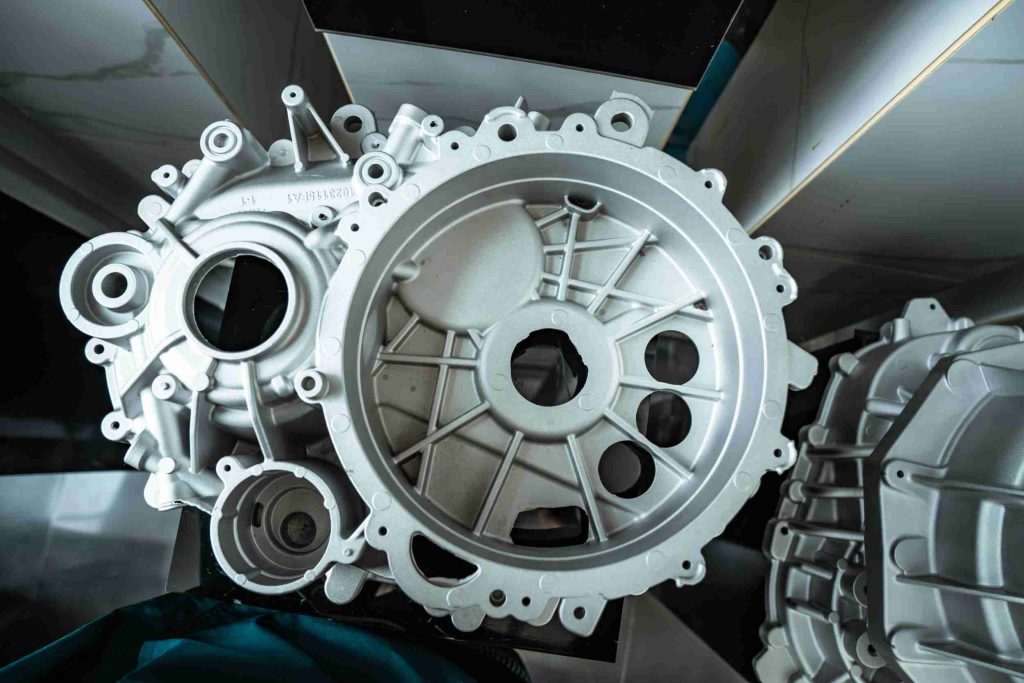

1. Extremely Complex Shapes + Internal Features + High Volume

(e.g., Automotive Engine Blocks, Complex Housings, Manifolds)

For parts like these, where intricate internal passages (e.g., cooling channels in an engine block, or complex air/fluid flow paths in a manifold) are essential and production quantities are very high, cast aluminum, specifically high-pressure die casting or permanent mold casting, is highly recommended.

Why: Casting is uniquely suited to form complex internal geometries that would be prohibitively expensive or impossible to machine from a solid block. The upfront investment in tooling is justified by the extremely low per-part cost, rapid cycle times, and excellent material utilization over large production runs. Alloys like A380 or 319 (for die casting) or A356 (for permanent mold) offer the necessary fluidity and mechanical properties for these applications.

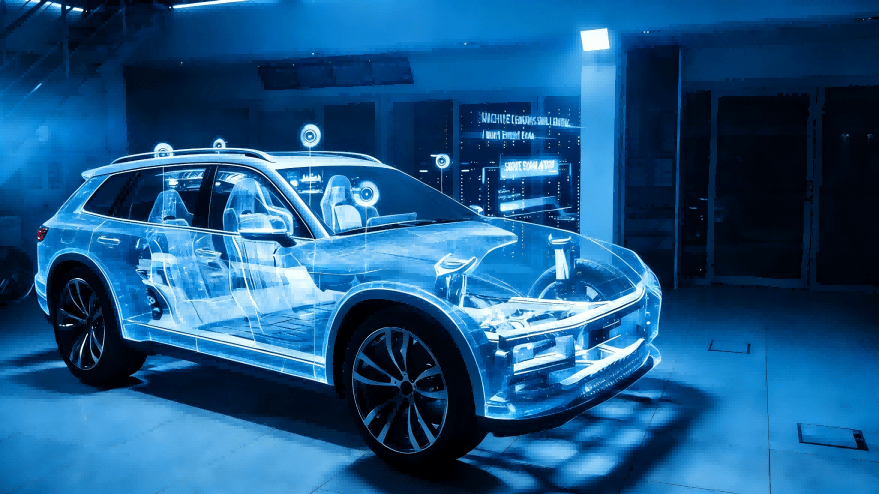

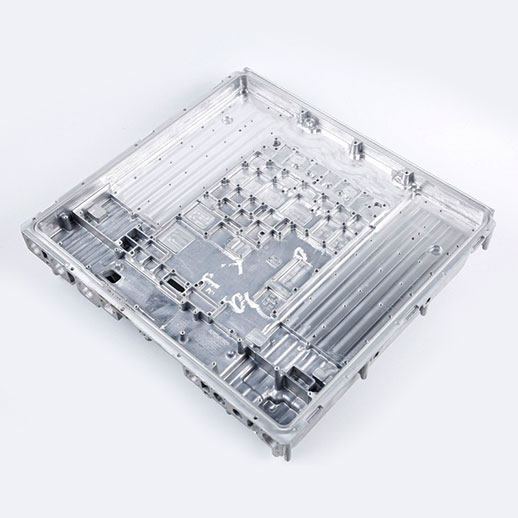

2. High Precision + High Strength + Excellent Surface Finish + Small to Medium Volume

(e.g., Aerospace Brackets, Optical Instrument Components, Precision Fixtures, Robotic Joints)

When your priority is extreme dimensional accuracy, superior mechanical properties, and a flawless surface finish, and your volumes are not in the tens of thousands, machined aluminum (CNC aluminum) is the optimal choice.

Why: CNC machining allows for micron-level tolerances, exceptional surface finishes (often eliminating the need for further finishing steps), and the ability to work with high-strength, heat-treatable wrought alloys like 6061 or 7075. While the per-part cost might be higher than casting for large volumes, the absence of expensive tooling, faster initial lead times, and unparalleled precision make it ideal for critical components in industries like aerospace or robotics where failure is not an option and performance dictates the material and process. For example, a robotic arm joint might demand the precision of CNC aluminum to ensure smooth, repeatable motion.

3. Moderate Complexity + Moderate Volume

For parts with a good balance of features, acceptable surface finish, and mid-range production needs, you have more flexibility.

Recommendation: Consider permanent mold casting or a combination of sand casting with post-machining. If the geometry is not overly complex and the quantity is substantial enough to amortize mold costs, permanent mold casting can offer better mechanical properties and surface finish than sand casting, at a lower tooling cost than die casting. If the part has some features requiring higher precision, casting the near-net shape and then performing post-CNC machining on critical surfaces is a cost-effective hybrid approach. This allows you to leverage the cost benefits of casting for the bulk of the part while achieving tight tolerances where needed.

4. Prototype/Trial Phase (Regardless of Final Choice)

For initial prototypes and design validation, CNC aluminum is almost always the best choice.

Why: Prototyping needs speed and flexibility. Creating a mold for casting is time-consuming and expensive. With CNC machining, you can rapidly iterate on designs, make modifications quickly, and test functional prototypes without the significant upfront investment in tooling. This allows for quick design cycles, saving time and money in the long run, even if the final production method will be casting. Once the design is validated through machined prototypes, then you can commit to costly casting tooling.

When to Choose What

Choose Casting when:

- Your parts have high complexity with intricate internal features.

- You require high-volume production to minimize per-part cost.

- You can tolerate a slightly less precise surface finish and dimensional accuracy (though die casting can be very good).

- Your budget allows for higher upfront tooling costs.

Choose Machining when:

- Your parts demand extreme precision, tight tolerances, and superior surface finishes.

- You need maximum strength and specific material properties from wrought alloys.

- Your production volume is low to medium, or you’re in the prototyping phase.

- You need fast lead times for initial parts or design iterations.

Consider a Hybrid Approach when:

The part has a complex overall shape but requires critical high-precision features. You can cast the near-net shape and then machine the crucial areas. This can optimize both cost and performance.

The Importance of Choosing the Right Manufacturer

Selecting a manufacturer with expertise in both cast aluminum and machined aluminum is crucial. A specialist like JTR brings a comprehensive understanding of both processes, allowing us to provide unbiased, expert advice tailored to your project.

At JTR, we pride ourselves on being a leading aluminum casting manufacturer and CNC aluminum manufacturer. Our advantages in these areas include:

- Extensive Casting Capabilities: We offer a range of aluminum casting services, including die casting, sand casting, and permanent mold casting, supported by advanced equipment and experienced metallurgists to ensure optimal material properties and structural integrity.

- State-of-the-Art CNC Machining: Our facility is equipped with precision CNC machining centers capable of holding tight tolerances and producing complex geometries with excellent surface finishes from various aluminum alloys.

- Integrated Solutions: We can manage projects that involve both casting and post-machining, offering a seamless production flow and ensuring quality control from start to finish.

- Material Expertise: Our deep knowledge of aluminum alloys, both cast and wrought, allows us to recommend the ideal material for your specific performance requirements.

- Value Engineering: We work with you from the design phase to identify potential cost savings and efficiency improvements, ensuring you get the most out of your manufacturing budget.

JTR can provide both CNC machining services and die-casting services. We can provide excellent cast aluminum parts, as well as machined aluminum parts. If you want to process different types of aluminum products, please contact us.

By partnering with JTR, you gain access to a partner who can expertly navigate the complexities of cast aluminum vs. machined aluminum, ensuring your final component meets all your performance, cost, and delivery objectives.