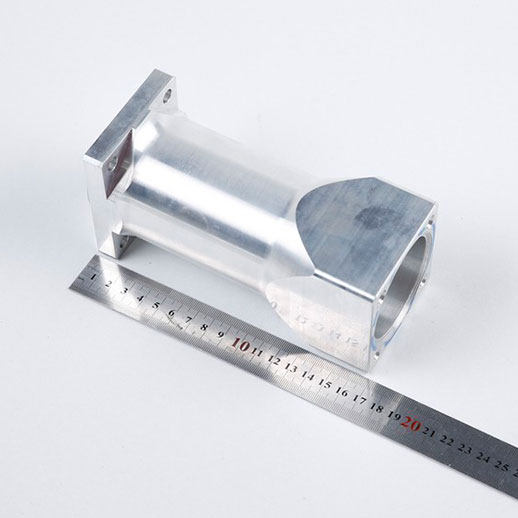

Precision CNC Turning Aluminum Parts

- Identification of Product: P004

- Size: 164*320(mm)

- Material: Aluminum Alloy6061-T6

- Treatment: None

- CNC machining process: raw material→heat treatment→CNC turning→CNC milling

- Weight: 3.48KG

- Features: No oxidization on the appearance, no scratch allowed on the surface, and the inner cavity is deep.

Description

Raw material – Al6061-T6 aluminum alloy rod

The main alloying elements of AI6061 T6 are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and good oxidation effect.

AI6061 T6 is the state of artificial aging after solution heat treatment. It is suitable for products that are not subjected to cold working after solution heat treatment (straightening and leveling can be carried out, but the limit of mechanical properties is not affected).

CNC Machining process – CNC 3-axis machining → CNC 4-axis machining

The 3-axis machining center has the characteristics of high cost performance, simple structure, and convenient maintenance. This kind of machining center is cheaper than the 4-axis and five-axis vertical machining centers, and the 3-axis machining center does not have 4-axis and 5-axis vertical machining centers. The auxiliary structure of the machining center, so it is equivalent to easy maintenance.

However, the processing range of the 3-axis machining center is limited, and only one machining surface can be processed by clamping at a time. However, the 3-axis machining center can be configured with the fourth axis and the fifth axis, which can expand the scope of its machining center. The three-axis vertical machining center has increased After the fourth axis or the fifth axis, the workpiece can be clamped at one time to complete the processing of multiple surfaces.

Advantages of CNC machining:

① The number of tooling is greatly reduced, and complex tooling is not required to process parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for the development and modification of new products.

②Stable processing quality, high processing precision and high repeatability, which can meet the requirements of aircraft processing.

③In the case of multi-variety and small batch production, the production efficiency is high, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

④ It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processed parts.