Cast Aluminum vs Machined Aluminum: Which Is Right for Your Application?

Due to their excellent strength-to-weight ratio, resistance to corrosion, and…

Due to their excellent strength-to-weight ratio, resistance to corrosion, and…

In the hyper-competitive world of consumer electronics and industrial devices,…

In today’s pursuit of carbon neutrality and electrification, every gram…

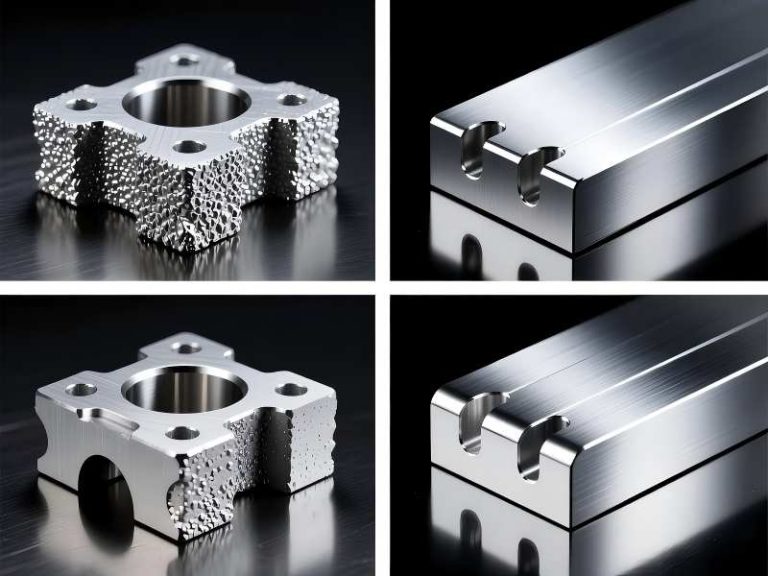

The choice of process determines a part’s performance, cost, and…

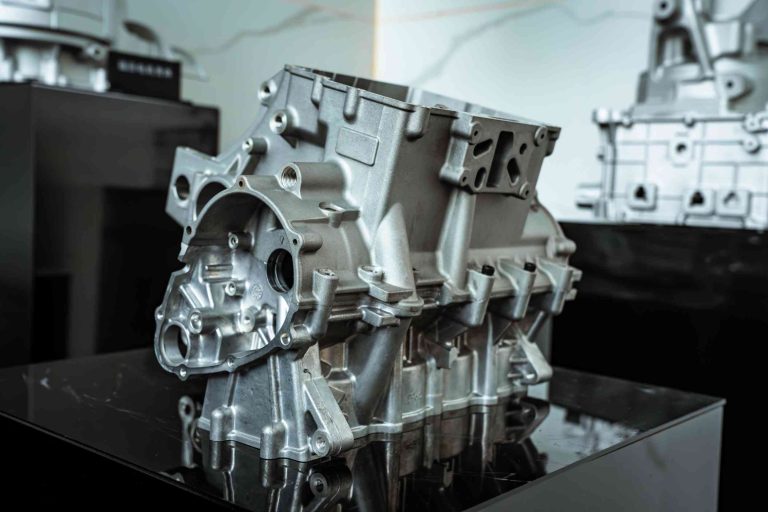

What Is the Best Casting Method for Automotive Parts?

How Do I Choose Between Sand Casting and Investment Casting?

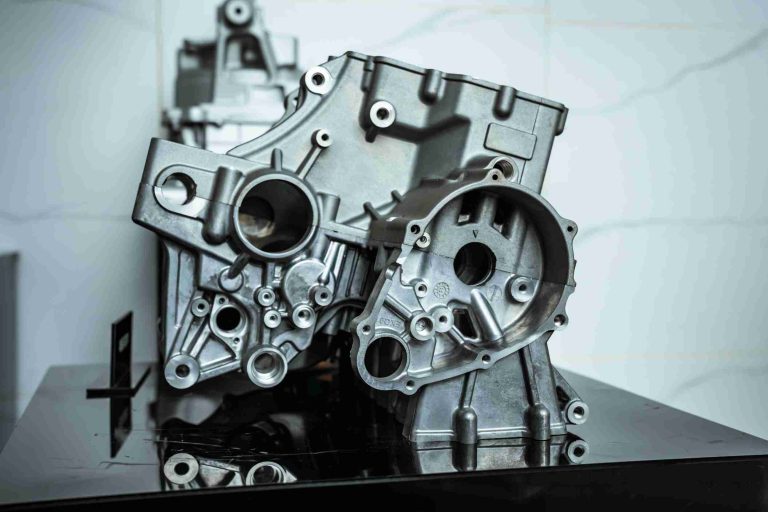

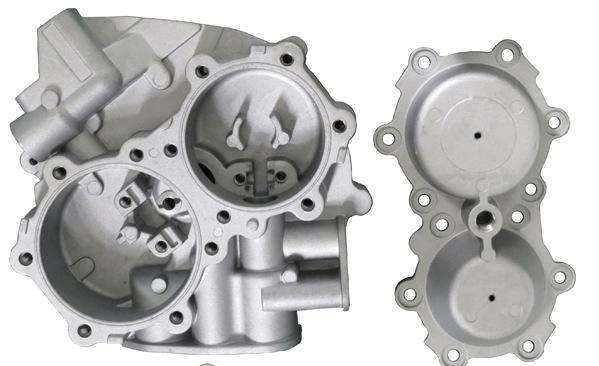

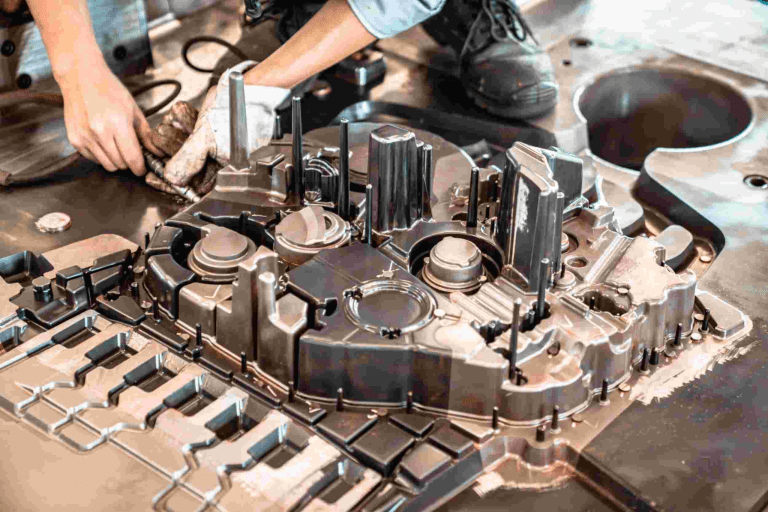

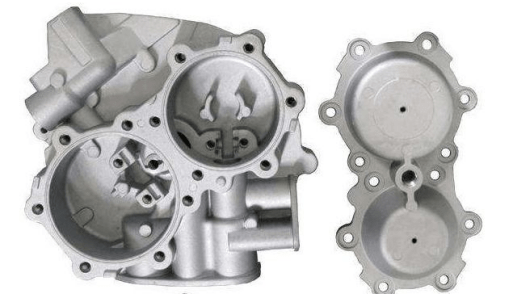

Casting is a fundamental manufacturing process used to create complex metal parts by pouring molten metal into a mold. Sand casting and die casting are two of the most common methods, each with distinct advantages, applications, and cost implications.

Casting is a foundational process in manufacturing, enabling the creation…

Die casting is a manufacturing process where molten metal is injected…

The automotive manufacturing industry has been seeking ways to improve efficiency,…

Casting processes hold a pivotal role in manufacturing, serving as the…

In modern industrial production, high-pressure die-casting technology is widely used…

Request A Quote