5 Key Features of High-Quality Die Casting Molds

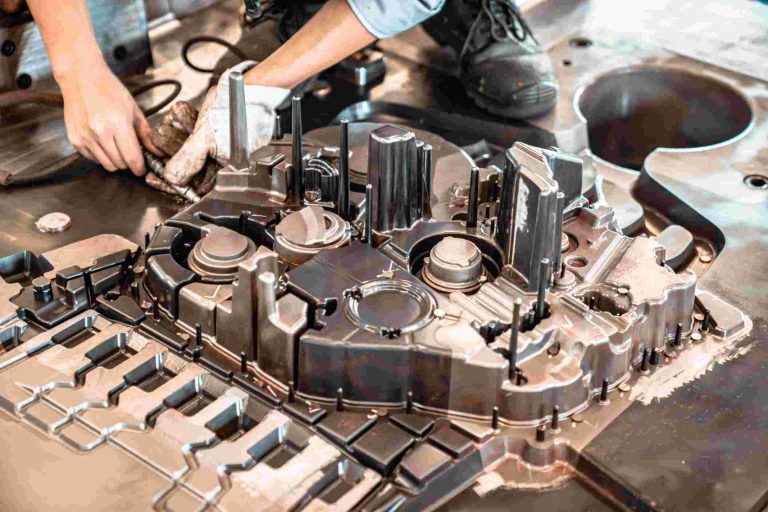

Die casting molds are at the heart of the die casting…

Die casting molds are at the heart of the die casting…

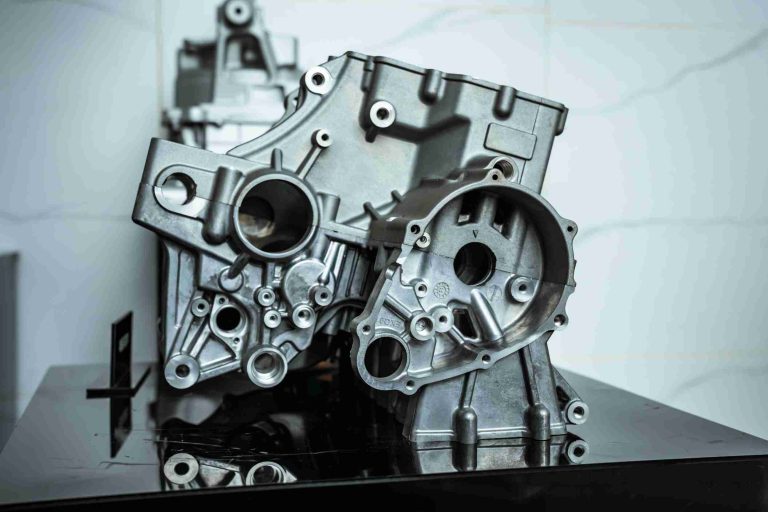

Aluminum casting is a widely used method in manufacturing to create…

The automotive industry has long relied on aluminum for its…

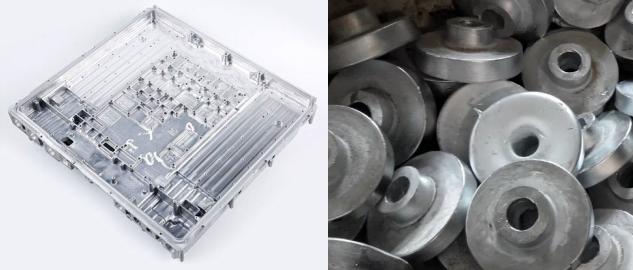

Die casting is a widely used metalworking process for producing high-volume,…

In the realm of manufacturing, the choice of casting method…

Zamak die casting stands as a cornerstone in the realm…

Imagine molten metal transformed into intricate, lightweight, and incredibly strong…

In the ever-evolving landscape of manufacturing, precision engineering plays a…

In the world of manufacturing, the choice of the right…

Aluminum die casting is a versatile manufacturing process that offers numerous…

Casting is an early metal thermal processing process, which has…

Generally speaking, the factors that affect the service life of…

Request A Quote