Not all 3D printing technologies serve the same purpose. If you’re unsure whether to choose SLA or SLS for your project, this guide breaks down the practical, technical, and material differences—helping you select the right solution based on real needs, not marketing jargon.

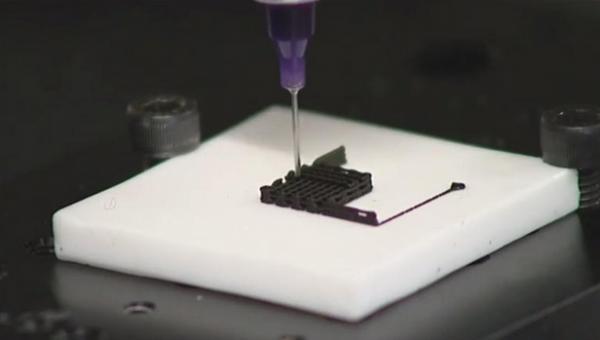

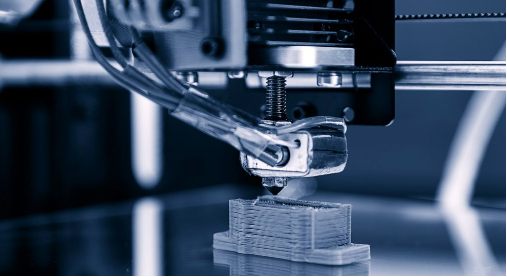

What Is SLA 3D Printing?

SLA 3D printing(Stereolithography) uses a focused UV laser to selectively cure liquid resin layer by layer. This creates highly detailed, smooth parts with excellent resolution, making SLA ideal for prototypes where appearance and fine details matter.

Advantages of SLA

✔ Ultra-fine resolution for small or complex parts

✔ Smooth surface finish, minimal post-processing

✔ Suitable for visual prototypes, presentation models, dental, jewelry

Considerations

- Requires support structures

- Limited mechanical strength for functional parts

- Resin properties vary (standard, high-temp, flexible options available)

Use SLA when:You need high-detail prototypes, aesthetic models, or intricate small components not exposed to heavy loads.

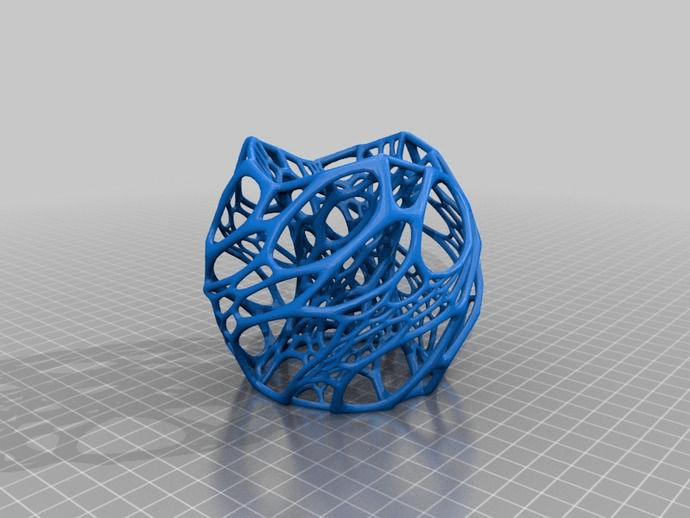

What Is SLS 3D Printing

SLS 3D printing(Selective Laser Sintering) fuses powdered materials like nylon or composites using a high-powered infrared laser. The surrounding unsintered powder naturally supports the part during printing, allowing complex geometries without external supports.

Advantages of SLS

✔ Excellent mechanical strength, durable prototypes

✔ Design freedom—internal channels, overhangs, complex shapes

✔ Efficient material use—unsintered powder is recyclable

✔ No need for support removal, saving post-processing time

Considerations

- Surface is textured, may require finishing for aesthetics

- Higher machine and material cost compared to basic SLA

- More suited for functional parts than visual prototypes

Use SLS when:You need load-bearing prototypes, functional testing parts, or components with complex internal structures.

What is the Difference Between SLA 3D Printing and SLS 3D Printing?

SLA vs SLS 3D Printing–Technical Metrics Comparison

| Category | SLA (Stereolithography) | SLS (Selective Laser Sintering) |

| Material Type | Liquid photopolymer resin | Nylon powders, composite polymer blends, metal-ceramic mix |

| Energy Source | Ultraviolet (UV) laser | Infrared laser for powder sintering |

| Layer Thickness | 25 – 100 microns (high precision) | 100 – 150 microns (functional tolerances) |

| Mechanical Strength | Moderate, brittle under heavy load | High strength, durable for functional parts |

| Heat Resistance | Depends on resin grade | Excellent with specific materials (e.g., Nylon 12) |

| Material Reusability | Limited, resin often single-use | High, unsintered powder is recyclable |

| Support Structures | Required, removed post-print | Not required, powder provides natural support |

SLA vs SLS 3D Printing–Application Scenarios

| Application Requirement | Recommended Technology | Reason |

| High-detail, small, aesthetic parts | SLA | Fine resolution, smooth surface, ideal for visual prototypes |

| Functional prototypes, load-bearing parts | SLS | Robust mechanical strength, complex internal geometries |

| Complex internal structures | SLS | No support needed, allows intricate enclosed features |

| Medical & dental models | SLA (biocompatible resin) | Smooth finish, fine detail, available certified materials |

| Short-run production parts | SLS | Strong, functional-grade, reusable material reduces waste |

SLA vs SLS 3D Printing-Design Freedom & Structural Complexity

| Factor | SLA | SLS |

| Support Requirement | Mandatory, affects design freedom | No external supports, powder supports structure |

| Overhangs & Internal Cavities | Possible but requires accessible support removal | Fully enclosed internal features achievable |

| Geometry Complexity | Limited by support design | High, ideal for complex or lattice structures |

| Part Consolidation Potential | Moderate | High, reduces assembly requirements |

SLA vs SLS 3D Printing–Resolution & Surface Finish

| Aspect | SLA | SLS |

| Surface Quality | Smooth, polished, minimal post-processing | Textured, matte, optional smoothing for aesthetics |

| Feature Resolution | Extremely fine, sharp edges possible | Functional tolerance, less sharp details |

| Visual Prototype Suitability | Excellent | Adequate but rougher surface may require finishing |

| Post-processing Requirements | Support removal, UV curing recommended | Basic cleaning, optional finishing for surface smoothness |

Fundamental Principle: How SLA and SLS Build Parts Differently

| Technology | SLA (Stereolithography) | SLS (Selective Laser Sintering) |

| Process Mechanism | UV laser selectively cures liquid resin, layer by layer | Infrared laser sinters powdered material, fusing solid layers |

| Material State During Printing | Liquid resin vat | Powder bed |

| Layer Solidification | Point-to-line-to-surface curing | Powder layer fusion via thermal energy |

| Structural Support During Build | Supports printed alongside part | Surrounding unsintered powder supports part naturally |

SLA 3D Printing and SLS 3D Printing – How to Choose

- ✔ Product design teams needing high-detail concept models → SLA

- ✔ Medical & dental applications requiring biocompatible, smooth surfaces → SLA with certified resin

- ✔ Functional mechanical prototypes for automotive, aerospace, consumer goods → SLS

- ✔ Complex internal structures impossible with supports → SLS

- ✔ Short-run end-use parts for industrial use → SLS

Conclusion

There’s no universal answer—select the technology that aligns with:

✅ Your part’s functional requirements

✅ Expected mechanical performance

✅ Visual appearance needs

✅ Budget and production scale

SLA = High-detail prototypes, visual models

SLS = Tough, functional parts, complex designs

Need tailored advice? We offer both SLA and SLS 3D printing with expert consultation to match your technical and commercial requirements.

Upload your design files today for a fast, accurate assessment.