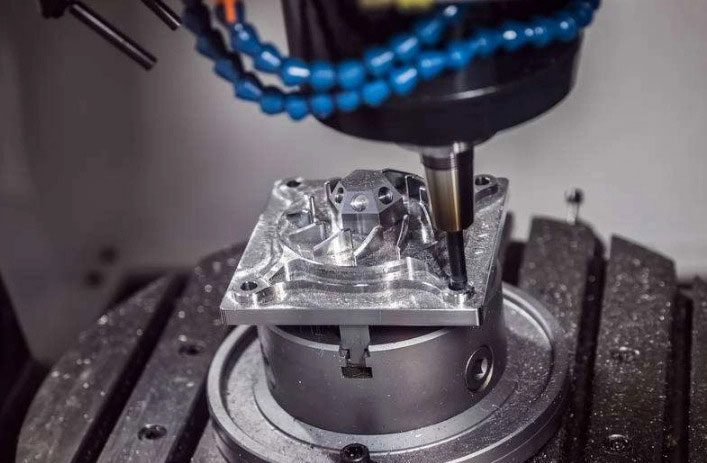

CNC machining occupies a very high position in CNC equipment. Many parts processing companies use CNC machining centers. So what types of parts can be produced with CNC machining? This article will analyze the advantages of CNC machining to answer the types of CNC machining parts for you.

Why Choose CNC Machining? 3 Advantages

- CNC can automatically process

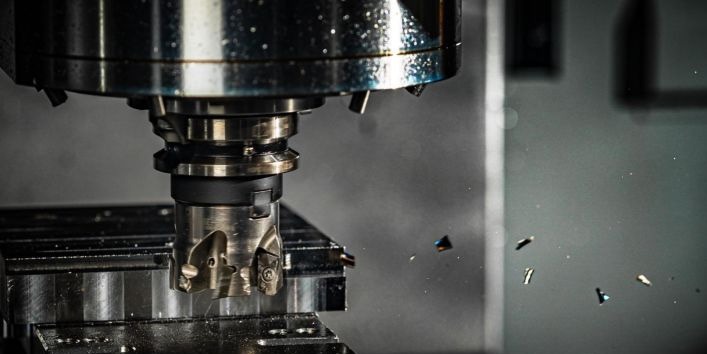

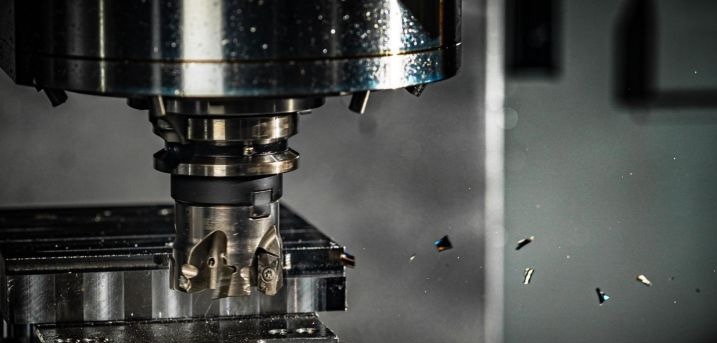

CNC machining usually refers to precision machining controlled by computer numerical control. Therefore, it can be controlled by the program instructions of the CNC machine tool, and the entire processing process will be automatically carried out according to the program instructions. Another benefit of the high degree of automation of machine tools is that the labor intensity of workers is greatly reduced.

Today, many CNC machines can run unattended throughout their machining cycles, freeing up operators for other tasks. This has several side benefits for CNC users, including reduced operator fatigue, fewer errors due to human error, and consistent and predictable machining times for each workpiece.

- High CNC machining accuracy

The second major advantage of CNC technology is the consistency and accuracy of the workpiece. The typical accuracy of today’s CNC machines is 2 to 4 thousandths of an inch or 0.05 to 0.10 mm, with repeatability approaching or better than 8 thousandths of an inch or 0.02 mm.

This means that once a program is validated, two, ten, or a thousand identical parts can easily be produced with the same precision and consistency. Mass production can be achieved, and product quality is easy to control.

- High flexibility in CNC machining

Since these machines are run by computer programs, running different workpieces is as simple as loading different programs. Programs can be changed quickly to produce parts to specification.

As we all know, CNC machining centers are suitable for complex machining parts, have many procedures, have high requirements, require various types of ordinary machine tools and various tool fixtures, and can only be processed after multiple clamping adjustments. Therefore, the types of products processed by CNC are mainly box parts, parts with complex curved surfaces, special-shaped parts, clad parts, and parts with special requirements.

Types of CNC Machining Parts

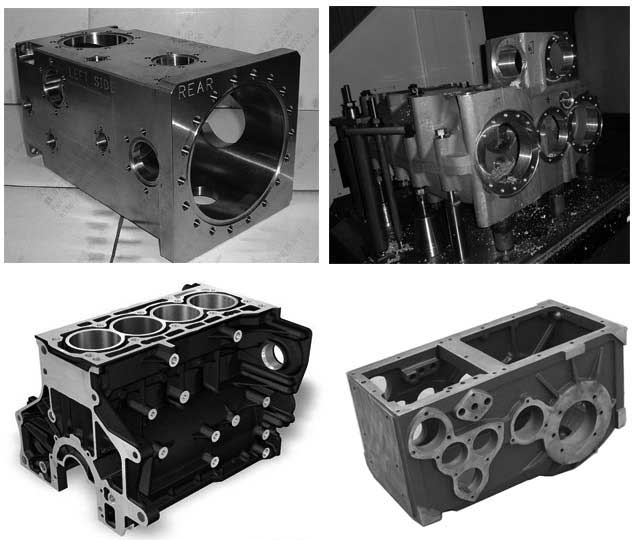

CNC Machining Box Parts

Box parts generally refer to parts with multiple holes, cavities inside, and a certain proportion of length, width, and height. Such parts are mostly used in machine tools, automobiles, aircraft manufacturing, and other industries.

Box-shaped parts generally require multi-station hole-making and plane processing, with high tolerance requirements, especially the geometric tolerance requirements are relatively strict, usually through milling, drilling, expanding, boring, reaming, countersinking, tapping, and other processes. more knives.

For the machining center for machining box parts, when there are many machining stations, the horizontal boring, and milling CNC machining center is generally selected when the worktable needs to be rotated several times to complete the parts.

CNC Machining Parts with Complex Surfaces

The complex curved surfaces of parts play a particularly important role in mechanical manufacturing, especially in the aerospace industry. It is difficult or even impossible to complete complex surfaces using ordinary machining methods.

The traditional method of machining parts with complex curved surfaces is precision casting, so it is conceivable that its precision is low. Complex surface parts include various impellers, wind guide wheels, spherical surfaces, various surface-forming dies, propellers and underwater vehicle propellers, and some other free-form surfaces.

CNC Machining Shaped Parts

Special-shaped parts are parts with irregular shapes, most of which require multi-station mixed processing of points, lines, and surfaces. The rigidity of special-shaped parts is generally poor, the clamping deformation is difficult to control, the machining accuracy is difficult to guarantee, and even some parts of some parts are difficult to complete with ordinary machine tools.

When processing with a machining center, reasonable technological measures should be taken, one or two clampings, and the characteristics of the machining center’s multi-station point, line, and surface mixing processing should be used to complete multiple or all processes.

CNC Machining Disc Parts, Sleeves, and Plates

End face with keyway, or radial hole, or distributed hole system, crankcase or shaft parts, such as flange bushing, keyway or square head shaft parts, etc., and multi-hole machined plate parts, such as various motor end faces have Vertical machining centers should be selected for disc parts with distributed holes and curved surfaces. In contrast, horizontal machining centers with radial holes should be selected.

New Product Trial Parts

The machining center has wide adaptability and high flexibility. When changing the processing object, you only need to compile and input a new program to realize processing.

Summary

As the main production method of parts, CNC machining is widely used in industry and parts manufacturing. CNC can produce most standard or non-standard parts by machining. Just like us at JTR CNC Machining Service, we produce tens of thousands of production parts for different companies and different manufacturers every year. As the mainstream part processing method, CNC machining has always been the best choice for equipment manufacturers.