In the realm of manufacturing, precision parts play a pivotal role in the assembly of machinery, electronics, aerospace, automotive, and a myriad of other industries. As demands for intricate designs, impeccable accuracy, and specialized functionalities surge, the customization of CNC precision parts has emerged as a cornerstone of modern manufacturing processes. From the automotive industry’s need for intricately designed engine components to the aerospace sector’s requirements for lightweight yet durable parts, customization has become the norm rather than the exception. Let’s delve into why customized machining is gaining traction, the methods employed, the advanced technologies driving the process, and the factors influencing CNC precision parts customization.

Why Customized Machining Become More Popular?

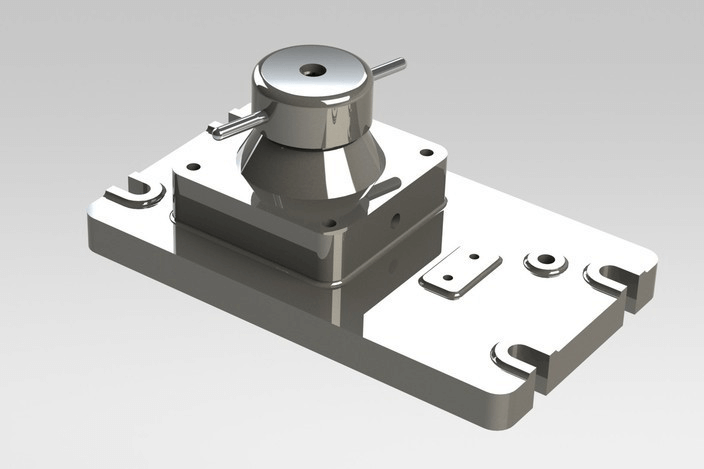

Customized machining offers unparalleled flexibility, allowing manufacturers to tailor parts to exact specifications and requirements. This flexibility is particularly crucial in industries where off-the-shelf components may not suffice due to unique design needs or performance criteria. By opting for customized machining, companies can achieve precise geometries, tolerances, and surface finishes, ensuring optimal performance and compatibility with the final product. Moreover, customized parts can enhance efficiency by minimizing the need for secondary operations or modifications, streamlining the manufacturing process, and reducing costs associated with rework or scrap.

What Are the Ways of Precision Parts Customization?

Precision parts customization encompasses various methodologies tailored to meet specific design and functional criteria:

- Computer-Aided Design (CAD): CAD software enables engineers to create intricate 3D models of parts, facilitating precise visualization and design optimization before the machining process begins.

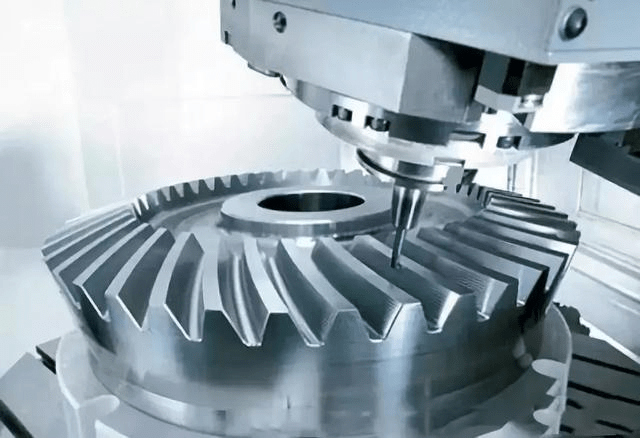

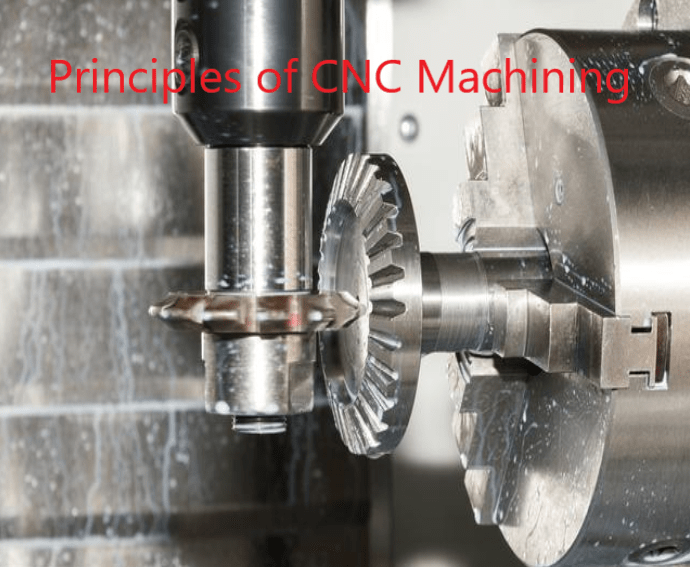

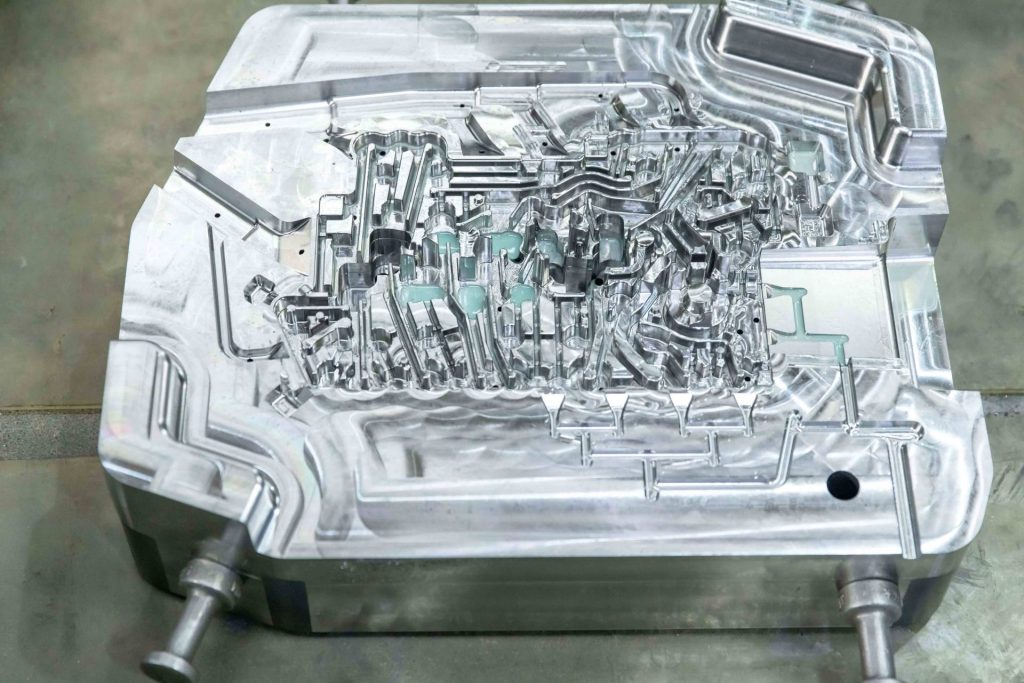

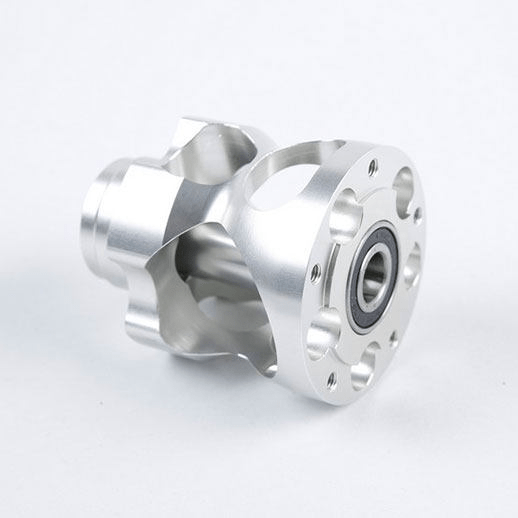

- Computer Numerical Control (CNC) Machining: CNC machining employs computer-controlled tools to precisely shape raw materials into finished parts according to CAD specifications. This process offers unparalleled accuracy and repeatability, making it ideal for producing complex geometries and tight tolerances.

- Additive Manufacturing (AM): Additive manufacturing techniques, such as 3D printing, enable the layer-by-layer deposition of materials to create intricate parts with minimal material waste. AM technologies complement traditional CNC machining by offering rapid prototyping capabilities and the ability to produce complex geometries that may be challenging to achieve using conventional methods.

- Post-Machining Treatments: Beyond the machining process itself, precision parts may undergo various post-processing treatments, including surface finishing, heat treatment, and coating applications, to enhance their durability, corrosion resistance, and aesthetic appeal.

Advanced Technologies in CNC Precision Machining Customization

The evolution of technology has revolutionized CNC precision machining, enabling manufacturers to push the boundaries of innovation and efficiency. Some of the advanced technologies driving customization include:

- Multi-Axis Machining: Multi-axis CNC machines can manipulate workpieces along multiple axes simultaneously, allowing for intricate geometries and complex contours to be machined with unprecedented precision and efficiency.

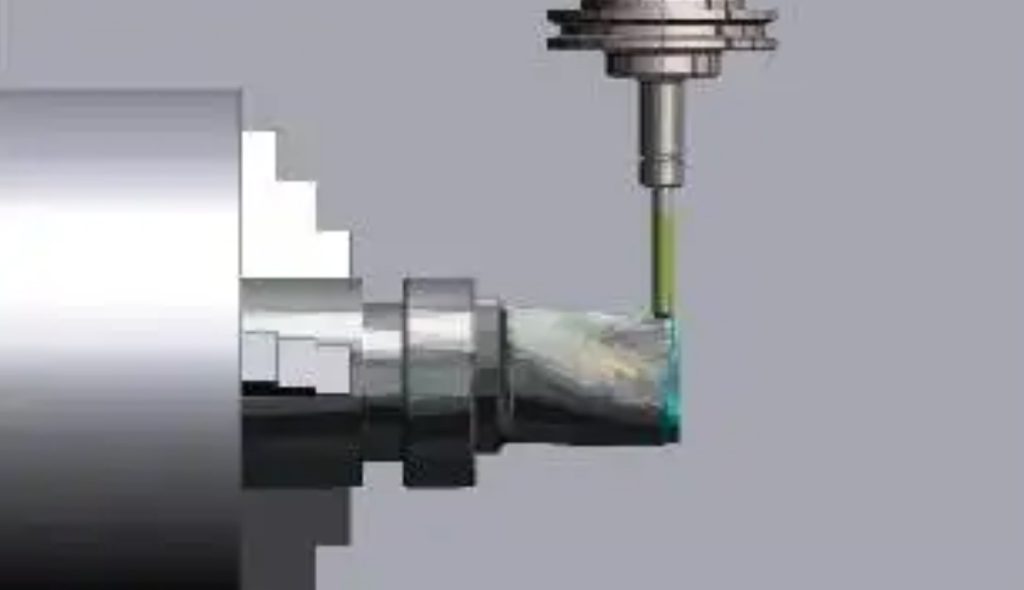

- High-Speed Machining (HSM): HSM techniques leverage high spindle speeds and feed rates to accelerate material removal rates while maintaining tight tolerances and surface finishes. This enables manufacturers to reduce cycle times and increase productivity without compromising quality.

- Advanced Tooling and Materials: The development of cutting-edge tooling materials, such as carbide and ceramic inserts, coupled with advancements in machining strategies, enables manufacturers to tackle challenging materials like titanium, Inconel, and composites with ease, expanding the possibilities for precision parts customization.

- Integrated Automation and Robotics: Automation and robotics are increasingly integrated into CNC machining workflows to streamline production processes, minimize human error, and enhance overall productivity. From automated tool changers to robotic part loading and unloading systems, these technologies enable manufacturers to optimize throughput and efficiency while reducing labor costs.

Factors Influencing Customized Machining CNC Precision Parts

Several factors influence the decision to opt for customized machining of CNC precision parts:

- Design Complexity and Innovation: Industries requiring intricate designs and innovative solutions often rely on customized machining to bring their concepts to fruition, enabling them to stay ahead of the curve in a competitive marketplace.

- Quality and Performance Requirements: Industries with stringent quality and performance standards, such as aerospace and medical device manufacturing, often turn to customized machining to ensure that their parts meet or exceed regulatory requirements and industry benchmarks.

- Cost Considerations: While customized machining offers unparalleled precision and flexibility, it may entail higher upfront costs compared to off-the-shelf components. However, the long-term benefits in terms of performance, efficiency, and reliability often outweigh the initial investment.

- Supply Chain Resilience: In an era marked by supply chain disruptions and geopolitical uncertainties, many companies are reassessing their reliance on overseas suppliers and exploring domestic or localized manufacturing solutions through customized machining.

In conclusion, the customized machining process of CNC precision parts represents a paradigm shift in modern manufacturing, offering unparalleled flexibility, precision, and efficiency across a myriad of industries. As technology continues to evolve and customer demands become increasingly sophisticated, the role of customization in shaping the future of manufacturing is poised to expand, driving innovation and unlocking new possibilities in the pursuit of excellence.