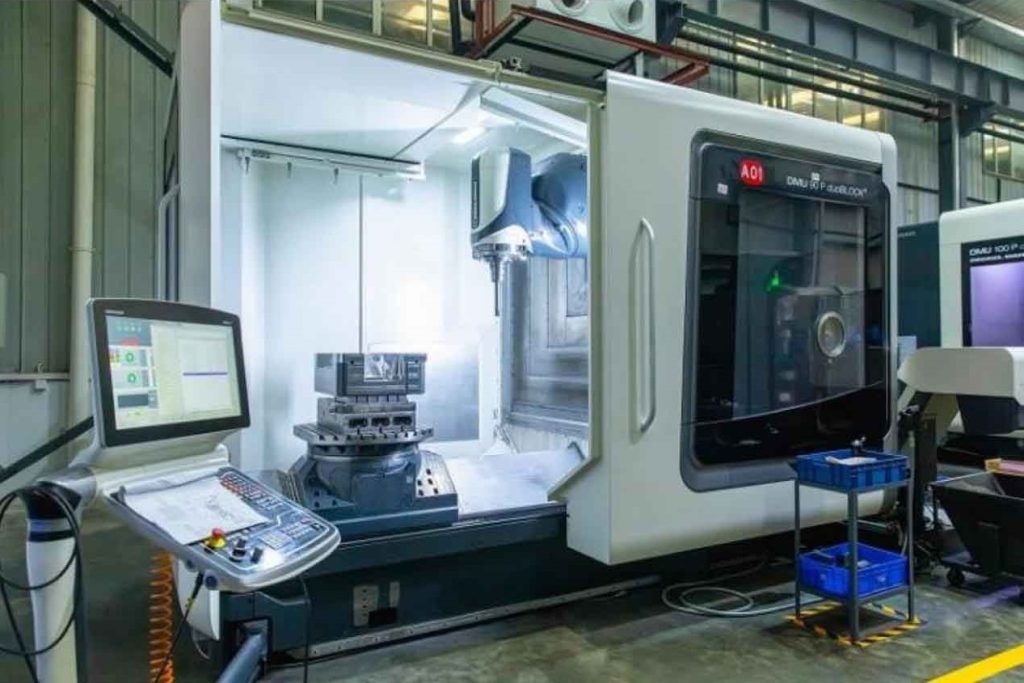

CNC machining center stands for a quite high-precision, high-efficiency automatic metal processing equipment, equipped with a multi-position turret or power turret, which is able to process linear cylinder, oblique cylinder, arc, and various thread, groove, worm, and other complex workpieces. it’s various compensation functions of linear interpolation and arc interpolation and has played an honest economic effect within the production of complex parts. However, any problem within the system, drive system, and therefore the electrical and system of the controlled object will cause the error problem. within the following guide, we briefly introduce the causes and solutions of the error within the CNC machining.

The Causes Of Errors In CNC Machining Center & the Ways to Fix

① In high-speed machining, there could also be errors like speeding up and down and servo system lag in the CNC system.

② thanks to the inertia of the system, drive system and therefore the electrical and system of the controlled object, dynamic errors like impact, vibration, overtravel, and out of step will appear when the acceleration is large.

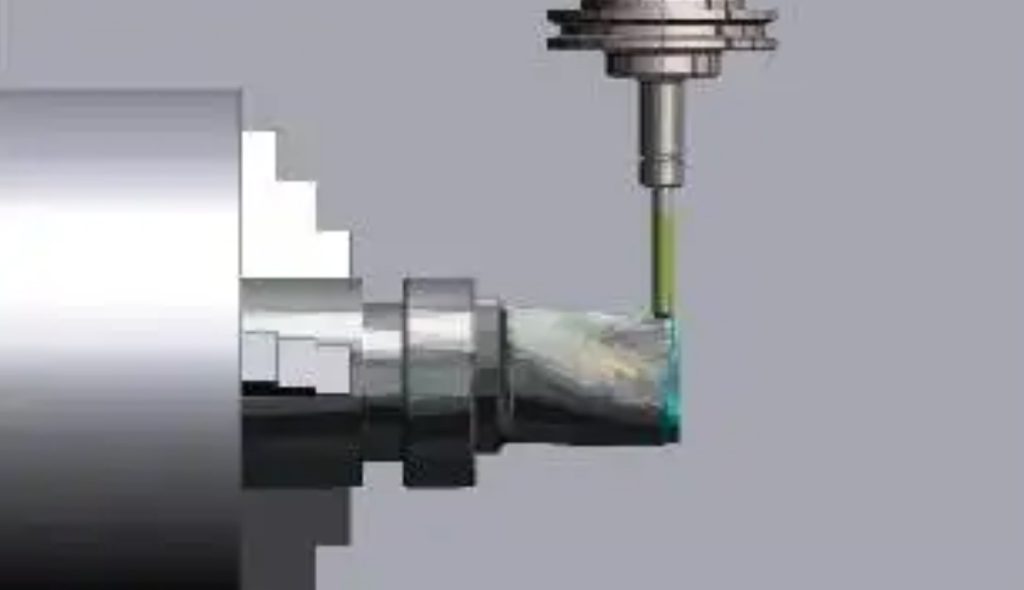

③ within the three-axis CNC end milling, the machining error consists of two factors: linear approximation error and normal vector rotation error;

④ The machining error is said to be the traditional curvature of the machined surface, the tool radius, and therefore the interpolation length, and is proportional to the square of the interpolation length.

⑤ Programming, tool selection, and human factors can also cause abnormal machining accuracy.

⑥ The rotation error of the normal vector is caused by the rotation of the normal vector of the machined surface along the direction of the interpolation line, and it’s proportional to the dimensions of the tool radius.

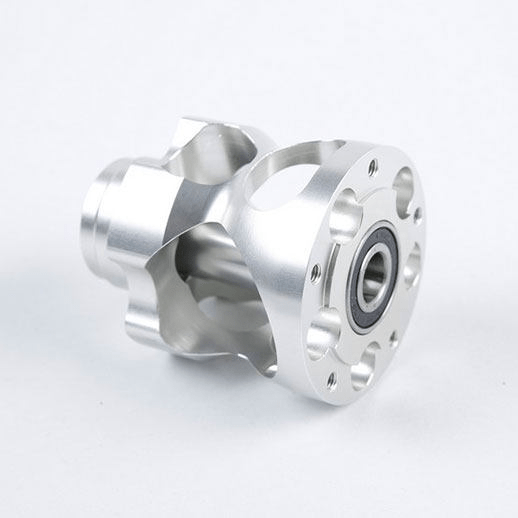

⑦ The accuracy error caused by the influence of tool material and cutting oil performance.

Solutions To Errors In CNC Machining Center

① the automated speed up and down of the numerical system is automatically realized by the software function of the numerical system. the essential requirement is that the chosen speed up and down law should make sure the trajectory accuracy and position accuracy, and make sure the rapidity, stability, and stability of the speed up and down process. At an equivalent time, the control algorithm should be as simple as possible and straightforward to be realized by a computer.

② For convex surface, the traditional vector rotation error is often compensated by modifying the tool center position, while for concave surface, no compensation is needed; When the system has no automatic compensation function, it adopts the tactic of reducing the tool radius to scale back the error.

③ The linear approximation error is decided by the interpolation chord length, which is said to be the interpolation cycle and therefore the tool feed rate of the numerical system. The linear approximation error is often controlled by selecting the numerical system with a smaller interpolation cycle or reducing the feed rate.

④ The residual height error of the cutting line is that the main factor affecting the surface roughness of the workpiece in curved surface machining. The error is often controlled by selecting reasonable cutting line width parameters.

⑤ The tool material and cutting oil of the CNC center can directly affect the wear and tear degree of the tool, and therefore the tool with fast wear will produce a large error to the workpiece. it’s helpful to enhance the accuracy of the workpiece to pick the corresponding tool and cutting oil for various processes.

The above is that the reason for errors in the CNC machining center, only by analyzing the mechanism of error can we take targeted measures to effectively improve the standard of the workpiece.