In the realm of manufacturing, the choice of casting method can significantly impact the quality, cost, and efficiency of product. Two widely used casting techniques, die casting and sand casting, offer distinct advantages and limitations. This article provides an in-depth comparison of die casting and sand casting, exploring their processes, advantages, limitations, and differences. Understanding the differences between these methods is crucial for customers choosing the suitable production methods.

What is Die Casting?

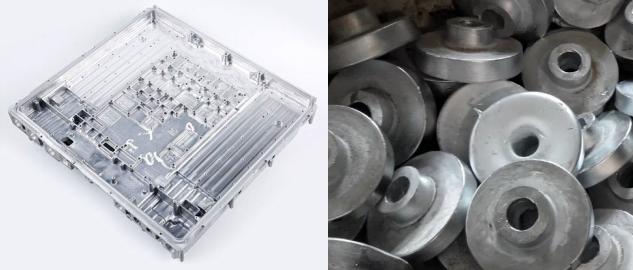

Die casting is a high-pressure metal casting process that utilizes a reusable metal mold, or die. Molten metal is forced into the die cavity under high pressure, creating a precise and repeatable shape.

Manufacturing Process of Die Casting

Die casting is a highly efficient manufacturing process used to produce metal parts with intricate shapes and high precision. The process involves forcing molten metal into a mold cavity under high pressure. Here’s an overview of the manufacturing process of die casting:

- Design and Mold Preparation:

The process begins with the creation of a detailed design for the part to be manufactured. This design may be generated using computer-aided design (CAD) software.

Based on the design, a mold, also known as a die, is created. The mold consists of two halves, the cover die and the ejector die, which are precision-machined from hardened tool steel.

- Mold Assembly:

The two halves of the mold are securely mounted on the die casting machine.

The mold is designed to allow for the flow of molten metal into the cavity and the ejection of the solidified part once the casting process is complete.

- Melting and Injection:

Metal ingots or pellets of the desired alloy are melted in a furnace at temperatures ranging from 1,300°C to 1,600°C, depending on the material being used.

Once the metal reaches the desired temperature and consistency, it is transferred to a holding furnace, where it is maintained at the proper temperature for the casting process.

The molten metal is then injected into the mold cavity at high pressure using a piston or plunger. The pressure forces the metal to fill the entire cavity and reproduce the intricate details of the mold.

- Cooling and Solidification:

After the mold cavity is filled, the molten metal begins to cool and solidify. The cooling time varies depending on factors such as the metal alloy, part size, and wall thickness.

Cooling channels integrated into the mold help regulate the temperature and ensure uniform solidification of the part.

- Ejection and Trimming:

Once the metal has solidified, the two halves of the mold are separated, and the casting is ejected from the mold cavity.

Any excess material, known as flash, is trimmed from the casting using shears or other cutting tools. The excess material is typically recycled for future use.

- Finishing Operations:

The castings may undergo additional finishing operations to remove any remaining imperfections, such as burrs or rough edges.

Surface treatments, such as shot blasting, sanding, or painting, may be applied to enhance the appearance and functionality of the parts.

Overall, die casting offers high production efficiency, tight tolerances, and excellent surface finish, making it a preferred choice for a wide range of industrial applications.

Advantages of Die Casting

Die casting offers several advantages that make it a preferred manufacturing process for producing metal parts with intricate shapes and high precision. Here are some of the key advantages of die casting:

- High Accuracy and Precision: Die casting allows for the production of parts with tight dimensional tolerances and complex geometries. The molds used in die casting are precision-machined, ensuring consistent and accurate reproduction of the desired shapes.

- Reproducibility: Once the die casting molds are created, they can be used to produce thousands or even millions of identical parts with minimal variation. This reproducibility ensures consistency in quality and performance across production runs.

- Reduced Machining Requirements: Die casting produces parts with near-net shape, minimizing the need for additional machining operations. This results in cost savings and reduced production lead times compared to other manufacturing processes that require extensive machining.

- Faster Production Cycles: Die casting is a high-speed manufacturing process, with cycle times typically ranging from seconds to a few minutes, depending on the size and complexity of the parts. This rapid production capability makes die casting well-suited for high-volume manufacturing applications.

- Wide Range of Materials: Die casting can be used with a variety of metal alloys, including aluminum, zinc, magnesium, and copper-based alloys. This versatility allows manufacturers to choose the most suitable material for their specific application requirements, balancing factors such as strength, weight, and cost.

- Enhanced Mechanical Properties: The rapid solidification of molten metal in the die casting process results in fine-grained microstructures with improved mechanical properties, such as strength, hardness, and wear resistance. This makes die-cast parts ideal for applications requiring structural integrity and durability.

- Complex Geometry: Die casting is capable of producing parts with intricate shapes, thin walls, and complex features, such as ribs, bosses, and internal cavities. This flexibility in design allows for innovative and lightweight component designs that may not be feasible with other manufacturing processes.

- Minimal Material Waste: Die casting is a near-net shape process, meaning that the amount of material required is closely matched to the final shape of the part. This results in minimal material waste compared to processes like machining, where significant amounts of material may be removed as chips or swarf.

Overall, die casting offers manufacturers a cost-effective and efficient solution for producing high-quality metal parts with complex geometries and tight tolerances. Its advantages make it a preferred choice for a wide range of industries, including automotive, aerospace, electronics, and consumer goods.

Limitations of Die Casting

While die casting offers numerous advantages, there are also some limitations associated with the process. Here are the key limitations of die casting:

- High Initial Tooling Costs: The production of die casting molds, also known as dies, involves precision machining of hardened tool steel. The initial tooling costs can be significant, particularly for complex parts or large production volumes. This can make die casting less economical for small-scale production or prototypes.

- Limited Material Compatibility: Die casting is primarily suited for metals with high fluidity at elevated temperatures, such as aluminum, zinc, magnesium, and certain copper-based alloys. Materials with lower fluidity or higher melting temperatures may be challenging to cast using this process, limiting the range of available materials.

- Complexity Limitations: While die casting is capable of producing parts with intricate shapes and complex features, there are limitations to the geometry that can be achieved. Parts with extremely thin walls, sharp corners, or complex internal geometries may pose challenges in terms of mold design, filling, and ejection.

- Part Size Constraints: Die casting is generally more suitable for small to medium-sized parts, ranging from a few grams to several kilograms in weight. Producing very large or heavy parts using die casting may require specialized equipment and tooling, increasing costs and complexity.

- Porosity and Gas Entrapment: During the die casting process, gases can become trapped within the molten metal, leading to the formation of porosity or air pockets in the final part. Porosity can weaken the structural integrity of the part and affect its mechanical properties. Proper venting and degassing techniques are essential to minimize this issue.

- Surface Imperfections: Die casting may result in surface imperfections such as surface porosity, flash, or parting lines. These imperfections can affect the aesthetic appearance of the part and may require additional finishing operations, such as grinding, polishing, or coating, to achieve the desired surface quality.

- Environmental Concerns: The die casting process typically involves the use of high-pressure equipment, molten metal, and energy-intensive operations, which can have environmental implications. Proper waste management and recycling practices are necessary to mitigate the environmental impact of die casting operations.

- Limited Design Flexibility: While die casting offers versatility in producing parts with complex geometries, there may be limitations in design flexibility compared to other manufacturing processes, such as additive manufacturing or investment casting. Design changes or modifications to the die casting mold can be costly and time-consuming.

Despite these limitations, die casting remains a widely used and highly effective manufacturing process for producing high-quality metal parts in various industries. Advances in technology and process optimization continue to address many of these limitations, expanding the capabilities and applications of die casting in modern manufacturing.

What is Sand Casting?

Sand casting is one of the oldest casting methods, dating back thousands of years. This traditional metal casting process that utilizes a mold created from compacted sand. Molten metal is poured into the sand mold cavity, where it solidifies.

Manufacturing Process of Sand Casting

Sand casting is a versatile manufacturing process used to produce metal parts of varying shapes and sizes. Here’s an overview of the sand casting process:

- Pattern Making:

The process begins with the creation of a pattern, which is a replica of the desired part.

Patterns can be made from various materials such as wood, plastic, or metal, depending on the complexity and requirements of the part.

- Mold Preparation:

The pattern is placed in a container known as a flask, which is divided into two halves: the cope (top) and the drag (bottom).

The pattern is pressed into a special molding sand mixture contained within the flask, creating an impression of the part in each half of the mold.

- Pattern Removal:

Once the sand has hardened around the pattern, the pattern is removed from the mold, leaving behind a cavity in the shape of the desired part.

- Core Making (Optional):

For parts with internal cavities or complex geometries, cores may be required to create these features.

Cores are made from sand or other materials and are placed in the mold cavity before pouring the molten metal.

- Assembly and Pouring:

The cope and drag halves of the mold are assembled, and any necessary gating and risers are added to facilitate the flow of molten metal and minimize defects.

Molten metal is poured into the mold cavity through the gating system, filling the space left by the pattern and cores.

- Solidification and Cooling:

Once the mold cavity is filled, the molten metal begins to solidify and cool, taking the shape of the part.

The cooling rate is controlled to ensure uniform solidification and prevent defects such as shrinkage or porosity.

- Mold Breakout:

After the metal has solidified, the sand mold is broken apart to reveal the casting inside.

The casting may require additional cleaning and finishing to remove any excess sand, gating systems, or other impurities.

- Finishing Operations:

Once the casting is removed from the mold, it may undergo additional finishing operations such as machining, grinding, sandblasting, or heat treatment to achieve the desired surface finish and dimensional accuracy.

Advantages of Sand Casting

Sand casting is a widely used manufacturing process that offers several advantages, making it suitable for producing metal parts of varying shapes, sizes, and complexities. Here are some of the key advantages of sand casting:

- Versatility: Sand casting is highly versatile and can be used to produce parts of almost any size and complexity, from small components to large industrial parts. Its flexibility allows for the production of intricate geometries, including internal cavities, undercuts, and thin-walled sections.

- Cost-Effectiveness: Sand casting is a relatively inexpensive manufacturing process, especially for low to medium production volumes. The materials used in sand casting, such as sand, clay, and binders, are readily available and affordable, contributing to lower overall production costs.

- Wide Range of Materials: Sand casting can accommodate a wide variety of metals and alloys, including ferrous and non-ferrous materials. Common metals used in sand casting include aluminum, iron, steel, brass, bronze, and magnesium. This versatility allows manufacturers to select the most suitable material for their specific application requirements.

- Tooling Flexibility: Unlike other casting processes that require complex and expensive molds or dies, sand casting molds can be easily modified or repaired, providing greater flexibility in design changes and iterations. This reduces lead times and costs associated with tooling adjustments.

- Low Equipment Investment: Sand casting equipment, such as molding boxes, pattern-making tools, and sand mixers, is relatively simple and inexpensive compared to other casting processes. This makes sand casting accessible to a wide range of manufacturers, including small-scale operations and foundries.

- Short Lead Times: Sand casting offers shorter lead times compared to other manufacturing processes, particularly for prototype or low-volume production runs. The relatively simple setup and minimal tooling requirements allow for faster production startup and turnaround times.

- Minimal Material Waste: Sand casting is a near-net shape process, meaning that the amount of material required is closely matched to the final shape of the part. This results in minimal material waste compared to processes like machining, where significant amounts of material may be removed as chips or swarf.

- Excellent Surface Finish: Sand casting can produce parts with a relatively smooth surface finish, especially when using high-quality molding sand and proper molding techniques. Post-casting finishing operations, such as shot blasting or tumbling, can further improve the surface quality of the parts.

- Suitability for Complex Geometries: Sand casting is capable of producing parts with complex geometries, including internal features and intricate shapes. By using cores and advanced molding techniques, sand casting can accommodate a wide range of design requirements, making it suitable for a variety of industrial applications.

Overall, the advantages of sand casting, including versatility, cost-effectiveness, wide material selection, and suitability for complex geometries, make it a preferred choice for many manufacturers across different industries.

Limitations of Sand Casting

While sand casting is a versatile and widely used manufacturing process, it also has several limitations that may affect its suitability for certain applications. Here are some of the key limitations of sand casting:

- Limited Dimensional Accuracy: Sand casting typically produces parts with lower dimensional accuracy and tighter tolerances compared to other casting processes such as die casting or investment casting. Variations in mold preparation, sand properties, and solidification can result in dimensional variations and inconsistencies in part dimensions.

- Surface Finish: The surface finish of sand castings is generally rougher compared to parts produced by other casting methods. The texture of the casting surface is influenced by factors such as the quality of the sand, mold preparation techniques, and the type of metal being cast. Additional finishing operations such as grinding, sanding, or shot blasting may be required to achieve the desired surface finish.

- Limited Complexity: While sand casting is capable of producing parts with relatively complex geometries, there are limitations to the complexity of shapes and features that can be achieved. Parts with intricate internal cavities, thin walls, or sharp corners may pose challenges in terms of mold design, sand compaction, and core placement.

- Porosity and Inclusions: Sand castings are susceptible to defects such as porosity, shrinkage, and inclusions, which can compromise the mechanical properties and integrity of the part. These defects are often caused by gas entrapment, inadequate venting, or improper gating and risering practices during the casting process.

- Low Production Rates: Sand casting is generally not as efficient as other casting methods in terms of production rates, especially for high-volume production runs. The process involves multiple steps such as pattern making, mold preparation, and casting, which can result in longer production lead times and lower throughput compared to more automated processes like die casting or investment casting.

- Environmental Impact: Sand casting can have environmental implications due to the generation of waste sand, dust, and emissions from sand preparation and casting operations. Proper waste management practices, including sand recycling and dust control measures, are necessary to minimize the environmental impact of sand casting operations.

- Tooling Wear and Maintenance: Sand casting molds and patterns are subject to wear and degradation over time, especially with repeated use. Maintenance and repair of molds, pattern equipment, and core boxes may be required to ensure consistent casting quality and dimensional accuracy.

Despite these limitations, sand casting remains a valuable manufacturing process for producing a wide range of metal parts, particularly for applications that prioritize cost-effectiveness, versatility, and flexibility in design. Advances in materials, process control, and automation continue to address many of these challenges, expanding the capabilities and applications of sand casting in modern manufacturing.

Difference Between Die Casting and Sand Casting

Die casting and sand casting are two distinct manufacturing processes used to produce metal parts, each with its own advantages, limitations, and applications. Here are the key differences between die casting and sand casting:

| Aspect | Die Casting | Sand Casting |

| Process Overview | Molten metal forced into precision-machined steel molds | Mold cavity created in sand using patterns or cores |

| Accuracy and Precision | Higher accuracy and precision | Lower accuracy and precision |

| Production Efficiency | Rapid production cycles, suitable for high-volume production | Longer production cycles, more suitable for low-medium volume |

| Tooling and Setup Costs | Higher initial tooling costs, lower long-term costs | Lower initial tooling costs, higher setup costs |

| Material Selection | Primarily non-ferrous metals | Wide range of metals and alloys |

| Complexity of Parts | Capable of producing complex geometries and tight tolerances | Limited complexity compared to die casting |

| Surface Finish | Smoother surface finish | Rougher surface finish |

This table provides a clear comparison of the key differences between die casting and sand casting across various aspects of the manufacturing processes. Overall, the choice between die casting and sand casting depends on factors such as production volume, part complexity, dimensional accuracy, surface finish requirements, material selection, and cost considerations. Both processes have their advantages and limitations, and manufacturers must carefully evaluate their specific requirements to determine the most suitable casting solution for their needs.

Conclusion

Die casting is ideal for high-volume production runs requiring precise dimensions, thin walls, and a good surface finish. However, the high initial cost and limited material selection can be drawbacks.

Sand casting excels in low-volume projects or situations where design flexibility and a wider range of materials are necessary. While sand castings require more post-processing, the lower initial cost makes them a viable option.

Ultimately, the best casting method depends on your project’s specific needs. By considering factors like production volume, part complexity, material requirements, and budget, you can make an informed decision between die casting and sand casting. Please feel free to contact casting service provider – JTR for suggestions.