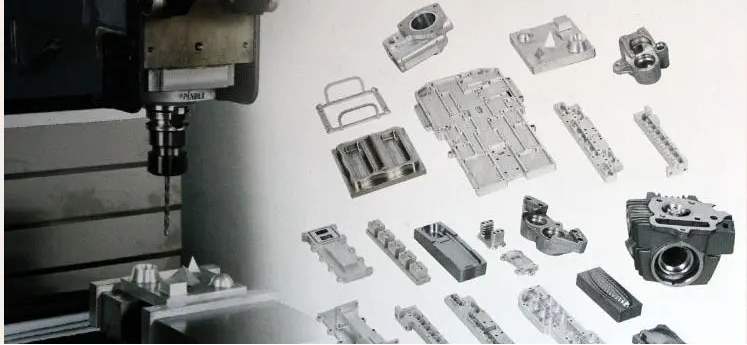

In the automotive industry, precision engineering is the cornerstone of producing high-quality vehicles with optimal performance and safety. One of the most crucial processes that exemplify this precision is CNC milling, which revolutionizes the manufacturing of auto parts. CNC (Computer Numerical Control) milling is a state-of-the-art technique that utilizes computerized controls to precisely remove material from a workpiece and create intricate shapes with tight tolerances. This article explores how CNC milling has become an integral part of automotive excellence by enabling the production of precise, reliable, and high-performance auto parts.

The Evolution of CNC Milling in Automotive Manufacturing

CNC milling has transformed the automotive manufacturing landscape, replacing conventional manual machining methods. In the past, producing auto parts involved laborious and time-consuming processes that often resulted in less consistent quality and higher costs. CNC milling, on the other hand, offers automation, repeatability, and efficiency, leading to improved productivity and enhanced component accuracy.

The Role of CNC Milling in Engine Components

- Cylinder Blocks: The heart of the engine

Precision machining for precise cylinder alignment and bore diameters

Creation of coolant passages and oil galleries for optimal engine cooling and lubrication

- Cylinder Heads: Enhancing engine performance

Accurate machining of combustion chambers and valve seats for efficient airflow

Ensuring proper sealing and compression within the engine

Transmission Components: Smooth Power Transfer

CNC milling is indispensable in the production of transmission components that contribute to smooth power transfer and seamless gear shifting.

- Gears: Precision machining for optimal performance

Accurate tooth profiles for smooth gear engagement

Reduced noise and increased efficiency in gear operations

- Shafts and Housings: Ensuring precise alignment and fit

Tight tolerances for reduced wear and improved transmission durability

Efficient power transfer between rotating components

Chassis and Suspension Parts: Stability and Handling

CNC milling plays a vital role in manufacturing chassis and suspension parts that ensure stability, handling, and overall ride comfort.

- Brackets and Mounting Plates: Strengthening the chassis

Accurate attachment points for structural integrity

Enhanced safety and load distribution in the vehicle frame

- Control Arms and Bushings: Enhancing Ride Quality

Precise geometry for optimal suspension performance

Smoother ride and improved handling characteristics

Steering and Brake Components: Safety and Control

CNC milling is instrumental in creating steering and brake components that directly impact safety and control in vehicles.

- Steering Components: Precise machining for accurate control

Proper alignment for responsive and predictable steering

Ensuring safe maneuverability and driver confidence

- Brake Components: Ensuring reliable braking performance

Accurate machining for even pressure distribution on brake pads

Consistent stopping power and reduced braking distances

Exhaust and Intake Systems: Optimal Engine Performance

CNC milling is essential in fabricating exhaust and intake components that optimize engine performance.

- Exhaust Manifolds: Improving engine efficiency and emissions

Efficient exhaust pathways for reduced backpressure

Contributing to increased engine power and reduced emissions

- Intake Manifolds: Enhancing airflow and engine efficiency

Smooth intake pathways for improved combustion

Maximizing engine power and fuel efficiency

Advancements in CNC Milling Technology

Continual advancements in CNC milling technology further enhance its capabilities and potential impact on automotive manufacturing.

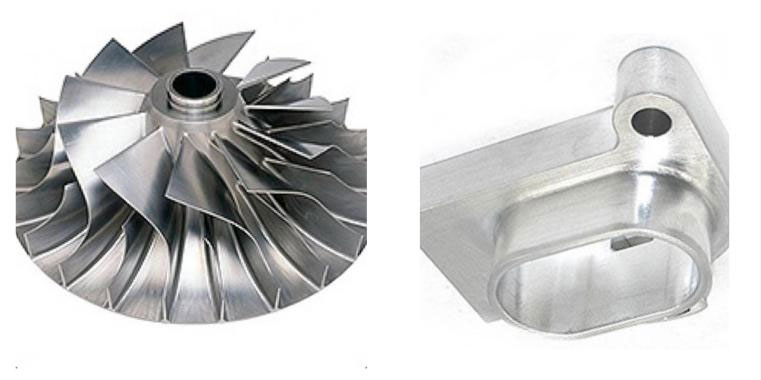

- Five-axis CNC Milling: Expanded machining possibilities

Creating complex shapes and geometries

Increased design flexibility and innovation in auto part production

- Hybrid Manufacturing Techniques: Combining additive and subtractive processes

Lighter and more efficient auto parts

Improved material utilization and reduced waste

- AI and Automation Integration: Streamlining production processes

Increased manufacturing efficiency and productivity

Enhanced quality control and reduced human errors

Conclusion

CNC milling has become the bedrock of precision engineering in the automotive industry, producing high-quality auto parts that contribute to automotive excellence. From engine components to transmission systems, chassis, and suspension parts, steering and brake components, as well as exhaust and intake systems, CNC milling plays an indispensable role in optimizing vehicle performance, safety, and overall driving experience. As technology continues to advance, CNC milling will continue to lead the way in achieving automotive excellence through precision engineering.