What Are the Five-Five Metal Casting Processes?

What Are the Five-Five Metal Casting Processes?

What Are the Five-Five Metal Casting Processes?

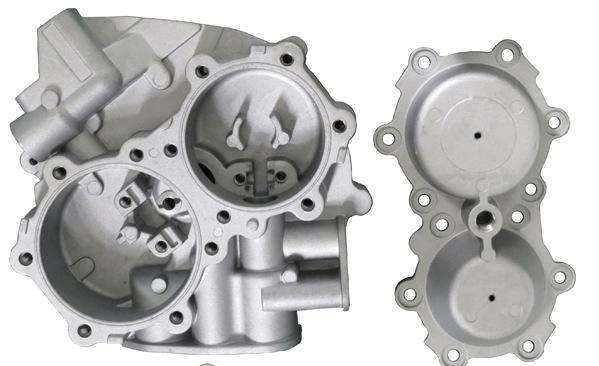

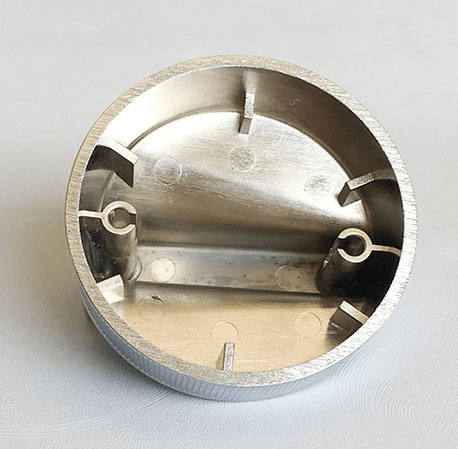

What Is the Best Casting Method for Automotive Parts?

The automotive industry has long relied on aluminum for its…

In the realm of manufacturing, the choice of casting method…

Generally speaking, the factors that affect the service life of…

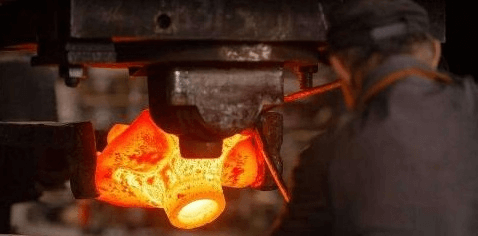

The concept of casting and forging The concept of casting…

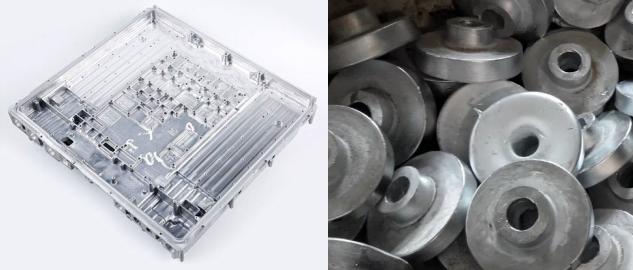

When people talk about the metal casting process, the words most often…

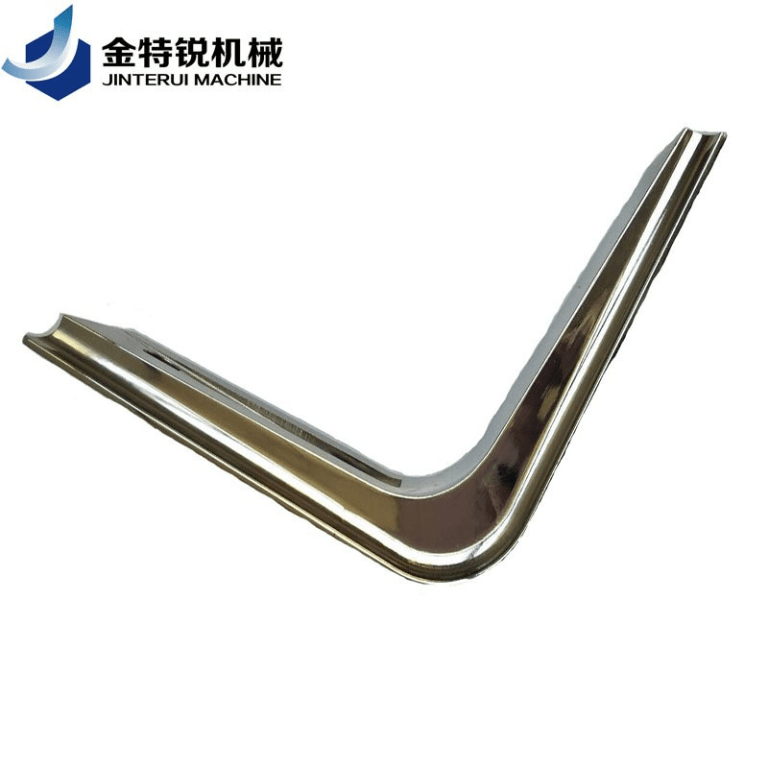

Metal stamping manufacturing processes can quickly and cleanly create solid metal…

We often hear the words casting and forging in mold…

Metal castings are the main supplier of blanks and spare…

Over its history, metal casting has been used to make…

Request A Quote