How Digitalization and Intelligence Upgrade CNC Milling and Turning

In the last 10 years, many industries around the world…

In the last 10 years, many industries around the world…

What Is the Hardest Material to CNC Machine?

What Is the Hardest Material to CNC Machine?

What Is the Hardest Material to CNC Machine?

What You Must Know Before Choosing CNC Machining Services

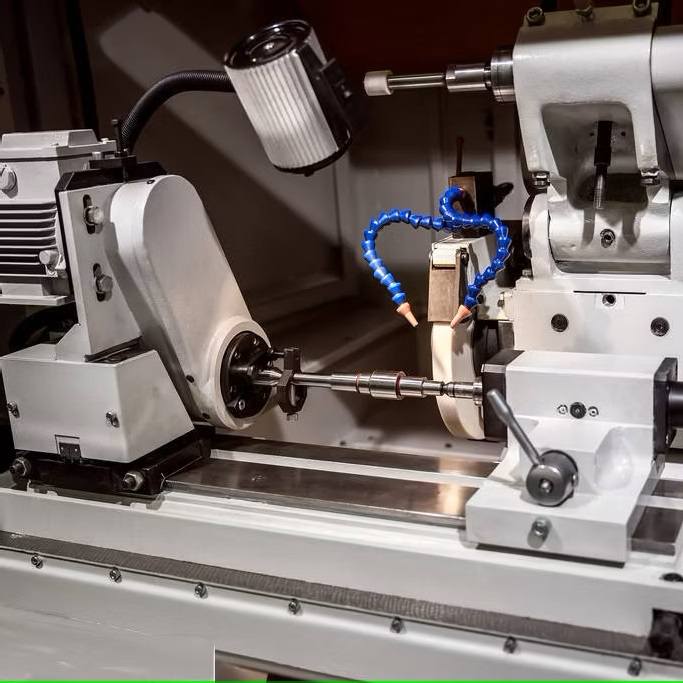

What is CNC Milling and Turning?

CNC (Computer Numerical Control) milling is one of today’s most precise and reliable machining processes. It is widely used in aerospace, medical, automotive, and electronics industries, where high precision is critical. But how precise is CNC milling, and what factors influence its accuracy?

Milled steel refers to steel that has undergone a milling process, where a rotating cutting tool removes material to achieve the desired shape, surface quality, and dimensional accuracy.

CNC milling is a vital process in modern manufacturing, delivering…

Carbon fiber has become a widely used material across industries…

CNC milling has revolutionized the manufacturing industry, enabling the production of…

CNC milling is a highly versatile manufacturing process, used across industries…

Request A Quote