How Different Casting Mold Materials Affect Part Quality

The selection of metal casting mold material is not merely…

The selection of metal casting mold material is not merely…

Crafting precision molds is critical for many manufacturing processes, enabling…

Mold making is a critical step in manufacturing, influencing production speed, cost, and overall product quality. But how long does it take to make a mold? The answer depends on mold complexity, material, manufacturing process, and customization requirements.

Mold making plays a crucial role in modern manufacturing, enabling the mass production of intricate parts across industries such as automotive, aerospace, medical devices, and consumer electronics. But can mold making accurately reproduce complex geometries with fine details, undercuts, and thin walls?

With the manufacturing industry’s escalating demand for rapid iteration and…

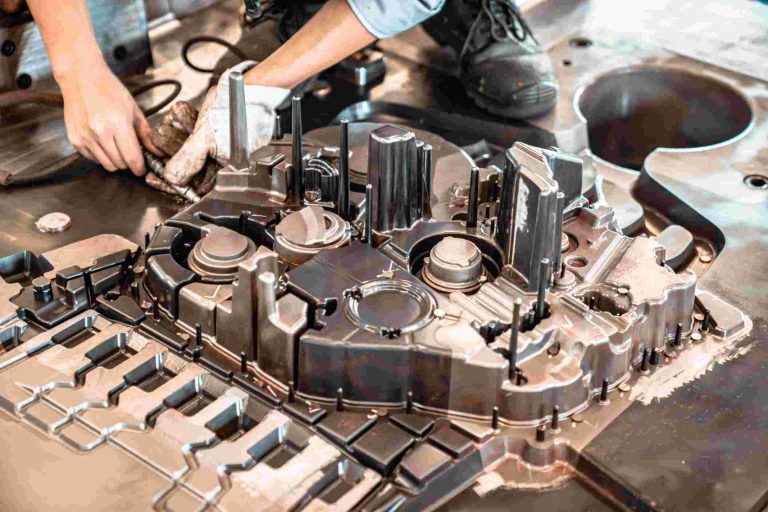

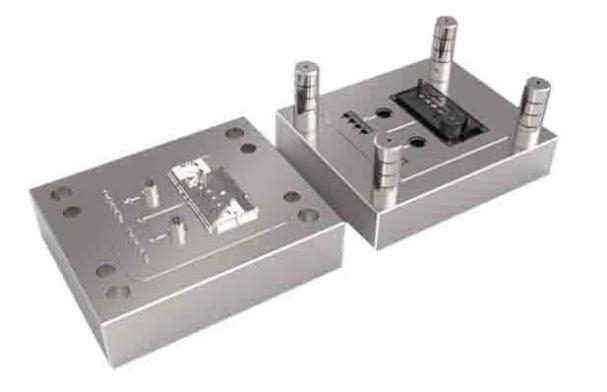

Die casting molds are at the heart of the die casting…

Molds are the backbone of many manufacturing processes, shaping plastic,…

With the continuous development of material technology, plastic products are…

In the production of tires, the tire mold is one…

When people talk about the metal casting process, the words most often…

The performance of the mold will be affected by the…

Traditional mold materials are divided into cold work mold materials,…

Request A Quote