From Steel to Aluminum: Comparing Six Common Sandblasting Metals

Sandblasting is one of the most effective surface treatment methods in modern…

Sandblasting is one of the most effective surface treatment methods in modern…

A perfectly polished mirror finish can turn an ordinary metal…

Aluminum mirror finishing is essential for applications demanding high reflectivity and…

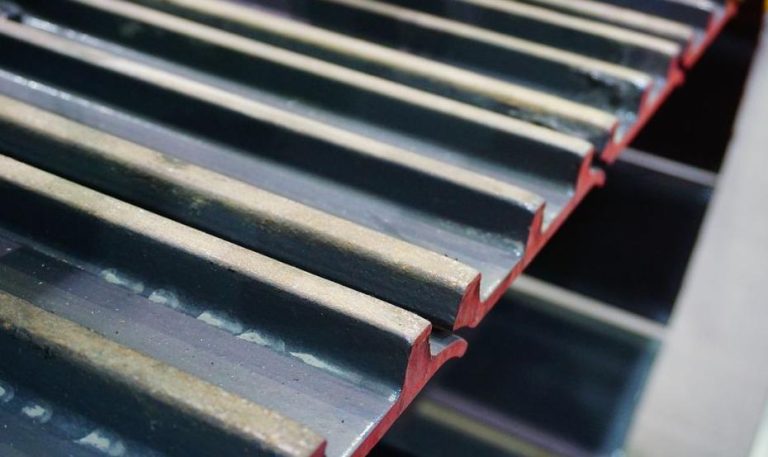

Steel, a ubiquitous material in modern construction and manufacturing, is…

Metal surfaces are prone to corrosion, scratching, and other forms…

Chrome finishing on aluminum is a process that enhances both…

Surface finishing is a critical aspect of product manufacturing, enhancing…

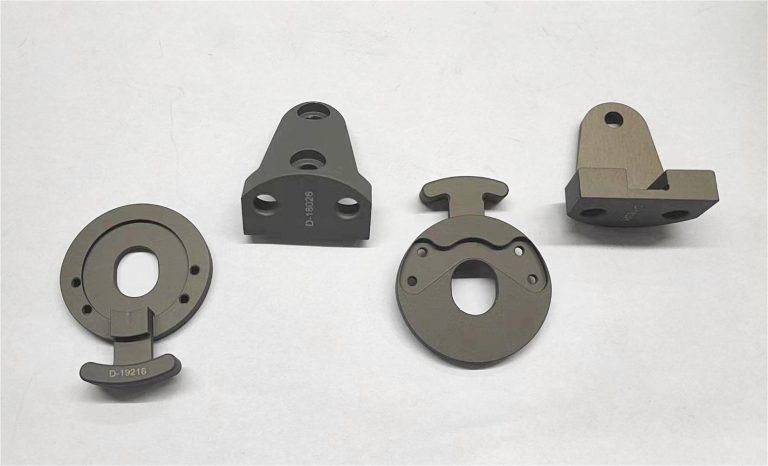

CNC machining is a versatile process that can create a wide…

Steel is a vital material used in countless applications due…

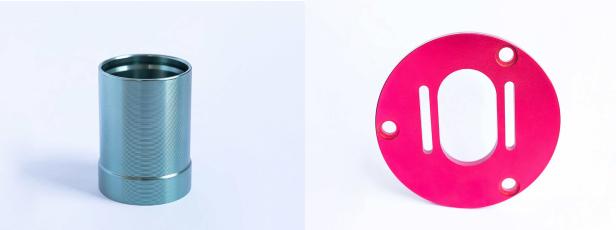

Clear anodized aluminum is a versatile material with a wide…

In the world of manufacturing and design, surface treatment plays a…

Anodizing is an electrochemical process used to strengthen and protect the…

Request A Quote