CNC Automotive Parts: 5-Axis Machining & Rapid Prototyping for High-Performance Vehicles

Today, precision, speed, and flexibility are even more essential in…

Today, precision, speed, and flexibility are even more essential in…

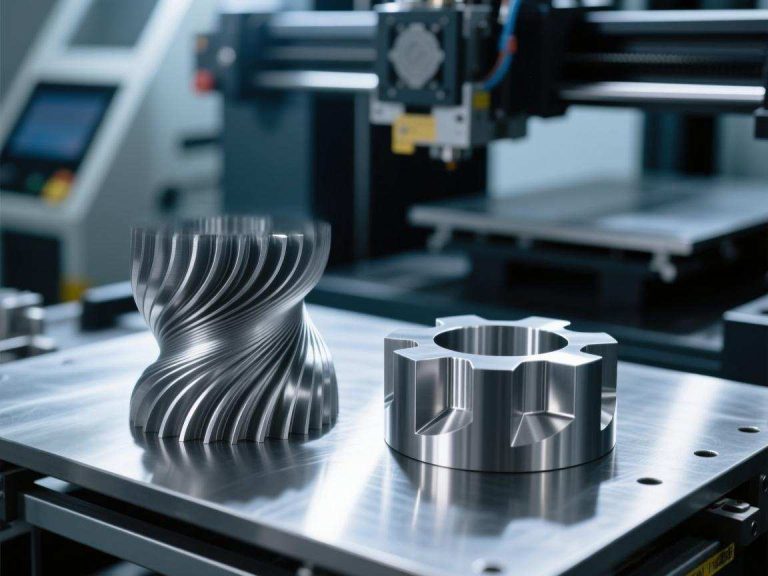

Automotive manufacturing once relied entirely on molds and assembly lines,…

Medical device manufacturing continues to push the bounds of precision,…

For procurement managers in the aerospace industry, few components carry…

The waste of material has always been a difficult problem…

In the medical sector, CNC machining is not just a step…

Due to their excellent strength-to-weight ratio, resistance to corrosion, and…

There is a serious change happening in global manufacturing right…

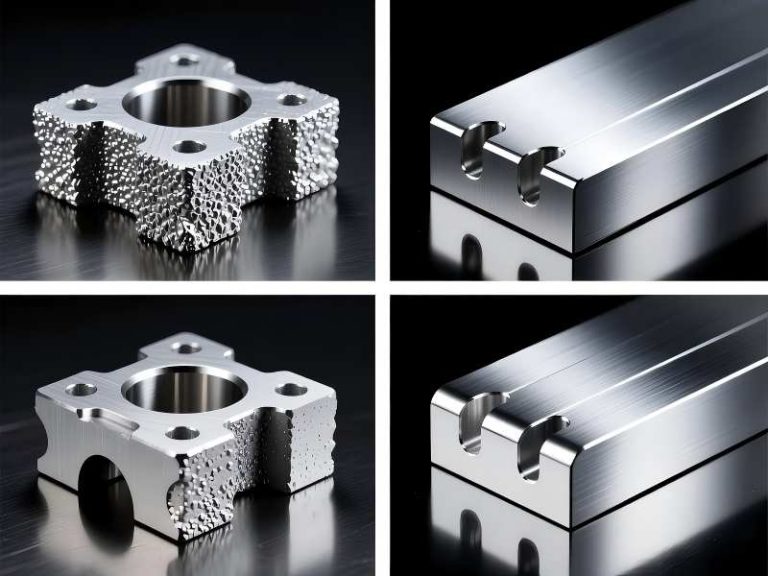

What Is the Hardest Material to CNC Machine?

What Is the Hardest Material to CNC Machine?

Every engineer working on precision parts has encountered a similar…

In the hyper-competitive world of consumer electronics and industrial devices,…

Request A Quote