What Are the Differences Between Wire EDM and Die-Sinking EDM?

Wire EDM erodes metal with a precise, continuous wire, similar to…

Wire EDM erodes metal with a precise, continuous wire, similar to…

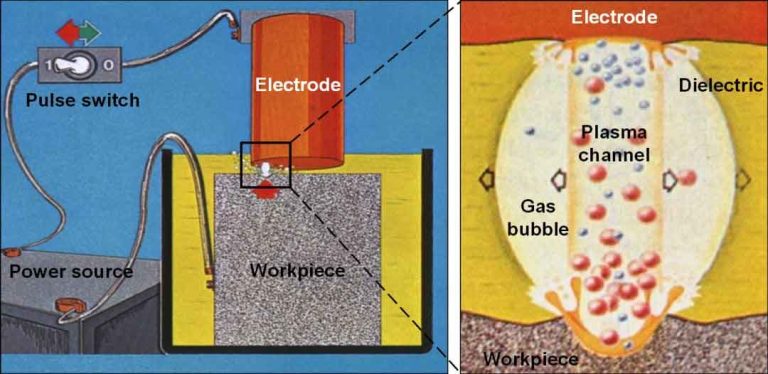

Wire electrical discharge machining (Wire EDM) is a non-traditional machining process…

In the realm of modern manufacturing, precision cutting and shaping…

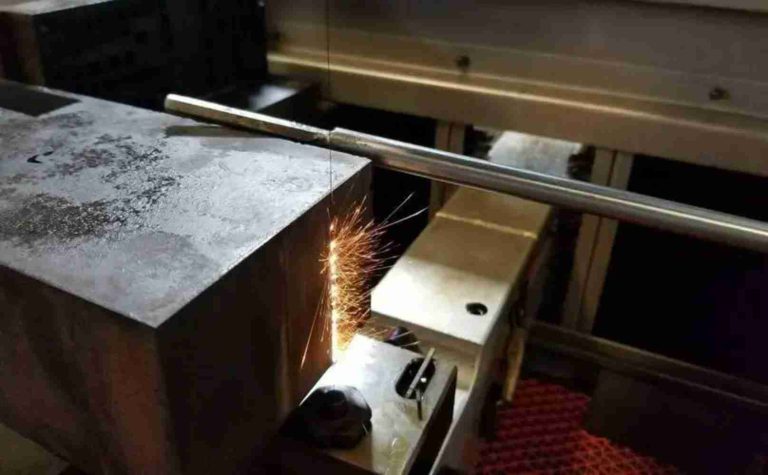

Wire EDM, also known as wire cutting, uses continuously moving…

Maybe you are exposed to EDM daily in production, but…

If you want to CNC machining titanium, people often need more time…

For workpieces with complex structures, traditional cutting methods are often…

In recent years, there has been a voice in the…

At present, the electrode wire EDM used in domestic fast wire cutting…

Request A Quote