Making three-dimensional solid products from digital data is known as additive manufacturing, sometimes known as 3D printing. 3D printers now offer technology and production capabilities that are accessible to the general public. You can use a single printer to produce a variety of designs using a variety of materials.

What is 3D Printing?

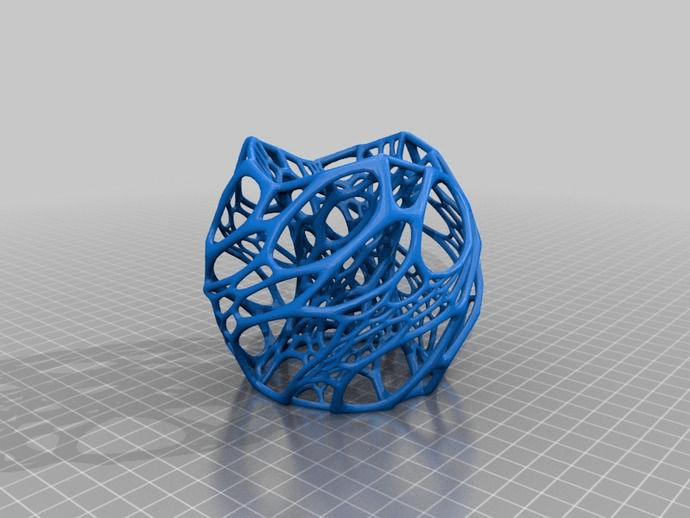

3D printing is the use of additive methods to produce 3D-printed objects. In the additive process, objects are created by adding material layer by layer until the final product is produced. is generated by the continuous superposition of finely sliced cross-sections of the object. With 3D printing, you can create intricate shapes with less material than with conventional production techniques.

Currently, 3D printing is not fast enough for mass production. It may, however, efficiently cut costs and shorten the time between product design and finished product production, making it perfect for accelerating the development of the production process.

Since 3D printing technology was developed, production efficiency has grown. Long-term effects on the manufacturing sector may result from its effective subsequent integration into a mass production process.

Processes of 3D Printing

A 3D printer operates similarly to a 2D printer. When you use word processing software, the printer “prints” out a pattern as directed by the software using liquid ink, replicating your text. Here’s a simplified explanation of the process:

- Designing the Model: The first step in 3D printing is creating a digital 3D model of the object you want to print. This can be done using computer-aided design (CAD) software or by downloading existing models from online repositories.

- Slicing: Once the 3D model is created, it needs to be sliced into thin horizontal layers using slicing software. You can send files to your printer using USB, SD, or Wi-Fi. Each layer is then translated into instructions for the 3D printer.

- Setting Up the Printer: Before printing can begin, the 3D printer needs to be prepared. This involves loading the appropriate material (such as plastic filament, resin, metal powder, etc.) into the printer and ensuring that it is properly calibrated.

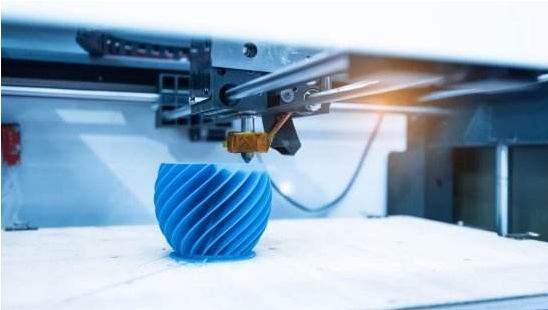

- Printing: The printing process begins, with the 3D printer following the instructions generated by the slicing software. The printer deposits material layer by layer, gradually building up the object from the bottom up. The specific printing technique and material used will depend on the type of 3D printer being used.

- Cooling and Post-Processing: Once the printing is complete, the object may need to cool down before it can be removed from the printer. Depending on the material and printing process, post-processing steps such as removing support structures, sanding, polishing, or painting may be necessary to achieve the desired finish.

- Quality Control: After post-processing, the printed object should be inspected for any defects or errors. This may involve visual inspection, measurements, or testing to ensure that the object meets the desired specifications.

Overall, 3D printing is a versatile manufacturing technology that allows for the creation of complex shapes and geometries with relatively low cost and fast turnaround times compared to traditional manufacturing methods. It is used in a wide range of industries, including aerospace, automotive, healthcare, and consumer goods.

Main Types of 3D Printing Technologies

There are several types of 3D printing technologies, each with its advantages and disadvantages. The best technology for a particular project will depend on the desired material, finish, accuracy, and strength. Here are the main types:

Here’s a brief rundown of the most common types of 3D printing technologies:

Fused Deposition Modeling (FDM): FDM is the most common type of 3D printing technology. It works by extruding a filament of molten plastic through a heated nozzle, building the object layer by layer. FDM is a versatile and affordable option, but the parts can have a rough surface finish and may not be as strong as parts made with other technologies.

Selective Laser Sintering (SLS): SLS uses a laser to selectively sinter (fuse) particles of plastic, metal, or ceramic powder together. SLS is a good option for creating strong, functional parts, but the parts can be somewhat rough and require post-processing.

Stereolithography (SLA): SLA uses a vat of liquid resin and a laser to cure the resin layer by layer, building the object from the bottom up. SLA is known for its high accuracy and smooth surface finish, making it ideal for creating detailed prototypes and models.

Digital Light Processing (DLP): DLP is similar to SLA but uses a projector instead of a laser to cure the resin. DLP printers are generally faster and more affordable than SLA printers, but the parts may not have the same level of detail or smoothness.

Applications of 3D Printing

3D printing has revolutionized many industries due to its versatility and ability to create complex objects. Here are some of the widespread applications of 3D printing:

| Industry | Brief Description | Specific Representative Parts |

|---|---|---|

| Manufacturing | Prototyping, creating jigs and tools, and even some end-use parts | Concept models, functional prototypes, casting molds, jigs and fixtures, low-volume production parts |

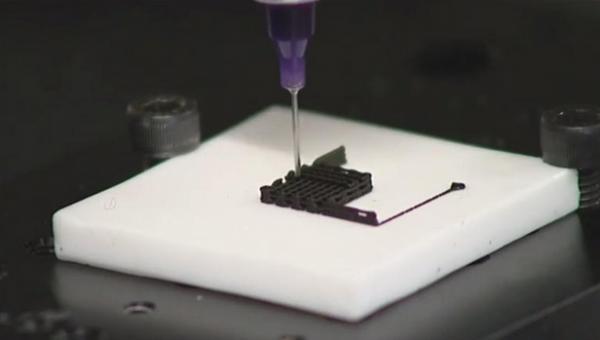

| Medicine | Surgical planning, prosthetics, dental applications, and implants | Anatomical models, custom prosthetics, dental aligners, bioprinting for tissue engineering |

| Architecture | Creating scale models and complex architectural components | Building scale models, customized facades, complex interior features |

| Custom Art & Design | Personalized creations, prototypes, and models | Sculptures, figurines, custom jewelry, design prototypes, architectural models |

| Education | Bringing student designs to life and enhancing learning | Engineering models, scientific demonstration models, historical artifacts |

These are just some of the many applications of 3D printing. As the technology continues to develop, we can expect to see even more innovative uses emerge in the future. If you need 3D printing, please contact JTR.