How to Know Whether 3D Printing is The Best Manufacturing Process for Your Parts?

2019 is THE YEAR for 3D printing. For the first time, it is believed to be a manufacturing process instead of just a model making technology. The fact is, before 2019, 3D printing is often called Rapid Prototyping for its use. But here we are now, millions of products are being produced through this exciting epoch-making technology. So you might wonder that if your product can be processed by it too. Yes, this manufacturing process (being confident to call it a process now) is able to handle even the most complex components. But still, you should consider it thoroughly before a decision. In this article, I’ll list some of the basic ideas you should know before you choose 3D printing to be the manufacturing process for your parts. Stay tuned.

What is 3D Printing?

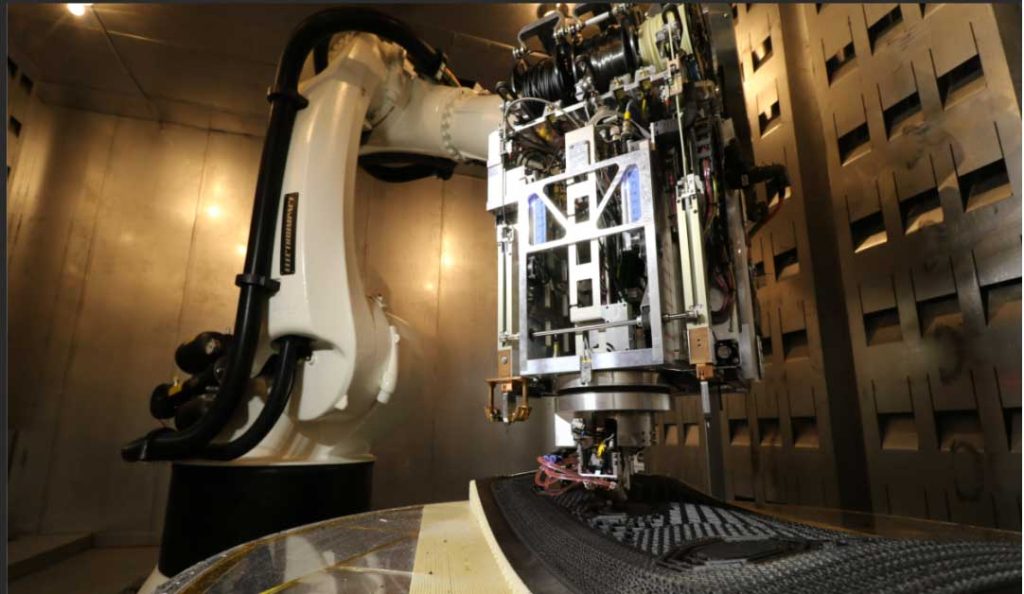

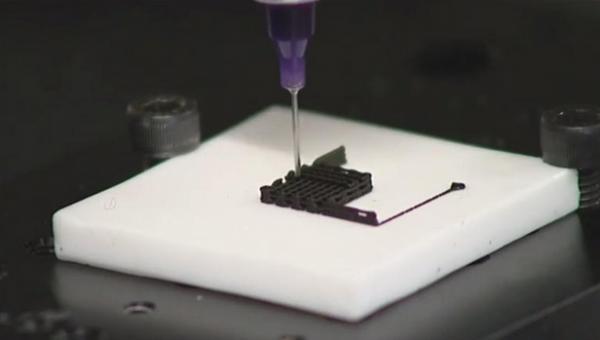

3D printing is actually a synonym for additive manufacturing – a manufacturing process that produces three-dimensional parts/models by “additively” depositing different materials layer by layer. The whole process is under the control of a computer program which is very similar to CNC machining.

How Does 3D Printing Work?

It is said that the person who invented 3D printing was inspired by the idea of how underground stone forms its own unique formation, and 3D printing truly appears to be like creating a rock out of nothing. But if you take an observation on the process, you will find a nozzle ejecting materials layer by layer and gradually forms a shape. That’s how a 3d printer works in the level of mechanical. To achieve those mechanical operations, the computer program needs to decompose a three-dimensional design into a great number of two-dimensional layers. Then, instructions are given to the numerically controlled nozzle which would “print” those layers one by one afterward.

The above is the general idea of 3D printing, but in actual cases, the process can vary for different materials or other requirements.

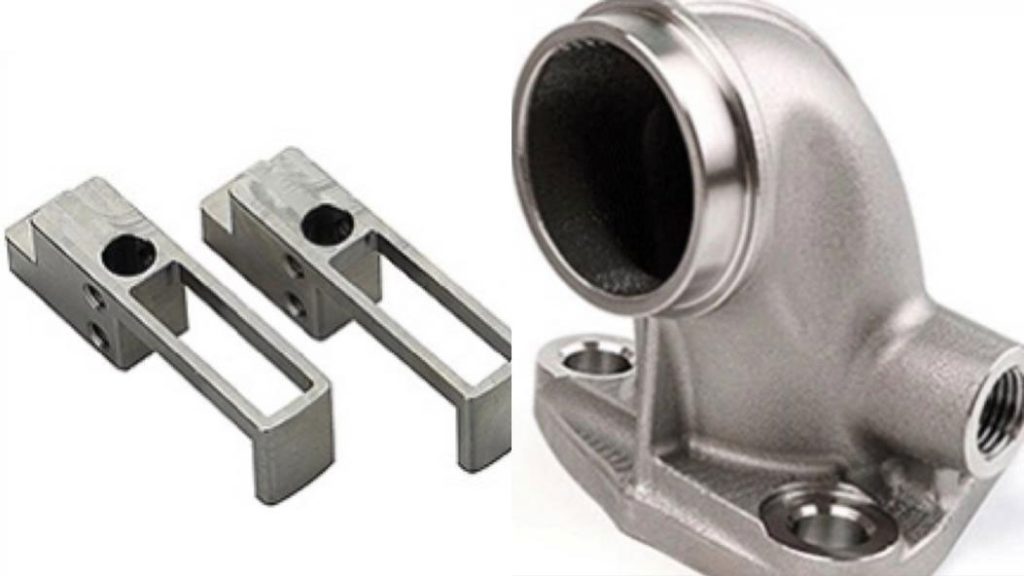

For a very long time, the most commonly used materials for 3D printing are plastic and polymers because they are relatively easy to melt. Moreover besides, it was just so costly back then. But as this tech keeps updating itself, metal and even ceramics can also be processed by this highly demanding method to create parts or models. The maturity of technology has also greatly reduced costs. 3D printing finally has its versatility and value for money, demonstrating that it’s ready to go into large-scale industrial applications.

How is 3D Printing Compared to CNC Machining? Pros And Cons

Speaking of large-scale industrial applications, you might be reminded of CNC Machining. Yep, it’s probably the process you’d choose in most cases when you got some parts to produce. So as a rookie in many industries, how is 3D printing compared to CNC machining? Below I’ve created a table to help you compare those two manufacturing processes and find out the Pros and Cons of 3D printing.

| FeaturesProcesses | 3D Printing | CNC Machining |

| Additive or Subtractive | Additive | Subtractive |

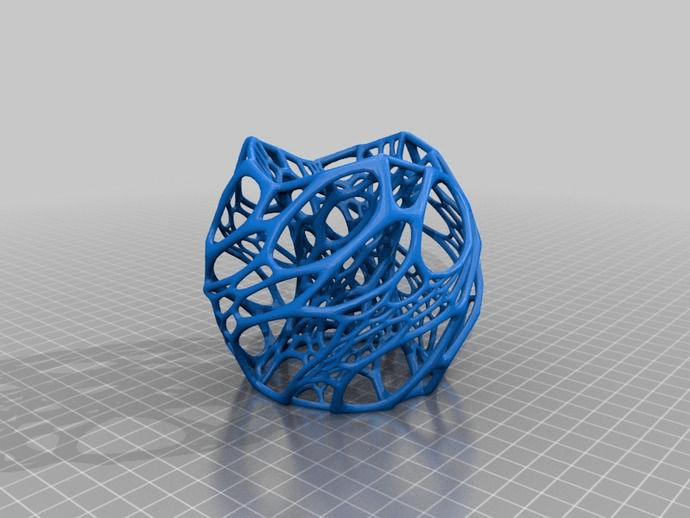

| Ability to manufacture complex parts | Able to manufacture complex parts that are hollow or with internal truss structures | Able to manufacture complex parts but can not process hollow parts or parts with internal structures |

| Precision | High precision | Very high precision |

| Material versatility | General material versatility | High material versatility |

| Production speed | Very fast | Medium speed |

| Use of tools | One tool for all materials and processes | Multiple tools for different materials or processes |

| Cost-efficiency | Low for big volume medium for small volume | Medium for big volume low for small volume |

| Skill requirement | High | Medium |

3D printing shows its Pros and Cons as a newly invented tech – higher cost and skill requirement for a higher degree of product complexity and production speed. We also realized that 3D printing is probably the best solution for rapid prototyping, while still needs improvement as a mass production manufacturing process. When you are trying to figure out which one is better for your product, take those factors into consideration.

Why is 3D Printing So Expensive?

No matter you take it to the 3D printing service factory or buy your own 3D printer, it’s not gotta be a small expense. Compared to those less advanced techs like manual production and CNC machining, 3D printing often costs more. I’ll list some reasons why it is so expensive for you to measure whether it’s worth it.

1. Unsurpassed production speed

One thing that 3D printing got famous for is its production speed. In some cases, rapid prototyping for your parts can take even less than half an hour. Most 3D printing service company have shortened their lead time to within one day (for prototyping or low volume production), which is unsurpassed for traditional forming technologies.

2. High degree of product complexity

3D printing can create parts with internal structures. If you got special needs for your product, you should turn to it.

3. Higher capital costs

An industrial 3D printer can cost thousands of dollars, resulting in a much higher capital cost than other manufacturing processes.

4. Design incompatibility

At present, most three-dimensional parts are designed on the basis of traditional manufacturing techs. The fact is, if you design your parts the way 3D printing can be applied more easily, the cost will be reduced by a certain amount.

5. Materials

Materials used in 3D printing often need extra processing, thus raising the cost.

Is It Worth Buying A 3D Printer?

We know that 3D printing service can be costly, so you might be thinking about purchasing your own 3D printer and do all the works yourself. While, it’s not wrong. But you need some analysis before turning to a sales consultant.

For industrial uses, the cost of a 3D printer can be huge, and you’d also need an operator (which means extra labor costs). If you’re doing this only to make some of your own parts instead of going into the parts processing business. I might suggest you shake it off.

There are some other models of 3D printers that cost only a few hundreds of dollars. And these little machines are mostly for personal or small business uses (by which I do not mean the recently discussed house-making machine, that big guy might cost more than I can imagine). If you’re just considering making your own anime figures, it could be an option.

How to Choose The Right 3D Printing Service for Your Parts?

There are not many companies currently providing 3D printing service globally, so each of them might have its own unique machine configuration and process. No widely accepted industry standard for now. You’d got to figure out whether the company is capable of processing your uniquely designed parts. You got compare their lead time, prices, tolerance, quality, etc. So, in my opinion, just find the service, upload your file and get a quote. It is free to quote anyway. 3D printing is a service JTR Machine provides, too. If you’re interested, feel free to contact us and get a quote.