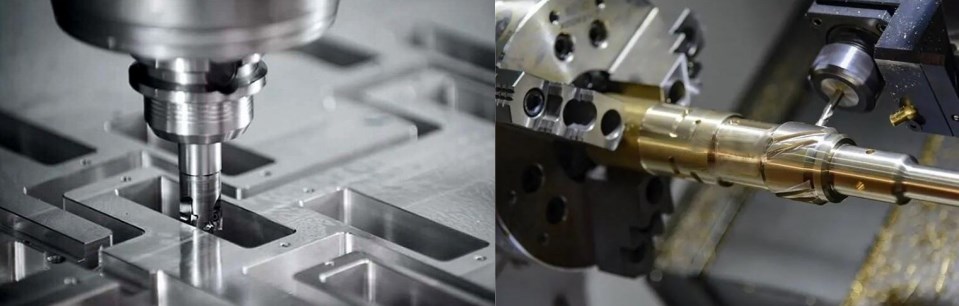

Precision CNC Turning Parts SS304 or Bronze

- Material: Stainless Steel、Bronze

- Size: Φ35*104mm、Φ66*19mm

- Process: CNC turning、CNC milling

- Surface Treatment: None

Description

Available Materials for JTR Precision CNC Turning

| Aluminum Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc. | Steel Mild Steel, Alloy Steel, etc. | Plastic PET / PVC / ABS / PC / PE / PTFE / POM / PMMA / Nylon / PP / Peek, etc. |

| Cooper C11000 / C12000 / C12000 / C36000, etc. | Stainless Steel Stainless-steel 303 / 304L / 316L / 416 / 440C | Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc. |

CNC turning service can be applied to a great number of materials, such as metal, plastic, and wood. Each turning material needs different lathes. according to the types of materials machined, certain maintenance and safety precautions may be needed for the lathe. Above are some common materials JTR can offer to work on. Other materials or custom-sourced materials are available, get a quote and we can start right away!

Advantages of CNC Turning Stainless Steel Parts

- Precision: CNC turning machines can achieve high levels of precision and accuracy, making it possible to create intricate and complex shapes in stainless steel. This is crucial for industries like aerospace and medicine, where tight tolerances are required.

- Consistency: CNC turning ensures consistent quality in each produced part, reducing variability and minimizing the risk of defects. This is essential for maintaining product integrity.

- Versatility: CNC turning can be used to create various shapes and sizes of stainless steel parts, from simple shafts to more complex components like valves, fittings, and connectors.

- Efficiency: CNC turning is a highly efficient process, which can reduce production times compared to manual machining methods. This efficiency is particularly valuable for high-volume production runs.

- Reduced Waste: CNC turning generates less waste material compared to some other machining methods, as it optimizes the cutting path, resulting in cost savings.

- Material Compatibility: Stainless steel is a corrosion-resistant material often used in applications where durability and resistance to harsh environments are critical. CNC turning can handle stainless steel effectively.

Advantages of CNC Turning Bronze Parts

- Self-Lubricating Properties: Bronze is known for its self-lubricating properties, making it an excellent choice for bearing and bushing applications. CNC turning can precisely create these components to meet specific requirements.

- Wear Resistance: Bronze exhibits good wear resistance, which is advantageous in applications where parts are subjected to friction and wear, such as in the automotive and industrial sectors.

- Machinability: Bronze is generally easier to machine compared to some other metals, making it well-suited for CNC turning. It can be cut, drilled, and turned with relative ease.

- Heat Dissipation: Bronze is a good conductor of heat, making it suitable for applications where heat dissipation is crucial, such as in electrical connectors and heat sinks.

- Corrosion Resistance: Bronze is resistant to corrosion, making it suitable for use in marine and underwater applications.

- Aesthetic Appeal: Bronze has a distinctive appearance, with a warm, coppery color that is often valued for decorative and architectural applications. CNC turning can shape bronze into intricate designs.

CNC turning offers precision, consistency, and efficiency when machining both stainless steel and bronze parts. These advantages are valuable in various industries and applications, ranging from aerospace and automotive to marine and decorative uses. However, specific considerations and tooling may be necessary for each material to optimize the CNC turning process and achieve the desired results.

Why Choose JTR For Precision CNC Turning?

JTR has many choices for CNC turning service, we can not only provide you the fine quality of our products but also the best service, our sophisticated engineering team will offer you a perfect turning plan, for the quality of our products, we also ensure you with our ISO9001:2008 and TS16949 quality system certificates. We will try our best to make the production within 1 day, then the products will be sent to your door as fast as we can.