What Types of CNC Machine Tools are There?

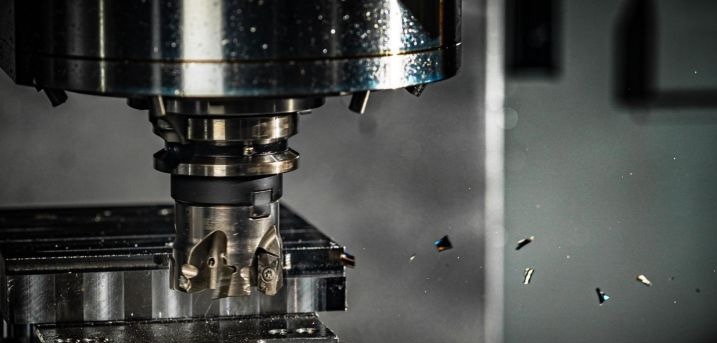

A CNC machine tool is an automatic machine tool equipped…

A CNC machine tool is an automatic machine tool equipped…

Like all things, having multiple options is usually a good…

CNC machining occupies a very high position in CNC equipment….

With the development of science and technology, people have put…

If you want to CNC machining titanium, people often need more time…

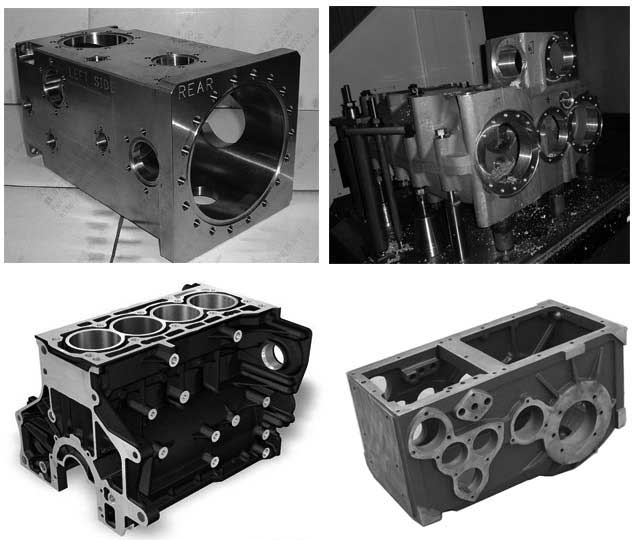

CNC machine tool is a digitally controlled machine tool. Its…

This article will discuss the current development trend of Numerical…

Compared with external surface processing, the conditions of CNC machining…

The development and application of numerical control technology make machining…

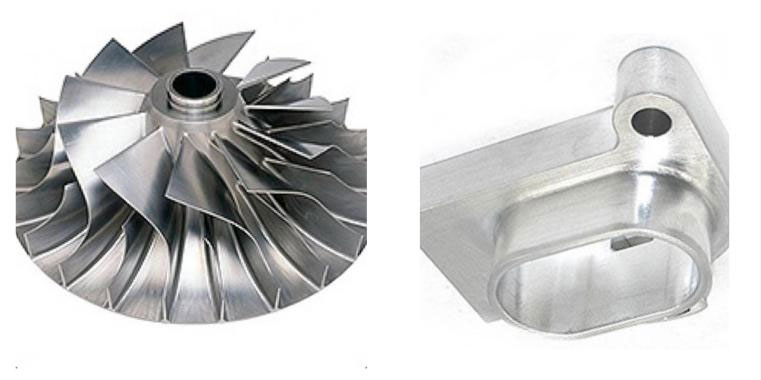

In the realm of manufacturing, precision parts play a pivotal…

At present, the mechanical processing industry and CNC machining industry have…

In recent years, with the rapid development of CNC machining,…

Request A Quote