Choosing the right finish for your project can be challenging. With so many options available, it’s critical to understand the benefits and drawbacks of each to make an informed decision. Anodizing and painting are two popular finishing options for metal surfaces. But what are these processes and how do they differ? Let us delve into the world of metal finishing and examine the key differences between anodizing and painting.

The Key Differences Between Anodizing and Painting

| Anodizing | Painting | |

| The Process | Electrochemical, thickens natural oxide layer | Physical application of liquid paint |

| Durability & Scratch Resistance | Excellent, hard & integral part of metal | Good to excellent, depending on the paint quality |

| Corrosion Resistance | Excellent, protects metal from most environments | Good to excellent, depending on paint quality & adhesion |

| Appearance | Limited color options, metallic finishes, matte to glossy | Wide range of colors & textures, including gloss, matte, metallic |

| Maintenance & Repair | Low maintenance, easy to clean | Regular cleaning, touch-up painting for scratches |

| Cost | Higher initial cost | Lower initial cost, but may require repainting |

Difference 1: The Process

Anodizing is an electrochemical process that increases the thickness of aluminum’s natural oxide layer. It entails immersing the metal in an electrolyte solution and delivering a current. This process produces a hard, durable, and corrosion-resistant oxide layer that becomes a part of the aluminum itself. Painting is a more traditional way to apply decorative and protective coatings to a surface. It consists of applying a liquid paint mixture to the metal, which then dries and forms a film on top.

Difference 2: Durability and Scratch Resistance

Anodized aluminum outperforms paint in terms of scratch and abrasion resistance. The oxide layer is integrated into the metal, making it extremely durable and resistant to wear and tear. Paint can be scratched or chipped fairly easily, depending on the type and quality of paint used. Scratches can expose the underlying metal, leaving it vulnerable to corrosion and jeopardizing the overall appearance.

Difference 3: Corrosion Resistance

The integral oxide layer formed during anodizing offers excellent corrosion resistance to aluminum. This makes it ideal for use in applications where the metal is subjected to harsh elements or chemicals. While some paints provide adequate corrosion protection, they may chip or crack over time, exposing the metal and allowing corrosion to occur. In addition, the paint itself can corrode in certain environments.

Difference 4: Appearance

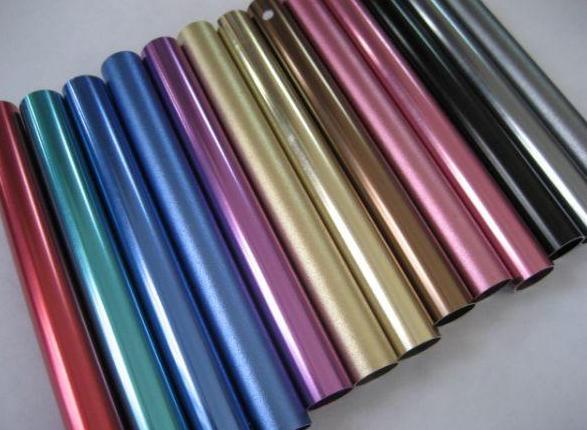

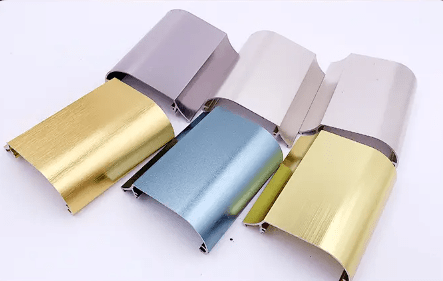

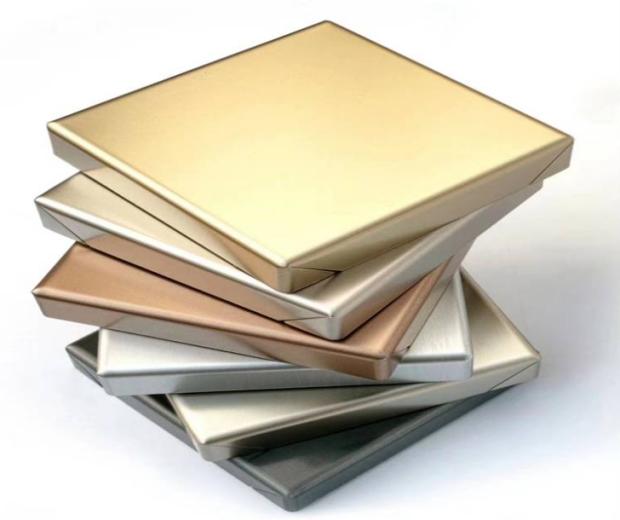

Anodizing can produce a wide range of finishes, including clear, matte, glossy, and even bright colors. The color is created by varying the thickness of the oxide layer or incorporating dyes into the process. However, the color palette is generally limited when compared to paint. Paint has a wide range of color options and finishes, allowing for more customization and creative expression. Paint allows you to create almost any color or texture you can imagine.

Difference 5: Maintenance and Repair

Anodized surfaces are generally low-maintenance and simple to clean. They require little maintenance and can be cleaned with mild soap and water. Scratches on anodized aluminum are difficult to repair and frequently necessitate re-anodizing the entire surface. Painted surfaces require more frequent cleaning and maintenance to keep their appearance. Scratches and chips can be painted over, but the repair may not be seamless and may necessitate professional assistance for a perfect match.

Difference 6: Cost

The cost of anodizing varies according to the project’s size and complexity, desired color, and type of anodizing used. In general, it costs more upfront than painting. In most cases, painting is less expensive than anodizing. However, the cost varies depending on the type and quality of paint used, the number of coats needed, and the labor involved.

Which Is More Environmentally Friendly?

Determining which is more environmentally friendly between anodizing and painting depends on a variety of factors, but in general, anodizing has the advantage due to its lower footprint throughout its lifecycle. Here’s the breakdown:

- Chemical Usage: Anodizing primarily employs electrolytes such as sulfuric acid, chromic acid, or oxalic acid, which can be recycled and reused effectively. Painting, on the other hand, frequently uses volatile organic compounds (VOCs) in solvents and paints, which contribute to air pollution and greenhouse gas emissions.

- Waste Generation: Anodizing produces minimal waste because the oxide layer forms directly on the aluminum surface. In contrast, painting can generate waste such as paint residues, solvents, and equipment cleaning materials.

- Energy Consumption: Anodizing typically requires less energy than painting, particularly when compared to high-temperature curing techniques commonly used in paint applications.

- Metal Recycling: Because the oxide layer is a component of the metal, anodized aluminum is still recyclable. Painted aluminum, on the other hand, can be difficult to recycle because of paint residue separation and disposal issues.

Can Either Process Be Done at Home?

Both anodizing and painting have varying degrees of feasibility for home projects. While basic painting is accessible to most DIY enthusiasts, anodizing typically necessitates specialized equipment and expertise, making it a more difficult task for the home workshop. So, if you need a first-class anodizing service, please contact us.

Anodizing Requires More Gear:

- Power Supply: An adjustable DC power source is critical for providing the controlled electrical current required for anodizing. This equipment must be compatible with the electrolyte of choice while also ensuring process safety.

- Electrolyte Tank: A suitable container, typically made of non-reactive materials such as plastic or stainless steel, is required to contain the electrolyte solution and safely immerse the aluminum object.

- Electrodes: To complete the electrical circuit, an anode (positive electrode) made of conductive material such as lead or titanium is required, as is a cathode (negative electrode) made of the aluminum object itself.

- Temperature Control: Maintaining a consistent temperature in the electrolyte bath is essential for achieving optimal results. A thermometer, as well as a heating or cooling system, may be required.

- Additional Tools: Additional tools, such as clamps and hooks, as well as safety gear like gloves and goggles, are required for safe handling of equipment and chemicals.

Conclusion

The decision between anodizing and painting is based on your specific needs and priorities. If durability, scratch resistance, and corrosion protection are important, anodizing is the best option. However, if a wider range of colors, textures, and affordability are important, painting may be a better option. Finally, understanding the strengths and weaknesses of each method will allow you to make an informed decision and achieve your project’s goals.