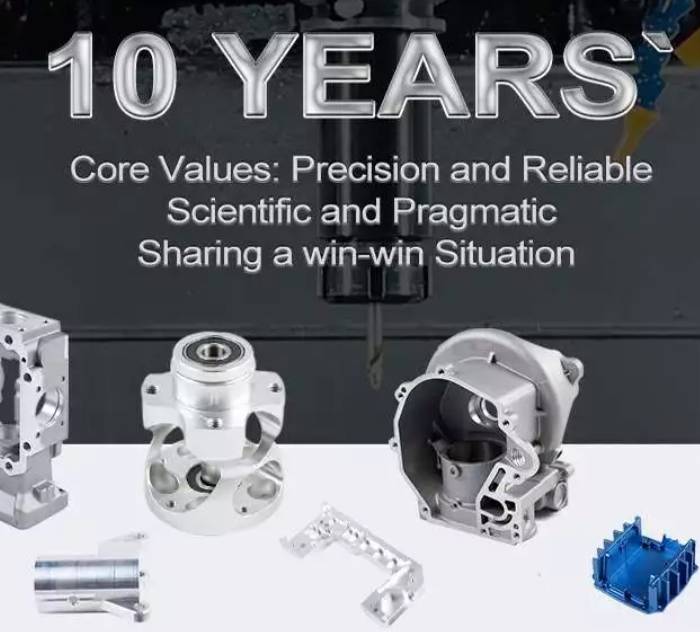

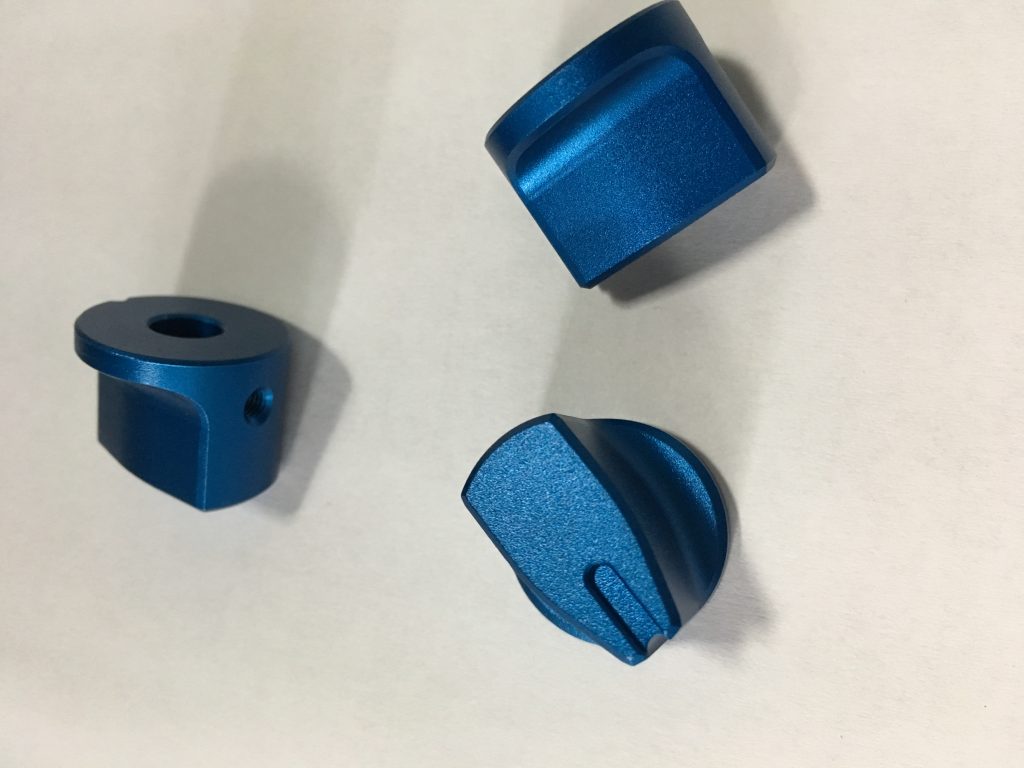

When it comes to the finishing touches in interior design, the choice of materials can significantly impact both aesthetics and functionality. Anodized aluminum knobs are a popular choice for a variety of applications due to their unique combination of durability, aesthetics, and functionality. These knobs are made from high-quality aluminum that has been subjected to an electrochemical process called anodization. This process creates a hard, protective layer on the surface of the aluminum that is resistant to scratches and corrosion, offering a myriad of benefits that extend far beyond their polished surfaces.

- Aesthetic Brilliance

Anodized aluminum knobs boast a sleek and modern appearance that can effortlessly elevate the visual appeal of any space. The anodization process not only provides a smooth and uniform finish but also allows for a wide range of color options, enabling designers and homeowners to customize their hardware to suit their unique style preferences.

- Enhanced Durability

One of the primary advantages of anodized aluminum is its exceptional durability. The anodization process creates a protective layer on the surface of the aluminum, making it more resistant to scratches, corrosion, and general wear and tear. This durability ensures that the knobs maintain their pristine appearance over time, even in high-traffic areas.

- Resistance to Corrosion

Unlike untreated aluminum, anodized aluminum is highly resistant to corrosion. This makes it an ideal choice for knobs in environments where exposure to moisture or harsh weather conditions is a concern. Kitchens and bathrooms, for example, can benefit from the corrosion-resistant properties of anodized aluminum knobs, ensuring long-lasting functionality.

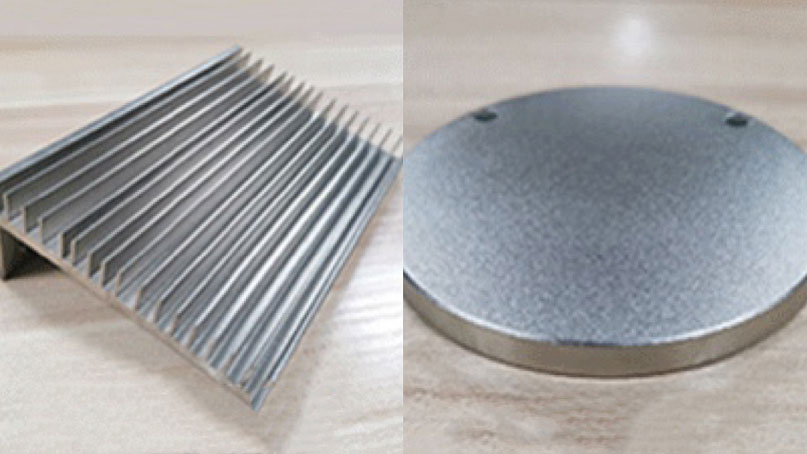

- Lightweight Yet Sturdy

Anodized aluminum knobs strike a perfect balance between lightweight design and robust construction. This makes them easy to handle while still providing a reassuring feeling of sturdiness. The lightweight nature of the material also makes anodized aluminum an excellent choice for various applications, from cabinet knobs to industrial equipment.

- Temperature Resistance

Whether in a scorching kitchen or a chilly outdoor setting, anodized aluminum knobs remain steadfast. They exhibit excellent temperature resistance, maintaining their integrity and functionality across a wide range of temperatures. This quality makes them suitable for diverse applications, including outdoor furniture and appliances.

- Low Maintenance

Anodized aluminum knobs are remarkably low maintenance, requiring minimal care to keep them looking their best. The protective oxide layer not only shields against physical damage but also makes the surface easy to clean. A simple wipe with a damp cloth is often sufficient to restore their shine, making them a practical choice for busy households.

- Eco-Friendly Option

For environmentally conscious consumers, anodized aluminum is a sustainable choice. The anodization process is generally more environmentally friendly compared to other finishing methods, producing fewer harmful by-products. Additionally, the longevity and recyclability of aluminum contribute to a reduced environmental impact.

Conclusion

In conclusion, anodized aluminum knobs transcend the ordinary, offering a host of benefits that make them a standout choice in the world of hardware. Their durability, resistance to corrosion, aesthetic versatility, and eco-friendly profile make them a compelling option for those seeking both style and substance in their design choices. As you consider the finishing touches for your next project, look beyond the surface – choose anodized aluminum knobs for a touch of sophistication that goes the extra mile.