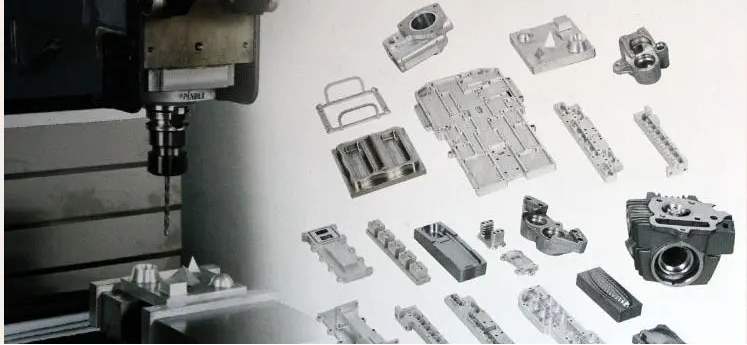

The manufacturing industry’s design and production processes evolved with the introduction and widespread use of CAD software, which eventually made its way into the CNC machining process. Drawing is more mechanized and accurate when done with CAD files, which are typically used for mechanical design and manufacturing. CAD files are essential for the manufacturing sector and the mechanical design business.

Plotting is done with 2D CAD drawings, whereas machine and fabrication work is done with 3D CAD files. When it comes to design communication, collaboration, and detailing, 3D CAD drawings offer a better user experience and allow for more exact and accurate measurements.

Why CAD is Used in CNC Machining?

Using CAD files, you can examine every component detail, including internal characteristics. The 3D model may be enlarged and rotated along any axis to help you better comprehend the part. Additionally, CAD enables the simulation of a workpiece’s movement during CNC production procedures.

What Separates 2D from 3D CAD Drawings

1. Definition

Two-dimensional computer-aided design is known as 2D CAD, whereas three-dimensional computer-aided design is known as 3D CAD.

2. Representation method

Length and height are to be displayed on a plane without depth in 2D CAD drawings. Although 3D is defined as a 3-dimensional drawing, 3D CAD drawings can depict objects with height, width, and depth.

3. Incorporate geometry

Squares, triangles, rectangles, and other geometric shapes are used in 2D CAD drawings.

Cylinders, cubes, spheres, pyramids, prisms, and other shapes are used in 3D drawings.

4. Measurement units

The standard unit of measurement for 2D charts is cm2.

Measurements for 3D drawings include quart liters and cm3 of cubic space.

5. Display

Since 2D CAD drawings are flat, designers must have a distinct vision of the finished product, which can be challenging for those without technical training.

A 3D CAD model, on the other hand, allows us to visualize the finished product and most people can comprehend the design. Additionally, showing and explaining products to consumers and employees during presentations is made simpler by the use of 3D models.

A 2D CAD drawing is what?

The most prevalent style of CAD file is a 2D drawing. It is a two-dimensional representation of the object.

Despite having all the data required to create an object, this file has no associated physical dimensions.

Advantages & Drawbacks of 2D CAD Drawing

2D drawings have advantages

1. They are applicable to a wide range of sectors, and learning the fundamentals is simple.

2. The actual drawings require less storage space and are manageable.

3. They are often used to create quick sketches of an object.

The drawbacks of 2D drawings

1. 2D CAD drawings lack depth and could result in incorrect interpretations.

2. It is difficult to visualize the design in 3D using 2D drawings.

A 3D CAD drawing is what?

Thickness is a dimension that is represented in 3D CAD drawings for objects having many dimensions. Drawings that are precise, accurate, and where all dimensions can be controlled are produced using 3D CAD models. The files also contain details about the materials, textures, and colors.

The benefits of 3D drawings

1. More control over dimensions, materials, textures, etc. is given to the user

2. The design can be viewed from any angle to give you a precise idea of the shape and details of the product.

The drawbacks of 3D drawings

The biggest disadvantage is that 3D files can be very large, particularly if they are intricate. Due to their high data volumes, it takes a long time to store and send these files.

Conclusion:

JTR can not only make CNC machining according to the drawings you provide, but also design drawings according to your needs. If you have further needs, please do not hesitate to contact us.