3D printing was called the new industrial revolution technology many years ago, so why is the voice about 3D printing getting quieter now? Is 3D printing really a technology that can lead the industrial trend? What hinders the possibility of 3D printing to achieve large-scale production?

Definition of 3D printing

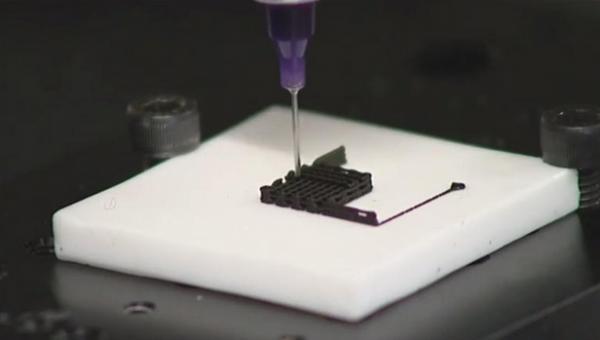

3D printing, also known as “Additive Manufacturing“, is an emerging rapid prototyping technology. Unlike traditional subtractive manufacturing processes, 3D printing is a technology in which materials are deposited or bonded layer by layer to construct three-dimensional objects based on data design files.

3D printing technology in the modern sense was born in the United States in the mid-1980s. Charles Hull (founder of 3D Systems) and Scott Crump (founder of Stratasys) are pioneers in 3D printing technology.

In the late 1980s and early 1990s, a group of small and medium-sized American technology companies, represented by 3D Systems and DTM, successively developed stereolithography (SLA), selective laser sintering (SLS) and fuse deposition modeling (FDM). and other mainstream technical routes, after more than 20 years of precipitation and continuous improvement, it has become increasingly mature.

The biggest difference between 3D printing and traditional manufacturing lies in the process of forming products. In traditional manufacturing, the entire manufacturing process generally needs to go through the process of mold opening, casting or forging, cutting, and component assembly. 3D printing eliminates the complicated process, no mold, one-time molding. Therefore, 3D printing can overcome some designs that cannot be achieved in traditional manufacturing and make more complex structures.

Why hasn’t 3D printing achieved mass production?

The reason why 3D printing cannot achieve large-scale production is that the conditions for large-scale production are not yet available. And the 3D printer is essentially a single machine, it is a way of the existing industry chain, not a direct manufacturing capability integration system.

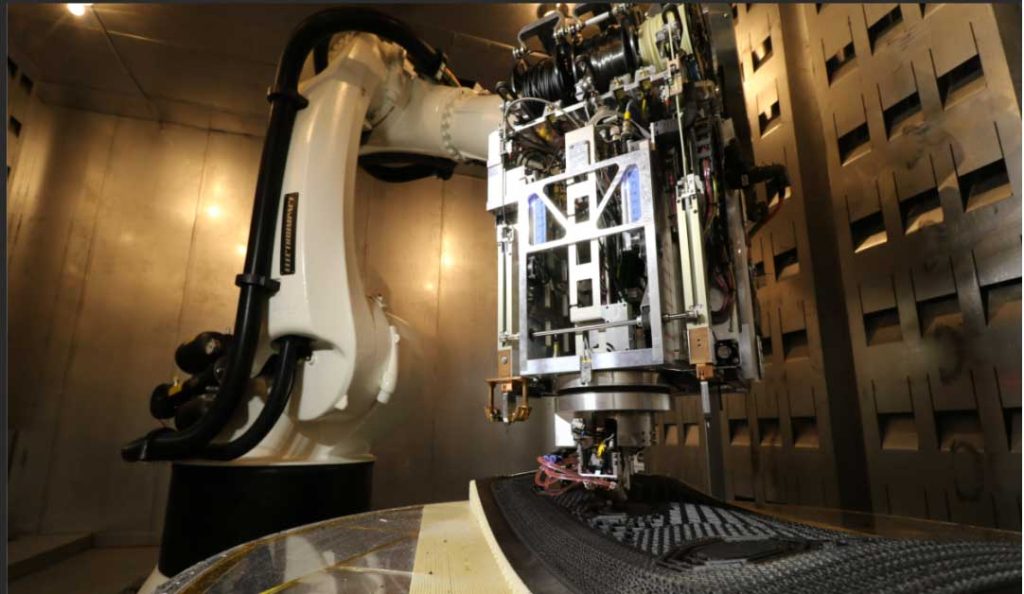

In fact, 20 or 30 years ago, 3D printing technology has been able to make products from materials such as resin. In recent years, the range of materials that can be processed by 3D printing has expanded to include metallic materials (laser sintering technology), and has successfully reorganized process technologies that existed decades ago, such as combining information technology, laser beams, etc. for surface processing of products or parts and additive manufacturing.

But as far as the current development is concerned, the development of 3D printing technology relies on the continuous improvement of the quality of key components such as lasers and electron guns.

The application of 3D printing in industry

In industrial manufacturing, the main applications of 3D printers are two.

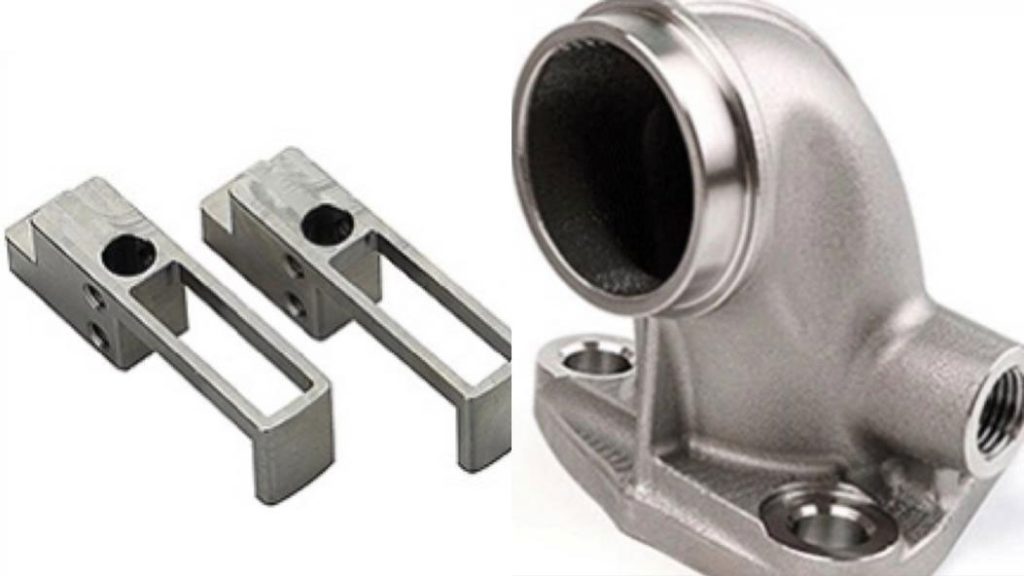

1. Some parts or finished products with complex structures are mainly finished products with high precision requirements and process details, including small parts and large components.

That is, most 3D printing technologies can breakthrough structural geometric constraints. And therefore, in the processing of large-scale components of certain structures, not only the process difficulty is reduced compared to the traditional ones, but the cost is also reduced.

For example, the so-called Laser Additive Manufacturing, traditionally, the fuselage frame of the F-22 is made of titanium alloy forgings. Due to the superposition technology of LAM, it saves 90% of very expensive raw materials, and does not require special manufacturing. For molds, the processing cost, which was originally equivalent to 1~2 times the material cost, now only needs 10% of the original. It is roughly estimated that the cost of processing a 1-ton titanium alloy complex structure is about 25 million yuan, and the cost of LAM is only much lower than that of the traditional process.

2. Emergency or quick-to-manufacture products for certain industries.

The simplest is military, giving the mechanical maintenance team to process some finished products on site to ensure the maintenance of the mechanical platform in emergency situations.

In most cases, after land battle tanks and armored vehicles are damaged, more than a certain percentage are directly abandoned due to cost reasons. 3D printing can solve these problems, of course, during the march, when the logistics are tight, not to mention the rapid production of some supplies.

For example, the most famous in the medical field is to use 3D printing to print high-precision models to assist treatment. For example, Stratasys Solidoodle 2 can be used to print models of internal organs or tissues of patients to assist in the formulation of precise surgical plans. Without the need for external limbs that are compatible with biological tissue, medical 3D printing enables deep customization.

In vitro medical devices include medical models, medical devices such as prosthetics, hearing aids, templates for dental surgery, etc. According to statistics from the American organization Amputee Coalition, about 2 million people in the United States are currently using 3D printed prosthetics.

Reasons why 3D printing can’t scale

1. The efficiency of the production model

The efficiency of the integrated molding of monomers is definitely not comparable to the efficiency of “classified parts processing + assembly in the industry”, because the latter is mobilizing the production capacity of the entire manufacturing system, and the processing of semi-finished products and grading can improve the efficiency of the process. To almost the highest, it is equivalent to the formation of an assembly line in the entire industry.

However, with the integrated molding of the single body, the workflow is completely fixed, and such an industrial effect cannot be formed, and the current 3D printer body cannot withstand long-term, high-intensity loads. In addition, the maintenance cost and difficulty of single machine production are far higher than the traditional process of spreading the industrial chain evenly.

2. Applicability of 3D printing materials

The first is the process problem caused by the material application.

Because special metal powders need to be made in advance; the density of printed metal products is low, up to 98% of the density of castings, and in some cases lower than the mechanical properties of forgings, of course, in some components, such as large Titanium alloy components (such as the relatively hot aviation industry) can fully meet the mechanical properties, but the overall situation is debatable; some printed products have poor surface quality and accuracy of 2-10μm, which requires post-processing such as grinding and polishing; Support material is difficult to remove when 3D printing parts with complex curved surfaces.

3. Higher cost than traditional CNC machining

Of course, this cost is mainly due to the maintenance cost of the single machine running at high load for a long time as mentioned earlier, resulting in the high cost of large-scale production.

There is also the cost of materials. The model of deep customization of part type is actually not a low-cost production model with a broad market.

Will 3D printing also disrupt production?

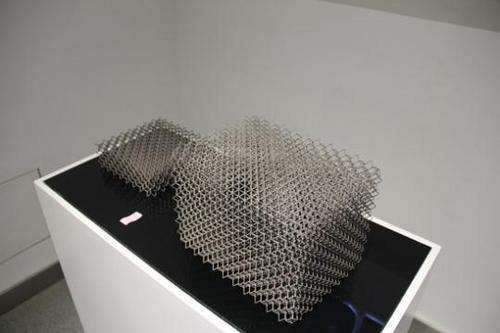

3D printing cannot become a mainstream production method due to its inability to achieve mass production. But this does not mean that 3D printing will not become a better part of processing and a new trend in product processing in the future.

The primary problem now is that the current 3D printing industry needs to accurately locate the market type and audience of its products, and promote the market within the industry. Additive manufacturing has to develop a new world in its own new field. That is, the advantages and concepts of full additive manufacturing, developing their own proprietary applications and markets.