Titanium is becoming a more popular machining material for the CNC machining field. Because these machined parts are being applied in many fields, especially aerospace, new energy car, and even military, etc. And I believe that there will be more according to the trend. So you might wonder how does a professional CNC machining manufacturer works on a huge scale of titanium parts machining? This article will show you how JTR works on them.

1. Enlarge The Applications of Titanium Machining Parts – Advanced CNC Machining Technology

To comprehensively improve the application-based CNC machining technology, it is necessary for industrial enterprises to pay attention to the importance of CNC machining technology improvement, and increase investment in the research and development of CNC machining technology, so as to ensure that the improvement of CNC machining technology can achieve the corresponding effect.

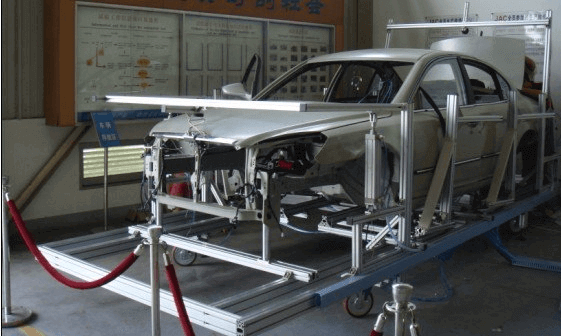

JTR has achieved the technology improvement of the CNC machining application, which can maximize the production quality of titanium alloy precision castings, and at the same time can speed up production efficiency on the basis of CNC machining cost, and with the continuous optimization and improvement of CNC machining technology, It can also solve the problems and difficulties in the application CNC machining process while improving the application degree of CNC machining technology, so as to further realize the production and processing of some larger and more complex titanium alloy precision castings.

2. Choose the Most Suitable Machine Tool to Ensure the Quality of CNC Machining

When building a CNC machining production line for large titanium alloy castings, there are many types of machine tools to choose from, among which EDM machines and milling machines are the most widely used types.

In order to ensure the actual production efficiency and product quality of the production line, and reduce the number of subsequent adjustments and maintenance, paying full attention to the selection of CNC machine tools is the secret to success. Since there are many types of large titanium alloy precision castings, and the structure of the castings is often complex, the processing is difficult. Therefore, the corresponding production processes of different types of titanium alloy precision castings are also quite different. In order to be able to produce titanium alloy precision castings in a fine CNC tolerance, and with high quality in the actual production process, and to meet the actual production requirements as much as possible to compress the production cost, it is necessary to comprehensively classify the types of large titanium alloy precision castings to be produced to ensure the actual production effect.

Due to the classification of titanium alloy precision castings, the corresponding CNC machine tools also need to be selected when designing the production line. Only by choosing the most suitable CNC machine tool can we ensure that the CNC machining titanium process can be carried out smoothly and stably, thus ensuring the actual production efficiency and basic production quality of large titanium alloy precision castings.

3. Improve the Accuracy of Titanium Alloy Precision Castings, Thereby Effectively Improving the Machining Quality

In the actual production practice, the traditional processing method of precision castings gradually exposed its existing problems and deficiencies. The traditional precision casting processing method takes a long time to process and produce, but the quality of the obtained precision castings is often very unstable, and it is easy to produce a large number of low-quality products, wasting a lot of raw material resources. Moreover, due to the limitation of the manufacturing process, the obtained casting products still have the disadvantage that they are not fine enough and cannot meet the processing requirements of precision castings. Under the background that people’s requirements for industrial production are gradually increasing, such as short CNC time, the traditional precision casting processing technology cannot meet the production needs at all, which has seriously affected the overall development of precision casting production enterprises and even caused them to be unable to effectively use raw materials such as titanium alloys. Lead to further weakening of its market competitiveness.

In the process of widely applying science and technology to all walks of life, the application of CNC machining technology in the processing of large titanium alloy precision castings has achieved good results. At the same time of innovation in the industrial market, in order to ensure that the CNC machining technology has sufficient market vitality, it is also necessary to optimize and reform the CNC machining technology. Among them, the improvement of the machining quality and CNC machining accuracy of titanium alloy precision castings is the main challenge of CNC machining technology innovation. The fineness and quality of large-scale titanium alloy precision castings are a direct reflection of the quality of production and processing technology. Only by paying attention to the quality and fineness of the finished products and optimizing the CNC machining technology can the overall progress of the industrial industry be truly realized.

4. Deeply Optimize the Precision Casting Production Line and Strengthen the Application of CNC Machining Technology

The in-depth optimization of the CNC machining production line is a direct method to ensure the production and processing efficiency of the CNC machining production line and strengthen the application effect of the CNC machining technology. Since the application effect of CNC technology is affected mainly by the programming level of CNC machining technology, in order to deeply optimize the CNC machining production line and improve the processing quality of large titanium alloy castings, it is necessary for programmers to program CNC programming according to actual needs. The program is modified and adjusted in a targeted manner. Programmers need to fully consider the three main factors of processing sequence, processing time, and processing quality so that the entire production line can complete the production and processing work according to the relevant instructions so as to effectively improve the application effect of CNC machining technology and improve large-scale titanium alloy castings production process.

One of The Most Powerful CNC Machining Manufacturers

There is no doubt machining with Titanium is a big deal, but for JTR, which specializes in CNC milling service, CNC turning service, and metal casing service, it can be solved by our professional team and advanced machining tools. Either a small case of CNC titanium parts or a big one can both be managed well. If you are looking for one titanium machining manufacturer, look no further, please contact us.