The accuracy is an essential factor of the CNC machining’s performance, as the final machining accuracy and machining efficiency of the workpiece, in addition to the reasons of the CNC machine itself, should also be based on reasonable machining route setting, tool selection, and correct installation, reasonable selection of cutting amount, programming skills and rapid control of dimensional accuracy. You may want to know how can the workpieces be controlled at a proper accuracy, this article will let you know how they can be approved.

What is Machining Accuracy?

Explain this concept in simple terms. Accuracy refers to the difference between the actual measurement value and the system measurement value. If the difference between the two is very small, then the accuracy of the measurement is high.

CNC machining is a project working based on CNC programming. A tiny change of machining program can directly affect the final machining accuracy and efficiency of the machining tool. The start of the accuracy can start from the clever use of intrinsic programs, reduction of cumulative errors in CNC systems, and flexible use of main programs and subroutines. There are 5 ways to improve a CNC machining workpiece accuracy:

5 Ways to Improve Accuracy of CNC Machining Workpiece

1. Getting a Perfect with Experienced Programming Skills

CNC programming is the most basic work in CNC machining. An experienced programmer, he knows how to write a good program. He can cleverly use the inherent program, avoid the cumulative error of the CNC system, and use the main program and subroutine flexibly.

In the process of complex mold processing, we generally adopt the form of multi-piece processing. If there are several of the same shape, the relationship between the main program and the subprogram should be used, and the subprogram should be used repeatedly in the main program until the processing is completed. So as to ensure the consistency of the processing size and improve the processing efficiency.

Incremental computing, also famed as incremental computation, is a software feature that tries to save time by recomputing only those outputs that depend on the changed data when data changes. We often use incremental calculations to write programs, but continuous execution of multiple programs will produce a certain cumulative error. Now the absolute computing is applied by us to write the program, it can help reduce the cumulative error of the CNC system, also ensure the machining accuracy.

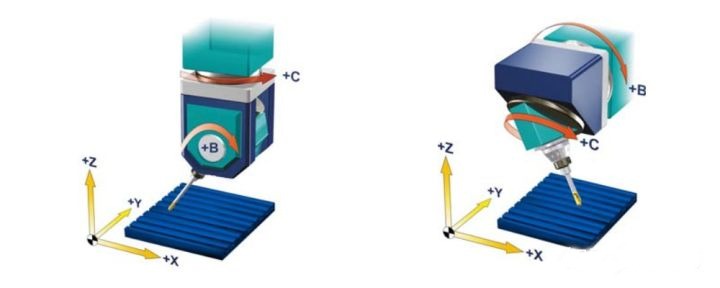

2. Optimized Machining Strategies

Employing appropriate machining parameters such as cutting speed, feed rate, and depth of cut optimizes material removal rates while maintaining accuracy.

Utilizing advanced cutting strategies such as high-speed machining, trochoidal milling, and adaptive toolpaths improves tool life and surface finish while reducing machining time.

Implementing adaptive control systems and dynamic toolpath adjustments based on real-time feedback optimize machining processes and enhance accuracy. Here are 2 ways we often use for batch production:

- Trial cut: adjust the blade extension base on the feature of the material, and then apply the same material used in your project to perform a trial cut. It is often used for single-piece small batch production.

- Adjustment position: after adjusting the relative position of the machine tool, fixture, workpiece, and cutting tool, the size can be known. We often use it for mass production.

3. Reducing the measurement errors

Selecting high-quality cutting tools appropriate for the material being machined is crucial for accuracy. Carbide or high-speed steel tools with proper coatings enhance tool life and maintain cutting edge sharpness.

Tool condition monitoring systems can detect wear and damage early, allowing for timely tool replacement and minimizing dimensional inaccuracies.

Maintaining proper tool geometry and edge sharpness through regular regrinding or replacement prevents surface finish issues and dimensional errors.

Understanding material properties such as hardness, thermal conductivity, and machinability is essential for achieving accurate machining results.

Designing workpieces with appropriate tolerances and allowances reduces the risk of dimensional variations and ensures compatibility with CNC machining capabilities.

Consideration of part orientation, fixture design, and support structures minimizes distortion and improves dimensional stability during machining.

4. Machine Calibration and Maintenance

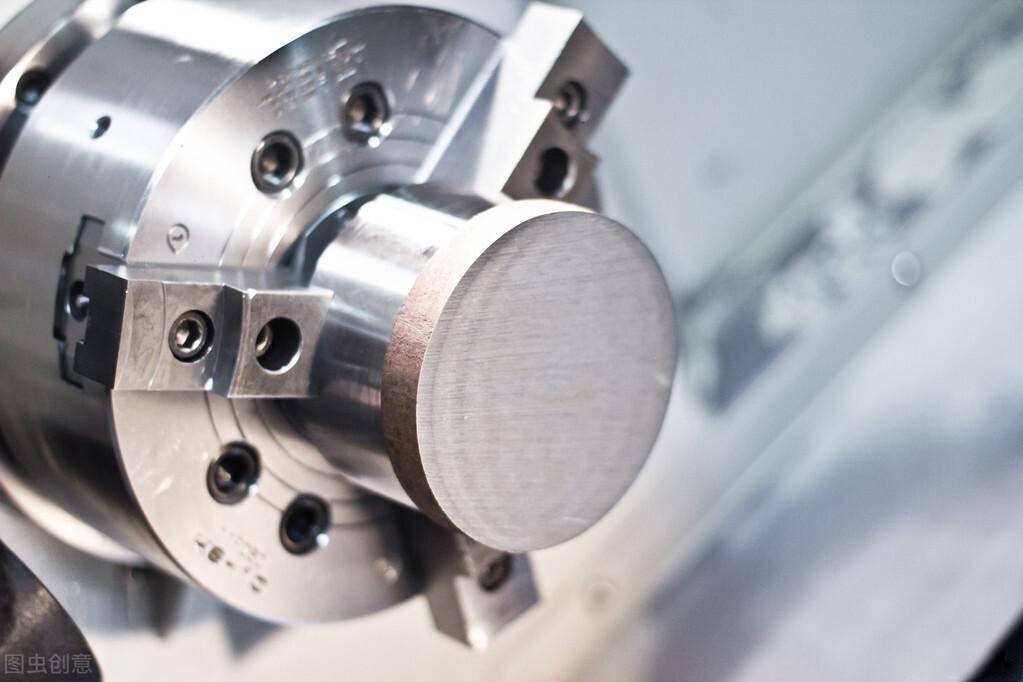

Regular calibration of CNC machines is essential to ensure accuracy. This involves aligning axes, checking spindle concentricity, and verifying machine geometry.

Scheduled maintenance tasks such as lubrication, cleaning, and inspection of critical components help prevent wear and maintain machine performance.

Implementing preventive maintenance schedules reduces the risk of unexpected downtime and ensures consistent accuracy over time.

5. Real-Time Monitoring and Feedback Systems

Implementing sensor-based monitoring systems for tool wear, spindle vibration, and temperature variations enables real-time detection of machining anomalies and prevents quality deviations.

Integration of in-process metrology systems such as probing and laser measurement devices facilitates on-machine inspection and feedback loop adjustment for improved accuracy.

Utilizing data analytics and machine learning algorithms to analyze machining data and optimize process parameters enhances accuracy and productivity over time.

Conclusion

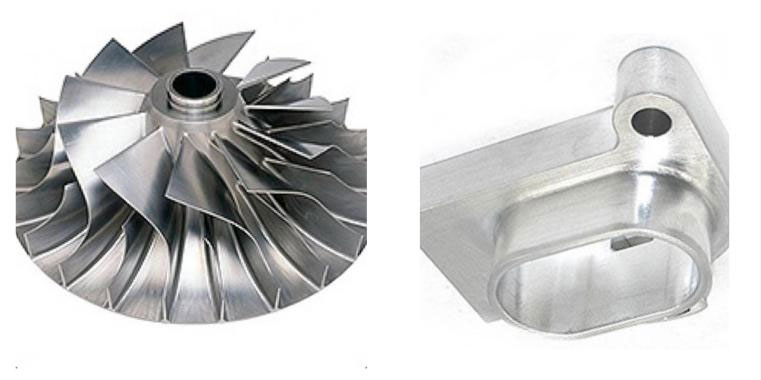

Known workpiece error consists of two parts: machine tool error (including geometric error and thermal induced error) and cutting induced error. By implementing these strategies in CNC machining operations, manufacturers can achieve higher levels of accuracy, consistency, and efficiency in producing precision-engineered components. Continuous improvement efforts and technological advancements further enhance the capabilities of CNC machining systems for meeting increasingly stringent quality requirements in diverse industries.